8

ID-E339-001GB

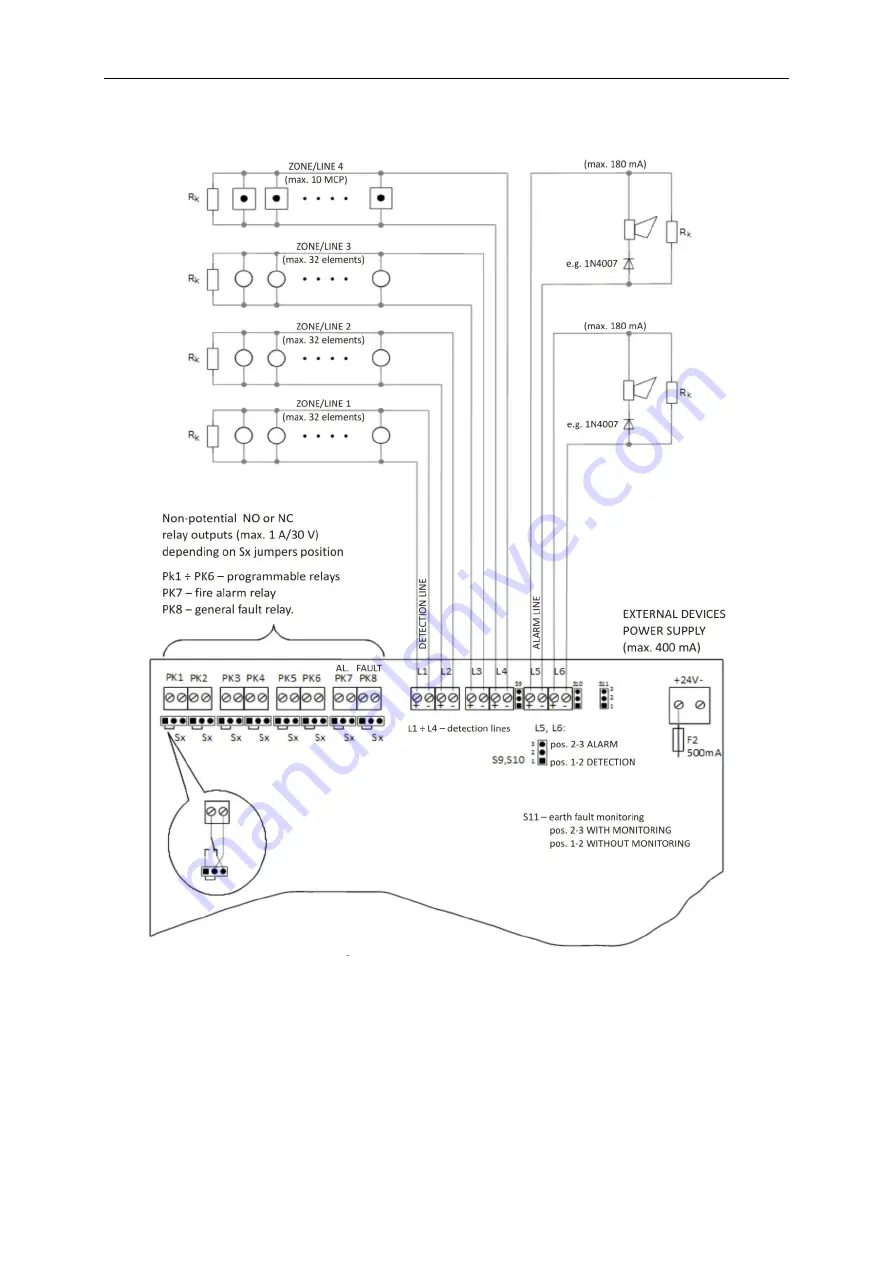

4.2 OVERALL DIAGRAM

Fig. 1 Overall diagram

4.3 CONTROL PANEL GENERAL DESCRIPTION

The control panel is intended for wall mounting. The front side is made in the form of a metal cover

plate with a rectangular window in which all handling and signalling elements are located as well as a

liquid crystal display. The cover plate can be removed after unfastening 4 screws. Cable bushings are

located in the casing upper part and they are intended to introduce alarm installation wires and

mains power supply conductors. Some space is also provided there to place spare cables. The