38

39

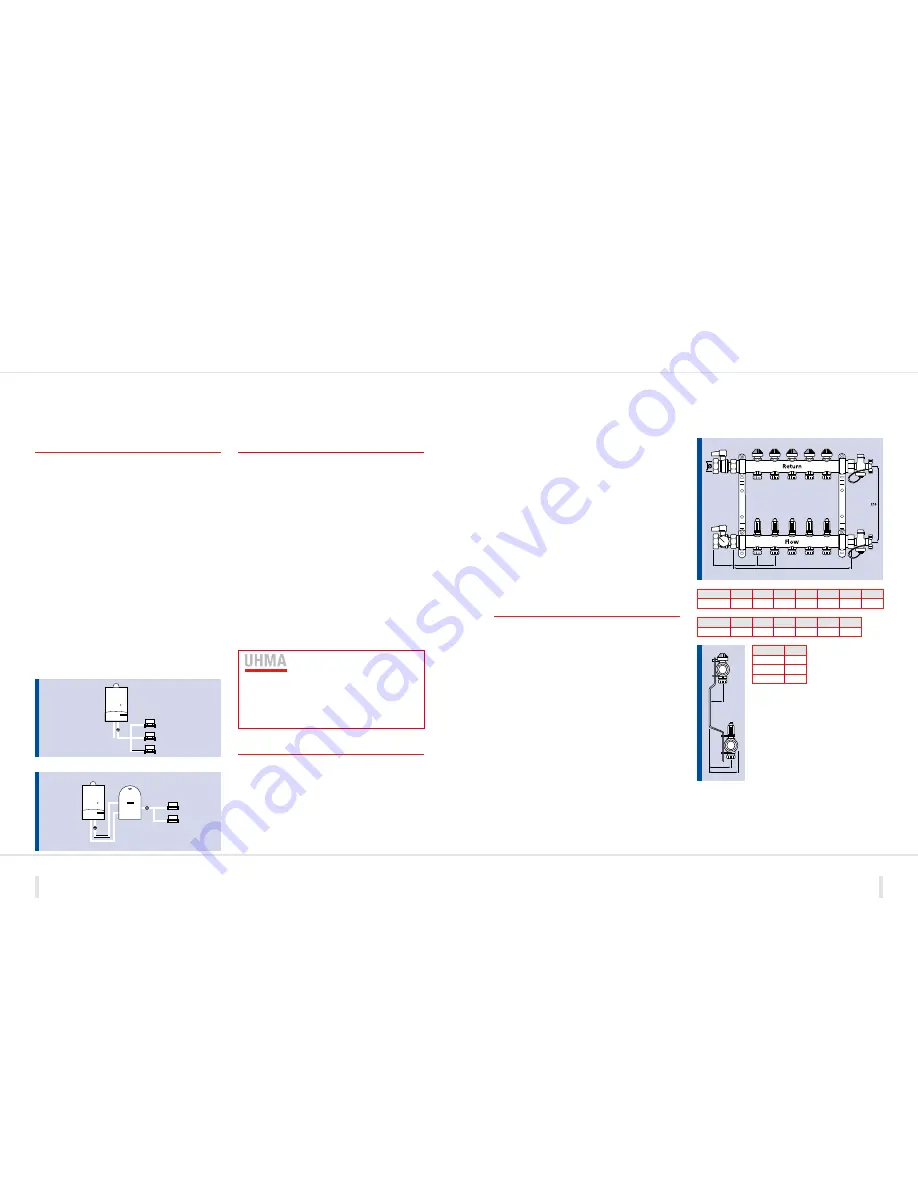

MANIFOLDS

Manifolds are common to all systems above 30m

2

, independent of the under floor heating

system. Manifolds are supplied complete and fixed to the wall mounting bracket.

The manifold comes complete with a drain and air vent assembly,

which can be positioned on either end of the manifold. Isolation

valves are supplied separately for the supply end of each manifold.

The bottom manifold is the flow and the top manifold is the

return. Each manifold port comes complete with a Polyplumb

push fit connection. Pipes are connected to manifolds by

inserting a pipe stiffener into the pipe and simply push fitting

the pipe into the port.

The flow meter on each flow port of the manifold provides

a visual indication of the flow through each circuit.

Both manual and lockshield balancing can be undertaken

by either using the blue cap on the return manifold for manual

adjustment, or removing the blue cap and adjusting using the

key supplied with each manifold.

