FUEL SYSTEM / FUEL INJECTION

4.15

THROTTLE POSITION

SENSOR (TPS)

The throttle position sensor (TPS) is used to indicate

throttle plate angle to the ECU.

Mounted on the throttle body and operated directly off

the end of the throttle shaft, the TPS works like a

rheostat, varying the voltage signal to the ECU in

direct correlation to the angle of the throttle plate. This

signal is processed by the ECU and compared to the

internal pre--programmed maps to determine the

required fuel and ignition settings for the amount of

engine load.

NOTE:

The correct position of the TPS is

established and set at the factory. Do not loosen

the TPS or alter the mounting position. If the TPS

is repositioned, replaced or loosened it must be

recalibrated.

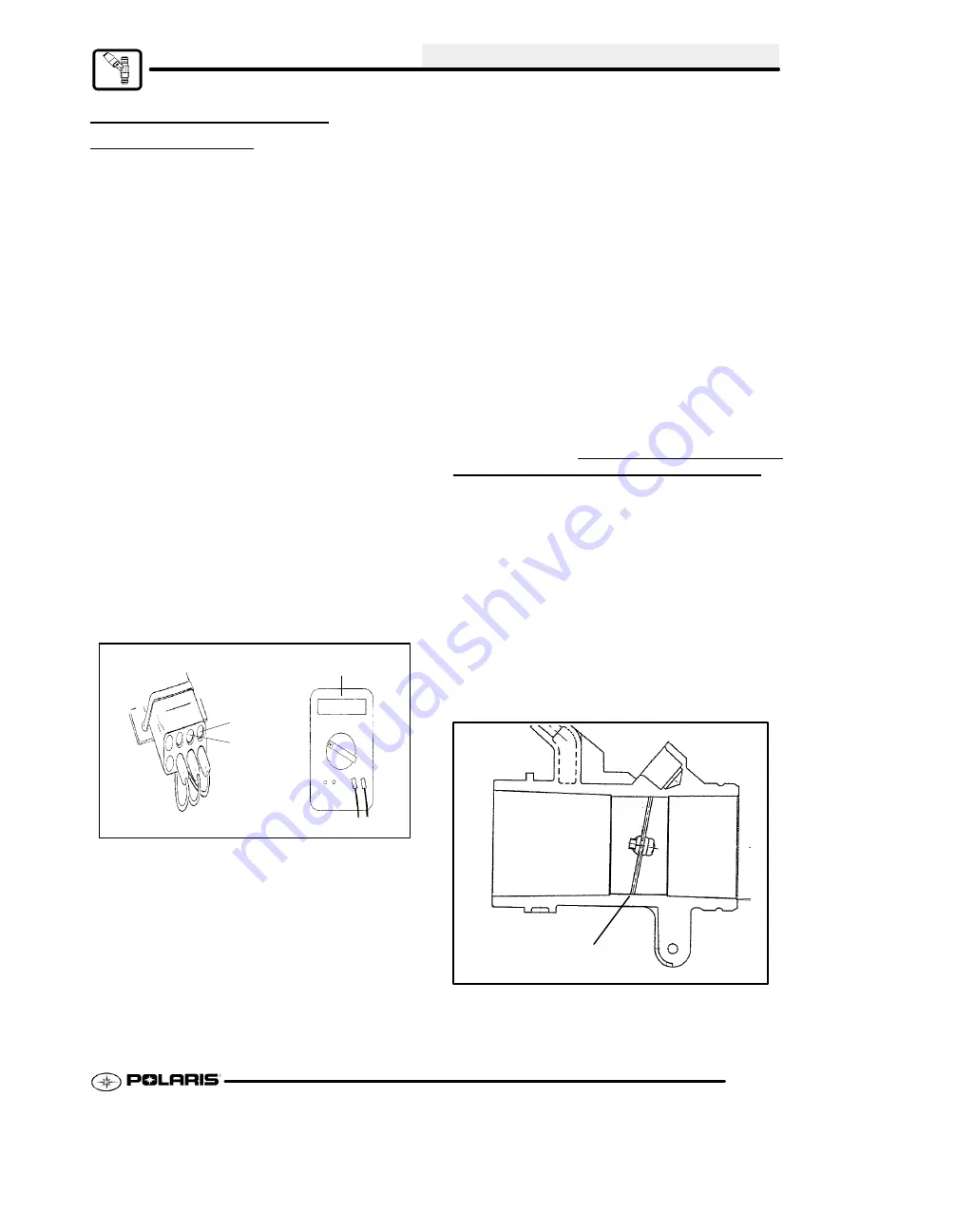

THROTTLE POSITION SENSOR TEST

The throttle position sensor (TPS) is a non--serviceable

item. If it is faulty, it must be replaced. It can be tested

using the following method:

G

Set up the TPS voltage check tool,

PN PU--47082, according to the

instructions. Make sure that the 9 volt

battery has a minimum of 6 volts.

Figure 2

.

Figure 2

Red

Pink

Black

No ’Jumps’ in read--out

.70--.99v

Vdc

Black Probe

Red Probe

Tool PN PU--47082

R Y

BK

G

With the test leads connected and

the meter set, move the throttle open

and closed slowly while reading the

display. The voltage should increase

smoothly

with

no

’jumps’

or

decreases when the throttle is

applied.

G

If the sensor does not function

correctly, replace it.

THROTTLE POSITION SENSOR

REPLACEMENT

The correct position of the TPS is established and

set at the factory. If the TPS is repositioned,

replaced or loosened it must be recalibrated.

1. Remove the front fender assembly and fuel tank.

2. Disconnect sensor from the harness.

3. Loosen and rotate the throttle body to gain access

to the retaining screw.

4. Remove the retaining screw and replace the

sensor.

5. Refer to “TPS Initialization” for setting the TPS

voltage.

THROTTLE POSITION SENSOR

INITIALIZATION

The correct position of the TPS is established and

set at the factory. Use this procedure only if the

TPS was repositioned, replaced or loosened.

This set procedure can be accomplished with the

throttle body attached to the engine. This

procedure is meant to allow the TPS flow and idle

offset voltage to be correctly set without the use of

a flow bench. No steps can be eliminated.

Step 1

Establishing zero offset voltage:

This step is

crucial as it sets the TPS position using a fixed

physical stop. This will insure that the correct offset

voltage is reached once the correct throttle body flow

is set.

Figure 1

Throttle Plate

must be closed

G

Remove cover and disconnect

throttle cable from throttle cam.

Summary of Contents for Sportsman 800 Efi 2005

Page 116: ...ENGINE 3 62 NOTES ...

Page 136: ...FUEL SYSTEM FUEL INJECTION 4 20 NOTES ...

Page 186: ...CLUTCH 6 30 NOTES ...

Page 256: ...BRAKES 9 24 NOTES ...

Page 292: ...ELECTRICAL 10 36 BASIC WINCH WIRING 2005 ATV MODELS 2005 ATV WINCH WIRING DIAGRAM ...

Page 300: ...ELECTRICAL 10 44 NOTES ...

Page 301: ...ELECTRICAL 10 39 WIRING DIAGRAM 2005 SPORTSMAN 700 800 EFI Stator ...

Page 302: ...ELECTRICAL 10 40 WIRING DIAGRAM 2005 SPORTSMAN 700 800 EFI ...