9.27

BRAKES

9

Overview

Polaris disc brake systems are light weight, low maintenance

and perform well in the conditions ATV’s routinely encounter.

However, there are a few things to remember when replacing

disc brake pads or performing brake system service to ensure

proper system function and maximum pad service life.

• Perform a brake burnishing procedure after installing

new pads to maximize service life.

• Optional pads are available to suit conditions in your

area. Select a pad to fit riding style and environment.

• Do not over-fill the master cylinder fluid reservoir.

• Make sure the brake lever and pedal returns freely and

completely.

• Adjust stop pin on caliper (if applicable) after pad

service.

• Check and adjust master cylinder reservoir fluid level

after pad service.

• Make sure atmospheric vent on reservoir is

unobstructed.

• Test for brake drag after any brake system service and

investigate cause if brake drag is evident.

• Make sure caliper moves freely on guide pins (where

applicable).

• Inspect caliper piston seals for foreign material that

could prevent caliper pistons from returning freely.

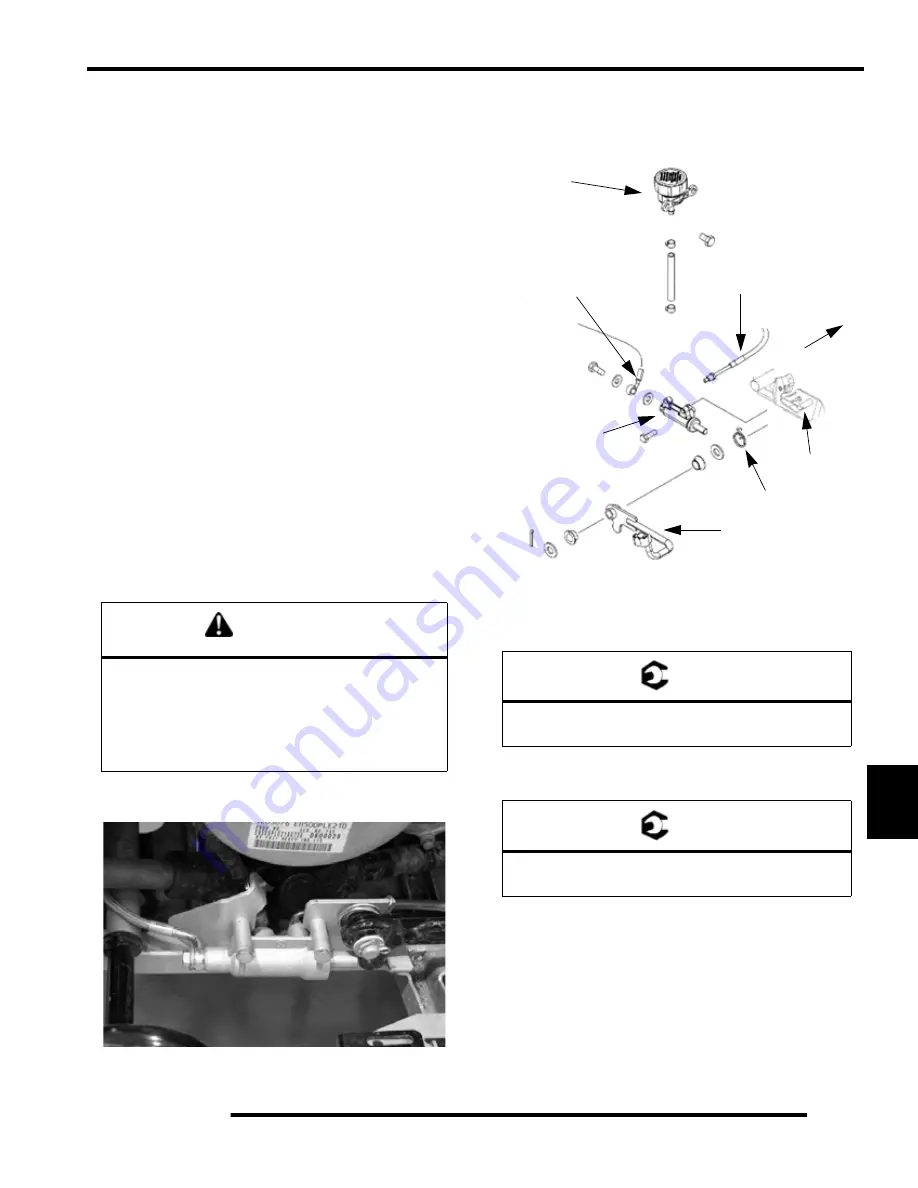

X2, Touring Rear Master Cylinder Removal

and Installation

1.

Remove the RH footwell to gain access to the rear master

cylinder.

2.

If required, remove the rear brake line from the master

cylinder. Use a suitable container to catch the brake fluid.

Dispose of brake fluid properly.

3.

Remove the two bolts that secure the rear master cylinder

to the frame. Replace parts as needed.

4.

To install the rear master cylinder, mount the master

cylinder to the frame and torque bolts to specification.

5.