Preparing and installing

the manifold

Remove the manifold from the box and arrange the flow and

return manifolds to ensure that the inlets/outlets are pointing

downwards. Remove the air vent and drain valve from the

packaging and connect to the desired end of the manifold.

Ensure the seal is correctly in place before tightening the

compression nut by hand on to the manifold. To ensure

the valves are securely connected to the manifold, use a

38mm spanner or wrench to tighten by a further half turn.

Remove the isolating valves (supplied separately) from the packaging

and connect to the opposite end of the manifold. As with

the air vent and drain valve, ensure the seal is correctly in

place before tightening the compression nut by hand on to

the manifold. Then, complete the connection by using a 38mm

spanner or wrench to tighten by a further half turn.

Fix the manifold horizontally in the desired position utilising

both screw holes on each bracket.

The manifold is now in position and ready to be connected

to the mains from the boiler and the under floor heating pipe

circuits. A set of self adhesive stickers are included to help

identify each circuit on the manifold. The stickers also provide

the opportunity to record the number of turns required for the

correct flow rate through each circuit (for further information

on testing and commissioning see pages 46 and 47).

62

L

80

50

A

B

C

Outlets

2

3

4

5

6

7

8

L (mm)

190

245

300

355

410

465

520

Outlets

9

10

11

12

13

14

L (mm)

575

630

685

740

795

850

Dimension

1”

A (mm)

39

B (mm)

64

C (mm)

86

CONNECTING TO HEAT SOURCE

Polypipe under floor heating systems are designed to be connected to a variety

of heat source options.

Gas and oil boilers

When connecting to any heat source it is essential that the under

floor heating manifold(s) are fed directly from the heat source with

a dedicated set of flow and return primaries, to enable total

independent hydraulic control of the under floor heating system.

Under no circumstances should this primary feed be connected

into any other heating pipework, such as radiator or domestic

hot water primary circuits.

To provide independent hydraulic control of the entire system, it is

important that the installation is designed as an ‘S Plan’ or ‘S Plan Plus’

configuration which allows for a two port zone valve to be fitted to all

primary circuits and at each under floor heating manifold (see diagram).

IMPORTANT NOTE:

Under no circumstances should a Polypipe

under floor heating system be connected in to a ‘Y Plan’ (flow share)

system as this will result in serious system operating problems.

To ensure that the correct operating temperatures and system flow

rates are maintained for the under floor heating system, the manifold(s)

should be fitted with a manual blending valve and circulating pump

(see section ‘Water temperature controls’). However, it is the

responsibility of the designer/installer to ensure that the boiler and

system pump are capable of providing sufficient outputs in order

to meet the requirements of the primary pipework, the under floor

heating system and any other equipment installed in the system.

Typical ‘S Plan Plus’ configuration

Typical ‘S Plan Plus’ configuration via thermal store

Heat pumps

Polypipe under floor heating systems are ideal for use with heat

pump systems due to the lower operating temperatures that

are produced by this type of heat source. However, to provide

temperature limitation protection and sufficient system flow

rate for the under floor heating installation, it is recommended

to fit the manual blending valve and pump pack as supplied

by Polypipe Building Products Ltd.

It is the responsibility of the system design/installer to ensure that

the heating circulation pump supplied with the heat pump,

and any associated primary pipework, is capable of providing

sufficient duty to meet the demand up to the under floor heating

manifold assembly. This also applies if a ‘buffer tank’ has been

fitted to the heat pump installation.

A buffer tank or thermal store is often fitted between the heat

pump and the under floor heating system. This is to provide

a sufficient quantity of stored water to feed the under floor heating

system and to ensure that the heat pump flow rates are maintained,

thereby reducing the risk of cycling. By using a buffer tank

installation there is no need to use ‘open circuits’ at the under

floor heating manifold, therefore allowing individual room control.

The Underfloor Heating Manufacturers

Association (UHMA) do not recommended

that the under floor heating system be used

as an ‘open circuit’, to provide the flow rate requirement for

the heat pump installation, as this could lead to problems

with system control at a later date. For further information

regarding the installation of the system please contact the

Polypipe Technical Hotline on

01709 770000

.

Solid fuel and wood burners

Under no circumstances should a Polypipe under floor heating

system be connected directly to this type of heat source.

Instead, the burner should be used to provide indirect heat via

a thermal store or similar neutraliser. The low temperature feed

from this store can then be pumped to the under floor heating

manifold, as with a heat pump installation.

Please seek specialist advice from the heat source supplier

or manufacturer before commencing the installation.