18

19

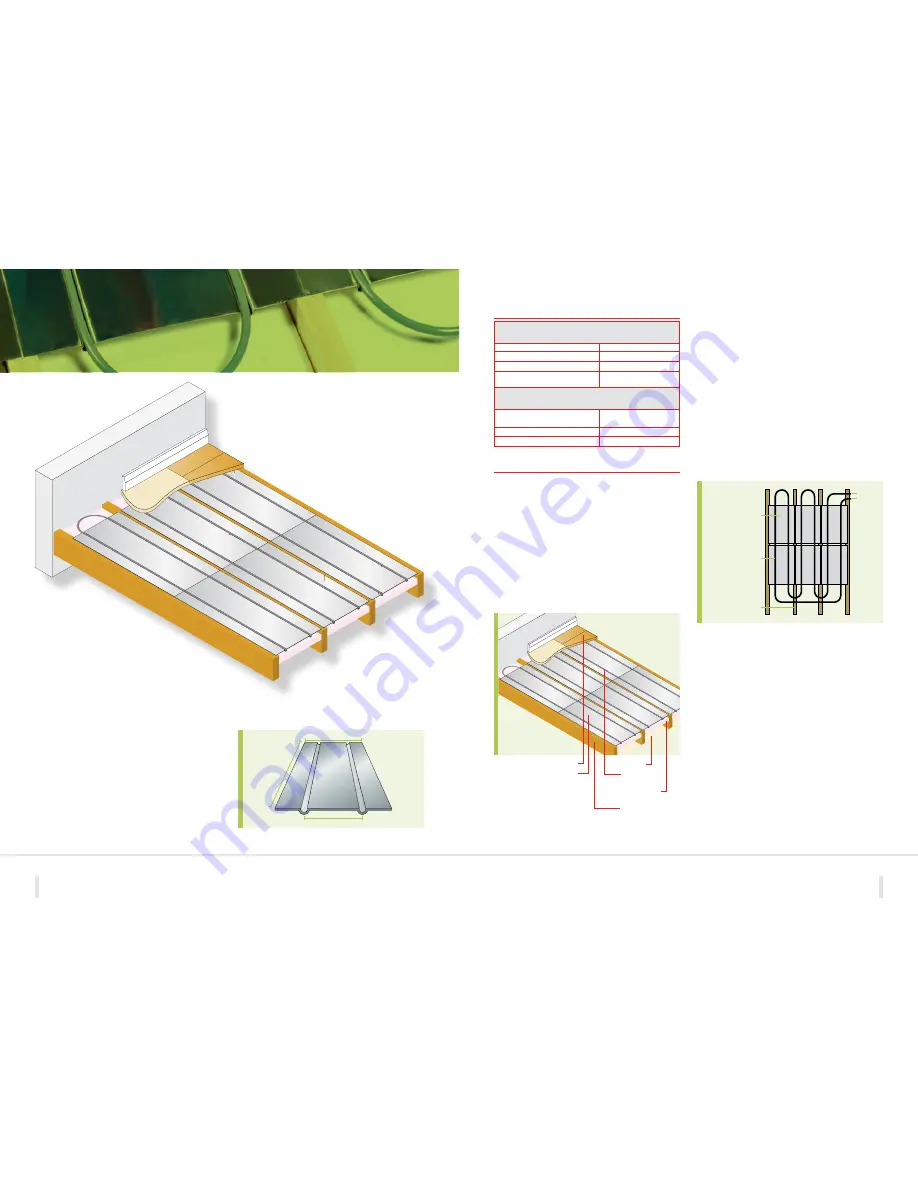

SUSPENDED FLOOR

Pre-installation requirements

Installation

Fitting nsulation

Step 1:

Before installing a suspended floor system it is necessary to insulate

between the joists. Polypipe recommend that a rigid polystyrene

or foam insulation material is used.

Fitting the spreader plates

Step 2:

The insulation layer should fit tightly between the joists directly

below the spreader plate to ensure that the spreader plate is

supported and therefore remains in contact with the underside

of timber floor covering. This is necessary to eliminate any air

gaps or draughts between the under floor heating system and

the floor.

Any other services, such as drainage or electrical wiring, should be

installed below the insulation layer.

The floor joists then need to be notched or drilled in accordance

with Building Regulations. This facilitates the passage of the pipe

between the joist gap to allow the entry and exit of the pipe

to and from the room.

The spreader plates can then be fixed evenly across the joists and

in accordance with your installation design.

Laying the pipe

Step 3:

Once the spreader plates have been fixed in place the pipe can

be fitted in to the grooves in a meander pattern. It is recommended

that the flow pipe from the manifold be taken to the furthest point

of the room when installing the circuit as this ensures that sufficient

heat is provided around the perimeters of the room.

Care should be taken when installing the pipe to ensure the

spreader plates are not pushed downwards and away from the

underside of the timber finished floor covering as this could lead to

potential underperformance of the system.

Testing

Step 4:

Once the pipe circuits have been installed and connected to

the manifold the system should be pressure tested to 6 bar for

a minimum of 1 hour before the timber floor covering is laid.

It is recommended that the system remains under pressure whilst

the flooring is laid.

Double heat

spreader plate

Pipe

Return

Flow

Joists notched to

accept pipe returns

Designed for use in timber suspended or battened floors the Polypipe suspended

floor system uses aluminium double heat spreader plates to transmit the heat

evenly across the finished floor surface.

Suitable for joist widths of 300mm to 450mm the spreader

plates are simply fixed to the joist using small nails or staples.

The pipe is then run in to the preformed grooves of the

panels which are designed to hold the pipe securely at

225mm average centers.

A layer of insulation below the panels will ensure that almost

all of the heat generated passes up in to the room.

The Polypipe suspended floor system is also suitable for use

with ‘sprung’ flooring systems as used in sports halls, etc.

Key design and installation information

Material requirements (approx)

Maximum heat output

Approx.

70W/m

2

Recommended design flow temp

60°C

Maximum circuit length

80m (15mm pipe)

Maximum coverage per circuit

17m

2

at 225mm average

double heat spreader plates (15mm)

centres

Double heat

spreader plates

Pipe

4.5m/m

2

Heat spreader plates

2 plates/m

2

Ceiling

Polyplumb

barrier pipe

Polystyrene

or foam insulation

Supporting joists

Tongue & groove flooring

Double heat

spreader plate

450mm

1000mm

250mm