DD-75-181 R(2)

Y.T.13.07.17

7

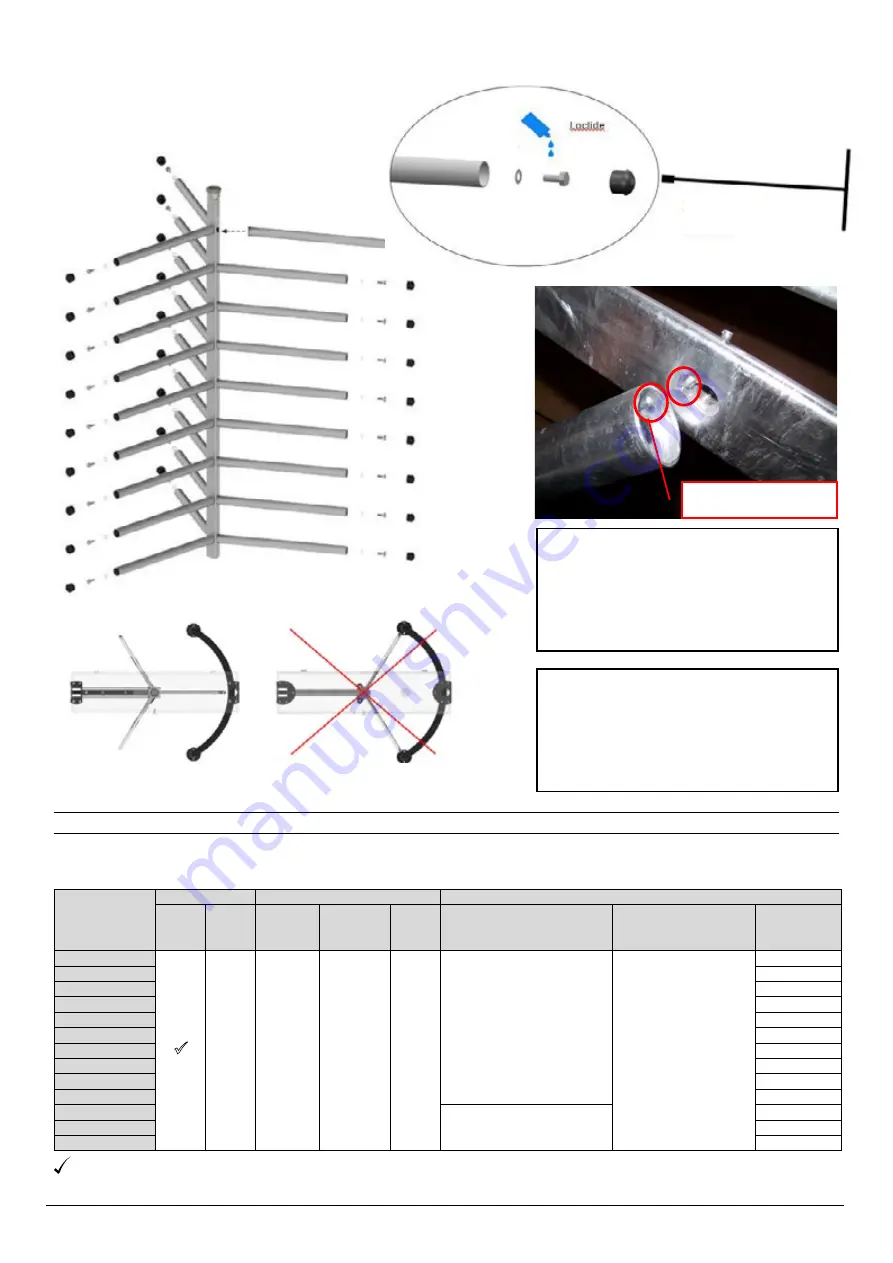

3.3 Mounting of Arms

Caution!

Arms can loosen and fall

if not mounted correctly.

Kilitleme pimleri

Attach arms on the rotor and turn counter

clockwise until lock pins are engaged to

prevent removal of the arms by turning.

Fully tighten arm bolts (apply loctide) and

install arm caps by tapping with a rubber

hammer.

Lift the mechanism channel at one end to

correctly adjust rotor position and re-seat

it on the rotor coupler. Refer to detailed

assembly instructions supplıed with each

turmstile model.

19 mm socket wrench

with long handle

Mounting of Arms

Incorrectly Installed Rotor

Correctly Installed Rotor

4. TURNSTILE SYSTEM SPECIFICATIONS

4.1 Full Height Turnstile Table of Specifications

Lock pins

Manual

Motor

Driven

Movement Lock Control

Stop

Structural Materials

Rotor

&

Arm

Arm

Configuration

BT 312 S / D

3 Arms (120

˚

)

BT 402 S / D

4 Arms (90

˚

)

BTE 312 S /D

3 Arms (120

˚

)

BTE 402 S / D

4 Arms (90

˚

)

BTX 100

1 Arm (90˚+90˚)

BTX 300 S / D

3 Arms (120

˚

)

BTX 400 S / D

4 Arms (90

˚

)

BTA 300 *

3 Arms (120

˚

)

ECOLINE 300 S / D

3 Arms (120

˚

)

ECOLINE 400 S / D

4 Arms (90

˚

)

BT 302 GL *

3 Arms (120

˚

)

BT 400 GL *

4 Arms (90

˚

)

BT 402 GL *

4 Arms (90

˚

)

MODEL

-Glass (Side Walls)

-Aluminium

-304 / 316 Grade Stainless Steel

Mechanism

Operation

Materials

H

yd

ra

u

lic

Da

mp

er

-Hot Dip Galvanized Steel

-Hot Dip Galvanized and

Electrostatic Powder Coated

Steel

-304 / 316 Grade Stainless

Steel

-Acrylic (arm,for BTA300)

9

Ο

Push to

Rotate

(Optional

Motorized)

Solenoid

Hot Dip Galvanized Steel

-Hot Dip Galvanized and

Electrostatic Powder Coated Steel

-304 / 316 Grade Stainless Steel

: Standard

Ο : Optional

* : Opt. different materials