Reinstall the brake line and torque the banjo bolt to

specification.

6.

Perform brake bleeding procedures as outlined in this

chapter.

CAUTION

Use only DOT-approved

brake fluid as an assembly

aid for all procedures described in this chapter to

prevent brake system contamination.

DO NOT USE LUBRICANTS OF ANY KIND FOR

ASSEMBLY, AS THEIR USE CAN CAUSE

RUBBER COMPONENTS TO SWELL.

=

T

Master Cylinder to Frame Bolt Torque:

8 ft.lbs. (11 Nm)

=

T

Banjo Bolt Torque:

15 ft.lbs. (21 Nm)

Frame

Brake Fluid Reservoir

Brake Lever

Front Brake Line

Brake Mount

Rear Brake Line

Spring

Rear Brake MC

Summary of Contents for Sportsman 800 EFI

Page 4: ...NOTES ...

Page 18: ...NOTES GENERAL INFORMATION 1 14 ...

Page 25: ...2 7 MAINTENANCE 2 LUBRICATION FLUIDS SPORTSMAN Component Locations Sportsman Only Deluxe ...

Page 56: ...2 38 MAINTENANCE Maintenance Schedule Service Date Hours Miles Service Performed Serviced By ...

Page 116: ...NOTES ENGINE 3 60 ...

Page 137: ...4 21 FUEL INJECTION 4 EFI CIRCUIT Power On EFI CIRCUIT Crank Position Sensor ...

Page 138: ...4 22 FUEL INJECTION EFI CIRCUIT Fuel Pump EFI CIRCUIT Throttle Position Sensor ...

Page 140: ...4 24 FUEL INJECTION EFI CIRCUIT Malfunction Indicator Light ...

Page 167: ...5 27 BODY STEERING SUSPENSION 5 X2 CARGO BOX Exploded View ...

Page 170: ...5 30 BODY STEERING SUSPENSION X2 SEAT ASSEMBLY Exploded Views ...

Page 174: ...NOTES BODY STEERING SUSPENSION 5 34 ...

Page 206: ...NOTES CLUTCH SYSTEM 6 32 ...

Page 244: ...7 38 FINAL DRIVE Rear Gearcase Exploded View ...

Page 245: ...TRANSMISSION 8 1 CHAPTER 8 TRANSMISSION 8 SPORTSMAN 8 3 8 18 SPORTSMAN X2 8 19 8 38 ...

Page 246: ...NOTES TRANSMISSION 8 2 ...

Page 248: ...8 4 SPORTSMAN TRANSMISSION TRANSMISSION EXPLODED VIEW Sportsman Transmission ...

Page 265: ...8 21 X2 Touring Transmission 8 242 262 262 262 262 262 ...

Page 266: ...8 22 X2 Touring Transmission Mounting Exploded View x2 x3 x4 x4 x2 x1 x1 x1 ...

Page 312: ...NOTES BRAKES 9 30 ...

Page 322: ...10 10 ELECTRICAL SPEEDOMETER TROUBLESHOOTING Test 1 No All Wheel Drive ...

Page 323: ...10 11 ELECTRICAL 10 TEST 2 No Display TEST 3 No Reverse Speed Limit ...

Page 324: ...10 12 ELECTRICAL TEST 4 No AWD Hub Safety Limiter ...

Page 325: ...10 13 ELECTRICAL 10 TEST 5 Reverse Speed Limiter TEST 6 Speed Sensor ...

Page 326: ...10 14 ELECTRICAL TEST 7 No Fuel Gauge TEST 8 Transmission Switch ...

Page 357: ...10 45 ELECTRICAL 10 BASIC WINCH WIRING PRE WIRED MODELS ...

Page 367: ...10 55 ELECTRICAL 10 Cooling Fan EFI Fuel Pump EFI ...

Page 368: ...10 56 ELECTRICAL Gear Switch EFI Power Circuit EFI ...

Page 369: ...10 57 ELECTRICAL 10 Reverse Override EFI Fan Control EFI ...

Page 370: ...10 58 ELECTRICAL Start Circuit EFI Start Enable EFI ...

Page 373: ...11 3 800 TOURING EFI INTERNATIONAL 11 Exploded View Foot Brake Supply Hand Brake Supply ...

Page 376: ...NOTES 800 TOURING EFI INTERNATIONAL 11 6 ...

Page 382: ...IX 6 Intentional Blank Page ...

Page 383: ...WD 1 WIRE DIAGRAM 2008 SPORTSMAN 800 EFI WIRE DIAGRAM ...

Page 384: ...WD 2 WIRE DIAGRAM ...

Page 385: ...WD 3 WIRE DIAGRAM 2008 SPORTSMAN 700 X2 800 TOURING EFI WIRE DIAGRAM ...

Page 386: ...WD 4 WIRE DIAGRAM ...

Page 387: ...WD 5 WIRE DIAGRAM 2008 SPORTSMAN 800 TOURING EFI INTERNATIONAL WIRE DIAGRAM ...

Page 388: ...WD 6 WIRE DIAGRAM ...