9928487 R01 - 2018 RANGER XP 1000 Service Manual

© Copyright Polaris Industries Inc.

3.101

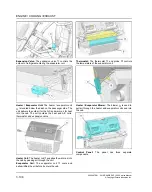

HVAC SYSTEM OVERVIEW

AIR CONDITIONING DESCRIPTION

In an air conditioning system heat is removed from the cab by circulating R-134a refrigerant through a closed system

containing five major components. At these five points in the system the refrigerant goes through pressure and

temperature changes.

The compressor takes in heated, low pressure refrigerant gas through the suction valve (low pressure side) and

pressurizes the heated refrigerant and forces it through the discharge valve (high pressure side) on the condenser.

Should the pressure on the high pressure side become too high, the HPCO (High Pressure Cut-Out) switch will cycle

the compressor clutch off.

Ambient air passing through the condenser removes the heat from refrigerant resulting in physical state change in the

refrigerant from a gas to a liquid.

The liquid refrigerant moves on to the receiver / drier where impurities such as moisture and dirt are filtered out. The

receiver / drier also serves as the storage tank for the liquid refrigerant. The liquid refrigerant (still under high pressure)

flows to the expansion valve.

The expansion valve meters the amount of refrigerant into the evaporator coil. As the refrigerant passes through the

expansion valve, an extreme pressure and temperature drop occurs. It becomes a low temperature, low-pressure

liquid and saturated vapor. The low pressure liquid immediately starts to boil and vaporize as it enters the evaporator.

The warmer air of the machine's cab is drawn through or blown into the evaporator by the evaporator blower.

Since the refrigerant is colder than the air, it absorbs the heat from the air and produces cooled air, which is pushed

into the cab by the blower. The moisture in the air condenses on the evaporator coil and drips into the drain pan, which

directs the water out of the cab.

The refrigerant cycle is completed when the heated low pressure gas is again drawn into the compressor. The

compressor cycles on and off to maintain the desired cab temperature. The Electronic De-icing Thermostat is a micro

controller based module that measures evaporator coil temperature and cycles the compressor clutch to maintain a

constant evaporator pressure.