1.

Entrapment Avoidance:

There shall be no protrusions or other obstruction in the swimming area, which may cause entrapment or entanglement of the user. If

a suction outlet cover is missing or broken, do not use the pool. Suction can cause body part entrapment, hair and jewelry entanglement, evisceration, or drowning.

Repair or replace the suction outlet cover before allowing the pool to be used.

2. DANGER! TO AVOID SERIOUS INJURY OR DEATH, CLOSE THE POOL OR SPA TO BATHERS IF ANY SUCTION OUTLET COVER/GRATE IS MISSING,

BROKEN, OR INOPERATIVE.

3. Never play or swim near drains or suction fittings. Your body or hair may be trapped causing permanent injury or drowning.

4. Never enter the pool or spa if a suction fitting or drain cover is loose, broken, or missing.

5. Immediately notify the pool/spa owner or operator if you find a drain cover loose, broken, or missing.

Drowning Risk

1. Keep unsupervised children from accessing the pool by installing fencing or other approved barriers around all sides of pool. State or local laws or codes may require

fencing or other approved barriers. Check state or local laws and codes before setting up pool.

2. Toys, chairs, tables, or similar objects that a young child could climb shall be at least four feet (4’) [121.92 cm] from the pool. The pump filter system shall be positioned

so as to prevent it being used as a means of access to the pool by young children. Do not leave toys inside pool when finished using, since toys and similar items

might attract a child to the pool.

3. Position furniture (for example: tables, chairs) away from pool and so that children cannot climb on it to gain access to the pool.

Electrocution Risk

1. Keep all electrical lines, radios, speakers, and other electrical appliances away from the pool.

2. Do not place pool near or under overhead electrical lines.

4

Should you encounter any problems, contact Customer Service at (888) 919-0070 from 8 AM to 5 PM Mon. thru Fri.

MST. Extended operating days and hours during peak season requirements.

6.

CAUTION:

For continued protection against possible electric shock this unit is to be mounted to the base in accordance with the installation instructions.

7. Do not bury cord. Locate cord to minimize abuse from lawn mowers, hedge trimmers, and other equipment.

8. The unit is provided with a ground-fault circuit-interrupter (GFCI). To test the GFCI, push the test button. The GFCI should interrupt power. Push the reset button.

Power should be restored. If the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to the pump without the test button being

pushed, a ground current is flowing, indicating the possibility of an electric shock. Do not use this pump. Disconnect the pump and have the problem corrected by

a qualified service representative before using.

9. The Filter Pump is to be assembled by an adult; care should be taken in the unpacking and assembly of the Filter Pump, this pool may contain accessible

potentially hazardous sharp edges or sharp points that are a necessary part of the function of the Filter Pump.

10. If a drain or suction outlet cover is missing or broken, do not use the pool. Suction can cause body part entrapment, hair and jewelry entanglement, evisceration,

or drowning. Repair or replace the drain or suction outlet cover before allowing the pool to be used.. During nighttime pool use, artificial lighting shall be used to

illuminate all safety signs, ladders, steps, deck surfaces and walks.

11. The floor of the pool shall be visible at all times from the outside perimeter of the pool.

12. Post a list of emergency telephone numbers such as the nearest available police, fire, ambulance and/or rescue unit. These numbers are to be kept near the

telephone, which is closest to the pool.

13. Basic lifesaving equipment, including one of the following should be on hand at all times:

• A light, strong, rigid pole (shepherds crook) not less than twelve feet (12’) [366 cm] long.

• A minimum one-fourth inch (1/4”) [6.35 mm] diameter rope as long as one and one half (1-1/2) times the maximum width of the pool or fifty feet (50’) [15.24 meters],

whichever is less, which has been firmly attached to a Coast Guard-approved ring buoy having an outside diameter of approximately fifteen inches (15”) [38.1 cm],

or similarly approved flotation device.

14. Pool shall be located at a minimum distance of 6 ft (1.83 m) from any receptacle, and all 125-volt 15- and 20-ampere receptacles located within 20 ft (6.0 m) of the

pool shall be protected by a ground fault circuit interrupter (GFCI), where distances are by measuring the shortest path the supply cord of an appliance connected

to the receptacle would follow, without piercing a floor, wall, ceiling, doorway with hinged or sliding door, window opening, or other effective permanent barrier, to

the inside wall of the pool.

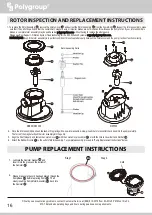

Circulation Systems

1. Installers shall follow written instructions regarding positioning of all equipment connected to the circulation systems.

2. The installer shall follow written instruction provided for operation of the circulation system components.

3. All circulation system components and pump that require replacement or servicing shall be installed according to the pump’s instruction manual.

4. Circulation equipment shall be installed per manufacturer’s instructions to provide proper mounting and support, to prevent damage from misalignment, settlement,

and vibration, and to minimize the potential for the accumulation of debris and moisture. Please refer to pump’s instruction manual.

Chemicals

For safety sake, ensure the deepest part of the pool is always visible. The user must properly maintain the clarity of the pool water at all times. Check the pH and

chlorine levels periodically and make sure they are within the recommended limits. Additional water treatment chemicals might be needed from time to time. Have

the water sample tested by a local pool supply store to determine if additional chemical is needed. Turn on the pump for the recommended hours daily. If you are

unsure of the time frames please refer to support.polygroupstore.com for the recommended Pump Operation Hours based on pool types and sizes. Clean and

replace filter cartridge frequently. Replace only with genuine Polygroup

®

/ Summer Wave

®

Brand filter cartridge. Refer to the Filter Pump manual for

additional water care information.

Entrapment Risk

Summary of Contents for SUMMER WAVES RX1000

Page 20: ......