DD-75-181 R(2)

Y.T.13.07.17

17

Arıza Tanımı

Olası Nedeni

Önerilen Çözüm

Turnstile fails to lock/ free

wheels following passage

Rotor gets stuck

intermittently during rotation

No response to input/reader

device. No access

No passage confirmation

contact out of control board

Turnstile free wheels in one

direction

Turnstile unlocks upon input

but motor does not run

(motorized models)

Motorized rotor keeps

moving/ fails to stop in

middle position.

Motorized rotor turns too

slow and times out/ alarm

activated.

1.

Dislocated, broken lock lever spring

2.

Solenoid failure

3.

Loose or faulty photo sensor

1.

Loose or broken ratchet spring

1.

Loose/incorrect reader connection

2.

Reader fault

3.

Faulty control board

1.

Loose connection at output terminal

2.

Faulty control board

1.

Dip switch 3, 4 might be set for free

passage (see 5.4.2)

2.

Loose solenoid connector

3.

Loose lock lever spring

4.

Jammed lock lever

1.

Loose motor/ motor driver board

connection

2.

Tripped motor driver protection circuit

breaker or blown fuse

3.

Faulty motor driver board

4.

Faulty motor

1.

Loose photo sensor connector

2.

Misaligned, bent or contaminated photo

sensor

3.

Faulty photo sensor

1.

Too low motor speed setting on motor

driver board

2.

Loose or oil contaminated drive belt

slipping

1.

Repair/ replace lock lever spring

2.

Replace solenoid.

3.

Re-connect, replace photo sensor

1.

Re-install/ replace spring

1.

Check/repair reader connections

2.

Replace faulty reader/input device

3.

Replace control board

1.

Repair connection

2.

Replace control board

1.

Set dip switches ‘off’

2.

Re-insert connector

3.

Repair lock lever spring

4.

Repair lock lever

1.

Repair/ tighten connection

2.

Do a power off reset/ replace blown

fuse

3.

Replace motor driver board

4.

Replace motor

1.

Repair/tighten photo sensor connector

2.

Adjust/ clean photo sensor

3.

Replace photo sensor

1.

Increase motor speed (turn speed

control in ccw direction) on motor driver

board

2.

Clean/ tighten drive belt

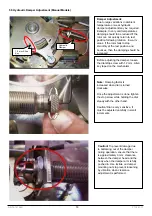

Lock lever action must be free and smooth.

Clean and apply light machine oil if lock

lever is jamming.

Photo sensors must be symmetrically aligned with

the disc slot at stop position and never in contact

with moving parts. Keep free of dust, grease etc.

LOCK LEVER MOVEMENT

PHOTOSENSOR ALIGNMENT

Description of Fault

Possible Cause

Recommended Action