9928487 R01 - 2018 RANGER XP 1000 Service Manual

© Copyright Polaris Industries Inc.

3.115

COMPRESSOR OIL INSPECTION

The compressor oil should be checked as follows when

oil is being added to an in service utility work machine.

There is a close affinity between oil and refrigerant.

During normal operation, part of the oil circulates with the

refrigerant in the system. Therefore, when checking the

amount of oil in the system or replacing any system

component, the compressor must be run in advance to

insure return of oil to the compressor.

If the amount of refrigerant in the system has decreased,

charge the system.

1.

Open the cab door and windows.

2.

Run the blower at maximum speed.

3.

Run the compressor for at least 20 minutes at idle.

4.

Remove the compressor from the vehicle.

5.

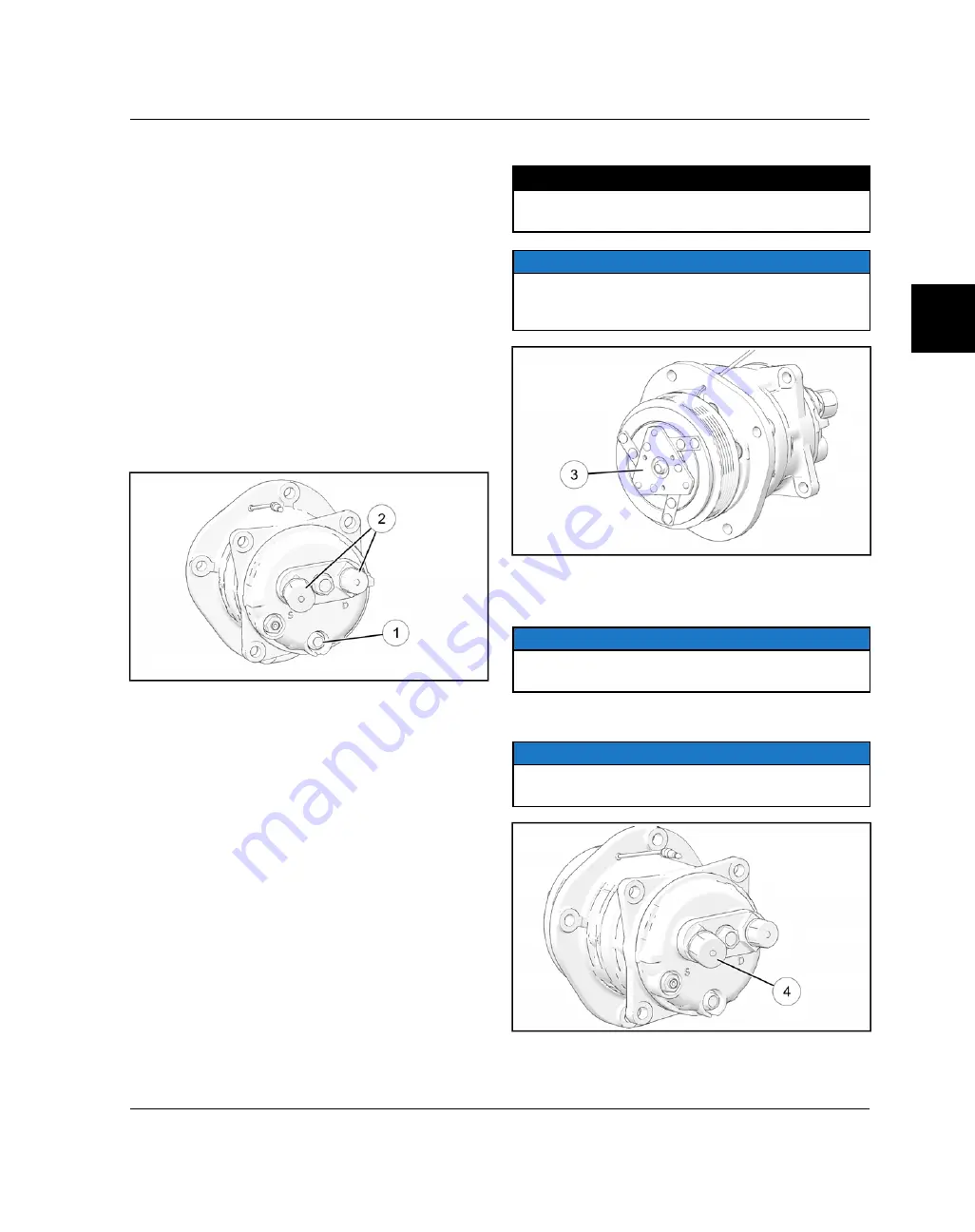

Remove the oil drain plug

q

and drain the oil

through the connectors

w

and the oil drain hole.

6.

Tighten the oil drain plug to specification.

TORQUE

Compressor Oil Drain Plug:

10 ft-lb (14 Nm)

NOTE

Extract the remaining oil through the discharge-side

connector by rotating the drive pulley

e

several times

by hand.

7.

Measure the drained oil in a measuring cylinder.

8.

Check the oil for contamination, dirt, metal shavings,

or varnish color, discard the oil if contaminated.

NOTE

If metal shavings are found in the compressor oil,

replace the compressor assembly.

9.

Add new compressor oil through the suction side

connector

r

. Add 150 - 170 cc's of PAG 100 oil.

NOTE

The suction port on the compressor is marked with an S

and is the larger.