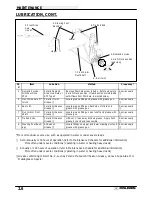

MAINTENANCE

2.2

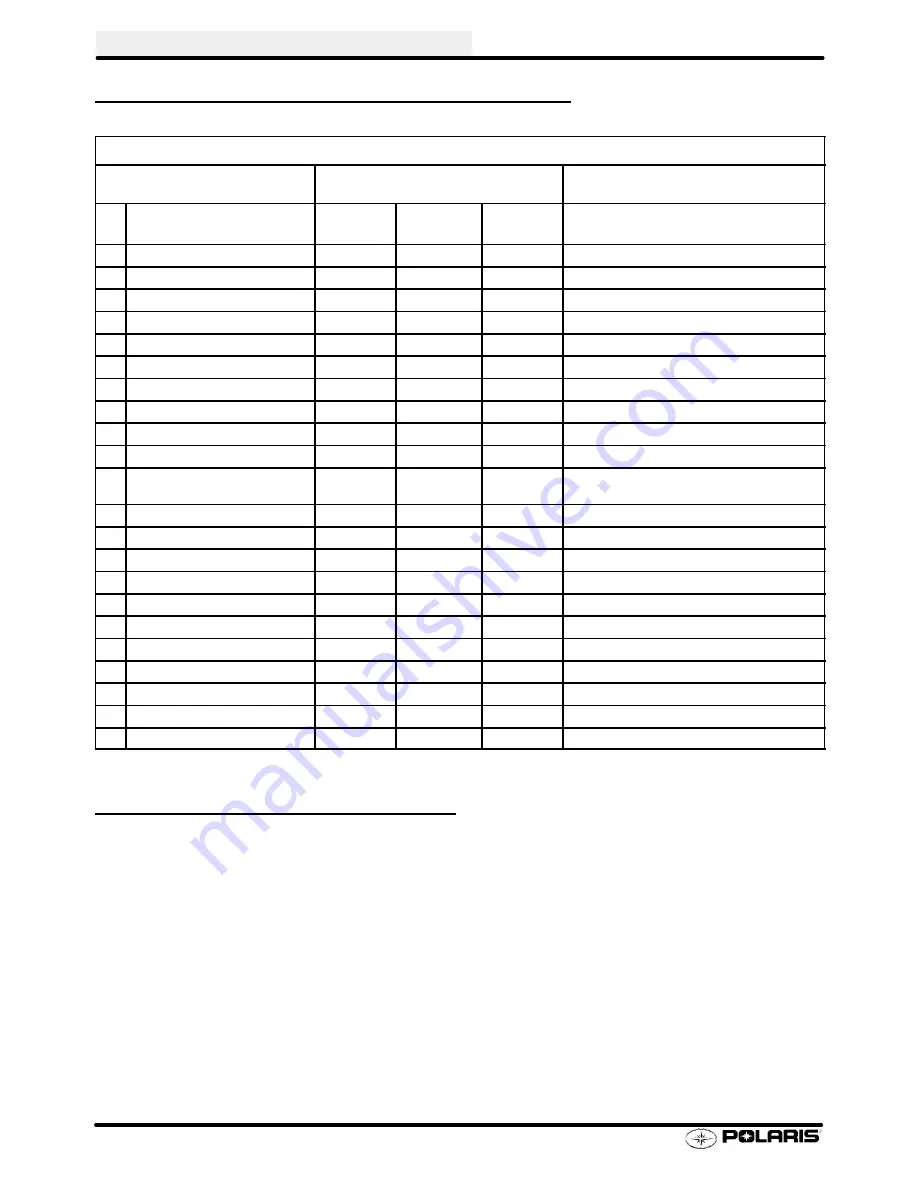

PERIODIC MAINTENANCE CHART, CONT.

CHASSIS

Frequency

(Whichever comes first)

Item

Hours

Calendar

Miles

(Km)

Remarks

"

General Lubrication

50 hrs

3 months

500 (800)

Lubricate All Fittings, Pivots, Cables, Etc.

