ENGINE

3.59

PUMP SHAFT END PLAY ADJUSTMENT

1.

Make sure the pump shaft bearing is firmly seated

in the Magneto side crankcase.

2.

Measure the distance from the magneto crankcase

mating surface to the bearing using a dial caliper

and a straight edge. Subtract the thickness of the

straightedge and record.

3.

Install the gear on the oil pump and measure the

width of the pump and gear. Subtract this

measurement from the measurement recorded in

Step 2.

4.

Subtract the thickness of the existing shim from the

result of Step 3 to determine if a different shim is

needed.

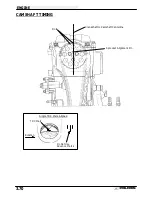

PUMP SHAFT OIL SEAL INSTALLATION

1.

Install the seal from the outside of the crankcase

(water pump side) with the spring facing inward,

toward the pump shaft bearing.

2.

Drive or press the seal into place using a 25mm

(.985

″

) seal driver, until flush with the outer edge of

the seal bore.

3.

Lubricate the seal lip with grease.

Pump Shaft End Play:

.008

″

-.016

″

(.02-.04 cm)

Summary of Contents for Sportsman 400

Page 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Page 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Page 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

Page 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

Page 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Page 372: ...ELECTRICAL 10 38 NOTES ...

Page 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Page 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Page 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...