12

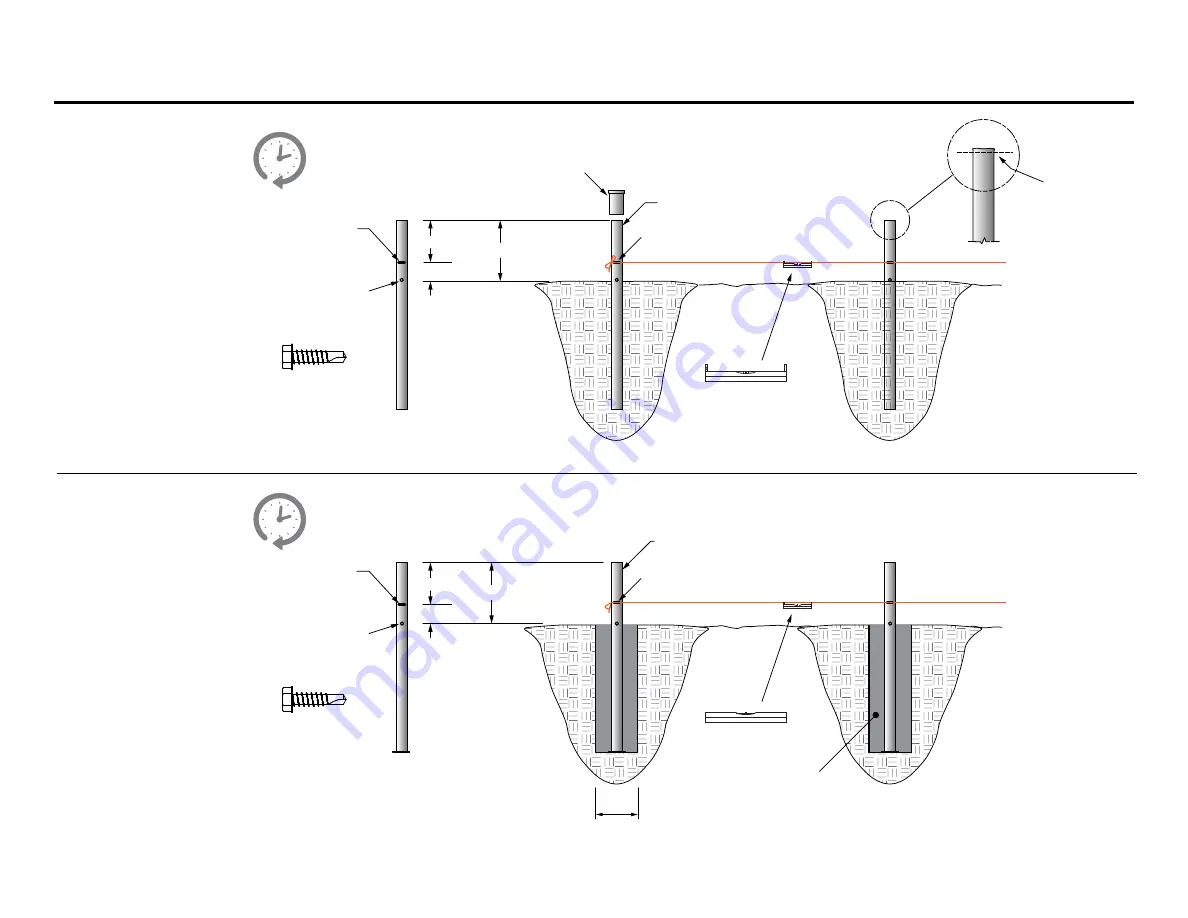

Ground Stake and Ground Stand Installation

Driving Tool

HT1000

Masons Line

Line level

4

8

12

Driven Ground Stake

Ground Stand in Compacted Soil

Ground Stake GS2404

Note:

If the top of the stake

becomes deformed

from driving in the stake,

cut off damaged

section from

top of stake.

Ground Stake GS2404 Preparation

Ground Stand GS2405 Preparation

To save time, you can

prep all the stakes

ahead of time.

To save time, you can

prep all the stakes

ahead of time.

Place a mark 8

from top of stake.

Install self-drilling

screws before driving

in the stake.

NB1809 1/4

-14 x 1

Self-Drilling Screw

4

8

12

Masons Line

Ground Stand GS2405

6

Min. hole

Compacted Fill

Ground stakes are driven

into the ground using the

Driving Tool (HT1000)

until the top of the

ground stake is 12

above

the soil line.

A masons (twisted) line is

attached between all four

corner stakes 8

from the

top of stakes. Use a line

level to line up all the

stakes at the 8

mark.

For longer structures, the

masons line may need to

be supported every 50

to prevent sagging. Sight

down the line visually to

check the straightness of

the line.

Ground stands are

placed into a 6

diameter

(min.) hole. The top of the

ground stand will be 12

above the soil line.

Ensure that the ground

stands remain plumb

while compacting the soil

all around.

A masons (twisted) line is

attached between all four

corner stakes 8

from the

top of stakes. Use a line

level to line up all the

stakes at the 8

mark.

For longer structures, the

masons line may need to

be supported every 50

to prevent sagging. Sight

down the line visually to

check the straightness of

the line.

Line level

Mark

Mark

Place a mark 8

from top of stake.

Install self-drilling

screws before driving

in the stake.

NB1809 1/4

-14 x 1

Self-Drilling Screw