"

Front Hubs/Fluid Check

50 hrs

6 months

500 (800)

Check monthly

"

Front Hubs/Fluid Change

100 hrs

12 months

1000 (1600)

Check monthly

"

Front Gearcase Lubricant

100 hrs

12 months

1000 (1600)

Inspect Monthly; Change Annually

Drive Belt

50 hrs

6 months

500 (800)

Inspect - Adjust, Replace if Necessary

Clutches (Drive And Driven)

100 hrs

12 months

1000 (1600)

Inspect, Clean

"

Transmission Oil Level

25 hrs

Monthly

250 (400)

Inspect Monthly; Change Annually

Shift Linkage

50 hrs

6 months

500 (800)

Inspect,Lubricate, Adjust

Shift Selector Box

200 hrs

24 months

2000 (3200)

Change Lubricant Every Two Years

H

Steering

50 hrs

6 months

500 (800)

Inspect Daily, Lubricate

H

Toe Adjustment

As required

As required

Periodic Inspection, Adjust When Parts are Re-

placed

"

Front Suspension

50 hrs

6 months

500 (800)

Inspect - Lubricate

"

Rear Suspension

50 hrs

6 months

500 (800)

Inspect - Lubricate

Tires

Pre-ride

Pre-ride

Inspect Daily, Pre-Ride Inspection Item

H

Brake Fluid

200 hrs

24 months

2000 (3200)

Change Every Two Years

"

Brake Fluid Level

Pre-ride

Pre-ride

Inspect Daily, Pre-Ride Inspection Item

"

Brake Lever Travel

Pre-ride

Pre-ride

Inspect Daily, Pre-Ride Inspection Item

H

Brake Pad Wear

10 hrs

Monthly

100 (160)

Inspect Periodically

Auxiliary Brake Adjustment

As required

As required

Inspect Deflection Daily; Adjust

Brake System

Pre-ride

Pre-ride

Pre-Ride Inspection Item

Wheels

Pre-ride

Pre-ride

Pre-Ride Inspection Item

Frame Nuts, Bolts, Fasteners

Pre-ride

Pre-ride

Pre-Ride Inspection Item

PRE-RIDE / DAILY INSPECTION

Perform the following pre-ride inspection daily, and when servicing the vehicle at each scheduled maintenance.

S

Tires - check condition and pressures

S

Fuel and oil tanks - fill both tanks to their proper level; Do not overfill oil tank

S

All brakes - check operation and adjustment (includes auxiliary brake)

S

Throttle - check for free operation and closing

S

Headlight/Taillight/Brakelight - check operation of all indicator lights and switches

S

Engine stop switch - check for proper function

S

Wheels - check for tightness of wheel nuts and axle nuts; check to be sure axle nuts are se-

cured by cotter pins

S

Air cleaner element - check for dirt; clean or replace

S

Steering - check for free operation noting any unusual looseness in any area

S

Loose parts - visually inspect vehicle for any damaged or loose nuts, bolts or fasteners

S

Engine coolant - check for proper level at the recovery bottle

Summary of Contents for Sportsman 400

Page 6: ...SPORTSMAN 400 A01CH42AC GENERAL INFORMATION 1 4 MODEL COLOR IDENTIFICATION ...

Page 21: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 19 TORQUE CONVERSIONS ...

Page 22: ...Newton Meter to Pound Foot and Pound Inch GENERAL INFORMATION 1 20 TORQUE CONVERSIONS ...

Page 152: ...Forward FUEL SYSTEM CARBURETION 4 2 FUEL TANK ASSEMBLY ...

Page 366: ...ELECTRONIC SPEEDOMETER WIRING DIAGRAM ELECTRICAL 10 32 ...

Page 372: ...ELECTRICAL 10 38 NOTES ...

Page 379: ...ELECTRICAL 10 39 WIRING DIAGRAM 2001 SPORTSMAN 400 ...

Page 380: ...ELECTRICAL 10 40 WIRING DIAGRAM 2001 SPORTSMAN 500 EARLY ...

Page 381: ...ELECTRICAL 10 41 WIRING DIAGRAM 2001 SPORTSMAN 500 LATE ...