40

41

ROOM TEMPERATURE CONTROL

Controlling under floor heating

The control of under floor heating systems is different to that

of conventional radiator systems, as the space should not

be allowed to cool completely during the heating season.

The temperature during unoccupied or night time periods

should fall to around 4°C lower than the occupied temperature.

This lower temperature setting is known as the set-back

temperature, e.g. occupied temperature 21°C, set-back

temperature 17°C.

Individual room control

Polypipe under floor heating controls allow each room to

be both time and temperature controlled via the use of a

programmable room thermostat. Each thermostat is wired

back to a master wiring centre and slave unit, which in turns

operates the relevant manifold actuator/s, the under floor

heating pump, and the two-port zone valve. The master wiring

centre is also capable of providing either a 230V or a Volt free

switched live supply to signal the boiler.

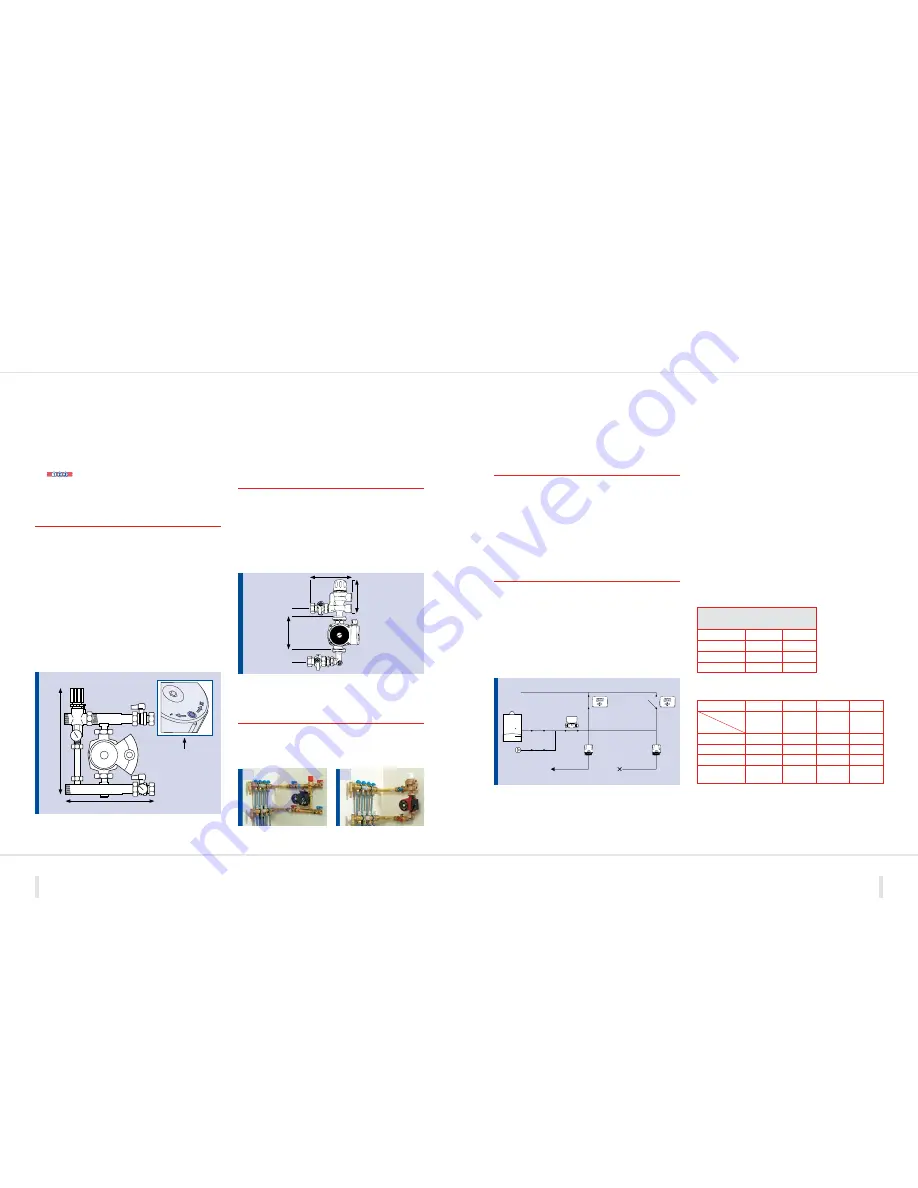

Schematic switching diagram - relays not shown

As individual rooms reach their set point temperature or when

the system is operating in ‘set back’ mode the master wiring

centre will de-energise the pump and zone valve and the signal

to the boiler will be cut, ensuring that maximum comfort levels

and system efficiencies are achieved and maintained at all times.

