DD-75-181 R(2)

Y.T.13.07.17

14

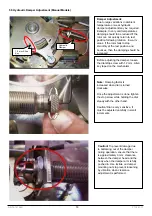

Damper Adjustment:

Due to large variations in ambient

temperature or wear hydraulic

damper adjustment may be required.

Example; In very cold temperatures

damping should to be reduced if the

rotor can not quickly return to rest

position following rotation. In warm

areas, if the rotor fails to stop

smoothly at the rest position and

bounces, then the damping should be

increased.

Before adjusting the damper, loosen

the dial stop screw with 1.2 mm. Allen

key taped on the mechanism.

5.5 Hydraulic Damper Adjustment (Manual Models)

Note:

Damping factor is

increased when dial is turned

clockwise.

Once the adjustment is done, tighten

the stop screw while holding the dial

steady with the other hand.

Caution! Dial is very sensitive. It

must be adjusted carefully in small

increments.

Caution!

To prevent damage due

to bottoming out of the damper

during operation, ensure that there

is approximately 3 mm. clearance

between the damper head and the

body when the damper arm is fully

pushed in. Use loctide on damper

mounting nuts to prevent loosening

by vibration when clearance

adjustment is performed.

1

.2 mm. Allen

Key

H

ydraulic

Damper

1.2 mm. Allen

Key

Hydraulic

Damper