20

21

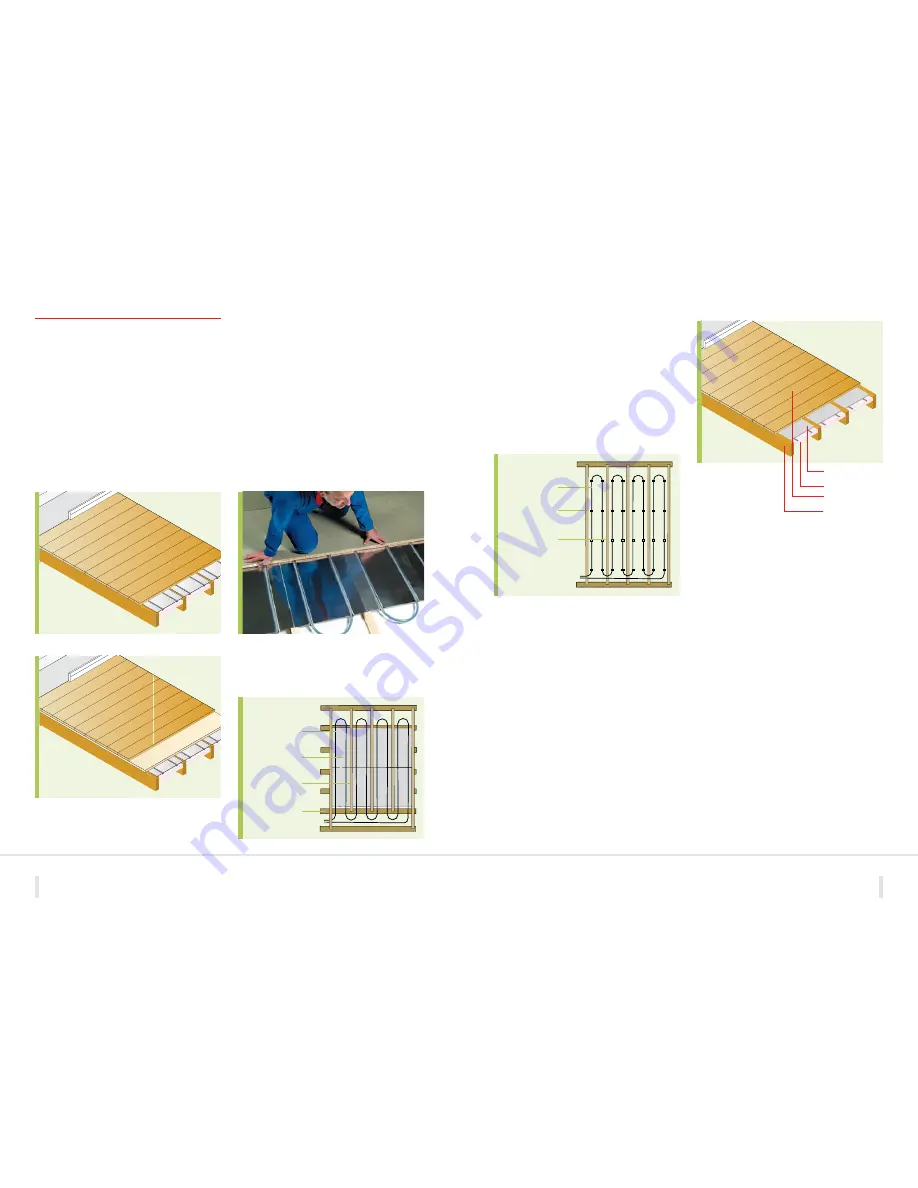

Pipe only systems

The use of heat spreader plates is recommended, as they assist the

response time and heat dispersion. However, in some circumstances,

simply laying pipe in an air void between foil faced reflective

insulation and the underside of the floorboard will be adequate.

The space between the top of the insulation and the underside

of the floor deck should be kept to a minimum (20mm) and care

should be taken to ensure that the insulation is sealed at the

edges and ends.

Pipe only applications are suitable in areas where the heating response

is less important, e.g. bedrooms, and is not recommended in living

spaces or over unheated spaces, e.g. rooms above garages.

Enhancing pipe only systems

The effectiveness of pipe only systems can be enhanced by laying

a weak (1:6) dry mix screed approximately 25mm thick between

the joists.

In order to apply this, extra support may be required below the

insulation. Although pipe only systems are designed to operate

at 60°C flow temperature, the flow temperature may be reduced

in these circumstances.

Before this system is considered it is suggested you consult

a structural engineer to confirm its suitability.

Finishing

Laying a timber floor covering

Step 5:

It is strongly recommended that the timber floor covering is laid

immediately after the under floor heating pipes have been installed

and pressure tested to eliminate any risk of damage to the system

by other trades.

Either traditional tongue & groove floorboards or 18mm/22mm

chipboard can be fitted directly on top of the spreader plates.

These can be fixed directly through the spreader plate down in to

the joists below. It is important to indicate the position of pipework

in areas where the additional fixing of items such as carpet grip rod

or door threshold strips may be fitted at a future date.

Polypipe does not recommend the application of two layers of

timber floor covering as this will severely reduce the heat output of

the under floor heating system.

Correct application

Incorrect application

If a manufactured timber floor is to be used then it is recommended

that this be of a suitable load bearing quality. (Please request advice

from the specialist flooring supplier).

Battern systems

Used for spans greater than 450mm or less than 350mm.

Where it is not possible or desirable to drill or notch the floor joists,

and the floor height can be raised, spreader plates can be used.

Fitting insulation with a battern system

Step 1:

To prevent downward heat transmission, insulate between the

voids in the joists with appropriate foam insulation.

Fitting the batterns

Step 2:

Lay 75mm x 25mm battens across the existing joists at 450mm centres.

Trim the ends of the batten back to the last joist at alternative ends.

Fitting the spreader plates

Step 3:

Lay spreader plates between the battens and pin in position.

Laying the pipe

Step 4:

Lay pipe into the spreader plates in accordance with the installation

instructions on the previous page, ensuring you follow the

testing procedure.

Joists at spacing

greater than

450mm or less

than 350mm

Polyplumb

barrier pipe

Pipe clip

75mm x 25mm

battens at

450mm centres

Polyplumb

barrier pipe

Double heat

spreader plate

Joists at spacing

greater than 450mm

or less than 350mm

25mm thick dry

mix screed

Insulation

Tongue and

groove flooring

Joists