The number of control zones you require will depend on the

number of rooms you wish to control individually. The 4, 6 and

8 zone packs describe the number of areas you wish to control,

not necessarily the number of circuits you are supplying from

that manifold. To optimise the use of each control pack you will

need to understand the following guidelines:

• The 4 zone pack contains 4 room thermostats; the 6 zone

pack contains 6 room thermostats; and the 8 zone pack

contains 8 room thermostats

• Each room thermostat can control 1 zone and

up to 4 actuators

• Rooms over 40m

2

should be allocated as 2 zones

and have 2 room thermostats

• An actuator is required on each circuit that requires control

The room thermostats (PBPRP) and wiring centres are available

as individual items or packs, as detailed below:

A comprehensive range of room temperature control products are available

to complement Polypipe under floor heating systems. Designed specifically to

maximise both comfort and efficiency, the unique programming functions provide

the perfect control solution for under floor heating systems.

WATER TEMPERATURE CONTROLS

The temperature of water required in under floor heating systems is less than

that required for radiators or stored hot water. If these other services are

connected to the same boiler it will be necessary to control the water

temperature using one of the Polypipe water temperature control units.

All Polypipe under floor heating system packs supplied through

the selection process will contain all the appropriate

control products.

Modulating pump unit

(PB970014)

The modulating pump unit controls water temperatures between

45°C and 60°C. The inclusion of a modulating pump ensures

that the flow to the under floor heating circuits is automatically

adjusted to allow for the opening and closing of actuators

when individual room temperature is required. The unit is

suitable for manifolds demanding up to 15kW heat load.

The temperature of the water is set using the pilot pin on the

hand wheel. When the pilot pin is flush with the hand wheel

the temperature is set to 55°C. Each click to + or – increases

or decreases the temperature by 1°C.

The modulating pump unit is fitted directly to the manifold at

either end by turning the pump through 180°. An additional

zone valve is required when using a modulating pump unit

supplied by other manufacturers.

Floor heating control pack

(PB970015)

The pack controls water temperatures between 35°C and 60°C,

and incorporates a fixed head pump and a 22mm 2-port zone

valve, which is suitable for manifolds demanding up to 15kW heat

load. The set temperature of the water is shown on the wheel head.

The control pack is fitted directly to the manifold at either end,

as both left hand and right hand connector bends are supplied

with the unit.

Dimensions of assembled unit

NOTE:

The valves shown on this diagram are purchased

separately and not supplied with the unit.

Manifold bends (PB12735)

The water temperature control packs can be fitted at 90° to

the manifold using the manifold bends. This allows manifolds

and pump units to be corner mounted where space is at a

premium, e.g. in an understairs cupboard.

A)

Manifold bend installed with modulating pump unit

B)

Manifold bend installed with floor heating control pack

A)

B)

290mm

Pilot pin flush

to handwheel

260mm

155mm

110mm

50mm

30mm

130mm

40mm

Product

Class Rating IP Rating

PBPRP

Class 2

IP30

PBPRP RF

Class 2

IP30

PBTSP

Class 2

IP20

Electrical protection index

Actuator

room 2

closed

Actuator

room 1

open

Room

thermostat

room 2

satisfied

Room

thermostat

room 1

demand

Zone

valve open

Circuit

room 1 open

Circuit

room 2 closed

Boiler

on

UFH Pump

on

Pack

Single Zone 4 Zone

6 Zone

8 Zone

PB1ZP

PB4ZP

PB6ZP

PB8ZP

1 Zone Master

1

1

1

1

4 Zone Slave

1

2

6 Zone Slave

1

Programmable

Room Thermostat

1

4

6

8

Pack

Code

Content