3.50

9928487 R01 - 2018 RANGER XP 1000 Service Manual

© Copyright Polaris Industries Inc.

NOTE

Always replace plain bearings when the crankcase or

connecting rods have been disassembled. Refer to and

BEARING SELECTION IDENTIFICATION LETTERS

AND NUMBERS

procedures.

CYLINDER INSPECTION

1. Lay a straight edge

q

across the top surface of the

cylinder at several different points and measure warp

by inserting a feeler gauge between the straight edge

and the cylinder surface. If warp exceeds the service

limit, replace the cylinder.

MEASUREMENT

Cylinder Warp Limit:

.002″ (0.05 mm)

2. Inspect cylinder for wear, scratches, or damage.

IMPORTANT

DO NOT hone the cylinders or attempt to repair a

damaged cylinder by honing.

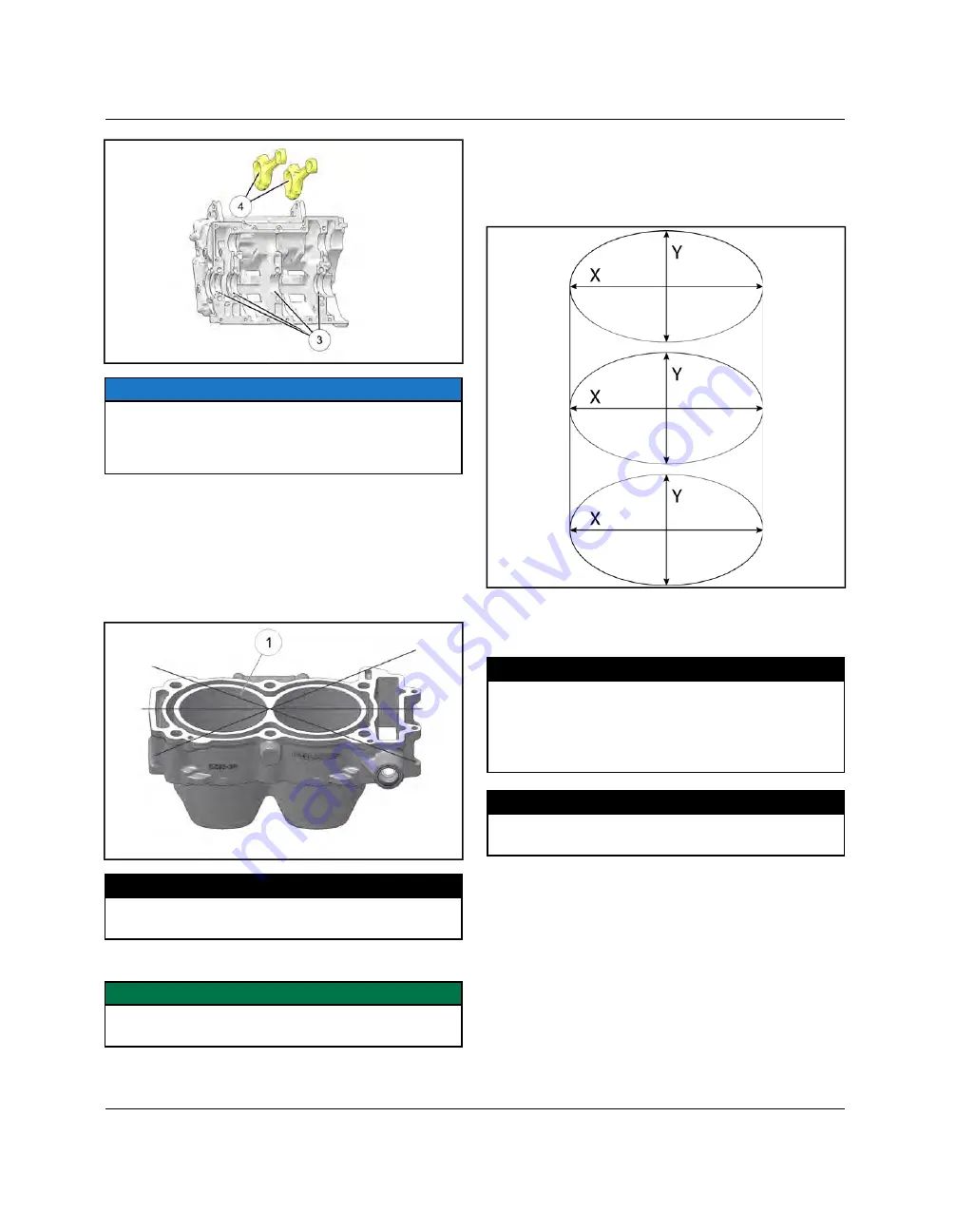

3. Inspect taper and out of round with a dial bore gauge.

4. Inspect cylinder for taper and out of round with a

telescoping gauge or a dial bore gauge. Measure in

two different directions, front to back and side to side,

on three different levels (1/2” down from top, in the

middle, and 1/2” up from the bottom).

5. Record measurements. If cylinder is tapered or out of

round beyond specification, the cylinder must be

honed, bored or replaced.

MEASUREMENT

Cylinder Taper:

.001″ (0.025 mm)

Cylinder Out of Round:

.001″ (0.025 mm)

MEASUREMENT

Standard Bore Size:

3.6614 ± .0003" (93 mm ± 0.008 mm)