42

43

Programmable room

thermostats

Programmable Room Thermostat PBPRP:

The PBPRP remote programmable room thermostat is a battery

operated unit and offers the following outstanding features:

• 24 hour / 7 day time and temperature control

• Optimised system start

• Set-back temperature setting

• Frost protection facility

• Holiday standby function

• Five pre-set programmes for ease of set up

• Battery low indicator

• Standard battery replacement 3 x AA LR06 1.5v (two year life)

• No loss of memory when battery change is carried out

• Wet room sensor connection provided

Wet Room Sensor PB23020:

Where time and temperature control needs to be applied to

a bathroom or wet area, the wet area sensor can be installed

within the wet room and connected to the programmable room

thermostat installed in an adjacent dry area.

The sensor is supplied with 3m of cable and can either remain in

the supplied housing and be wall mounted, or removed from the

housing and used as a floor surface sensor.

If required, the wet room sensor cable can be extended to

a maximum of 10m providing that a cable of a similar rating

is used (NTC 10k).

All Polypipe under floor heating system packs supplied through

the selection process will contain all the appropriate

control products.

Programmable Room Thermostat PBPRPRF (radio frequency):

As PBPRP unit but with the following additional features:

• Full RF operation

• Each programmer supplied with a receiver unit

• Remote thermostat has built in stand for ease of positioning

• Blue LED backlight

Touch Screen Programmable Room Thermostat PBTSP:

The PBTSP incorporates the latest touch screen technology and

is fully compatible with the master wiring centre and slave units.

Available in two surface finishes, and offers the following features:

• Large touch screen display with high visibility blue LED backlight

• On screen display shows current status and programme setting

• Programme options for 7 day, 5+2 days and working

week/weekend modes

• Allows for three separate temperatures settings per day;

- Comfort

- Economy

- Night

• Holiday standby function

• Frost protection

• Battery operated using 2 x AA LR06 1.5V (two year life)

• Available in either white (PBTSPW) or silver (PBTSPS)

Please note that the PBTSP is not compatible with the Polypipe

wet room sensor (PB23020).

Wiring centres

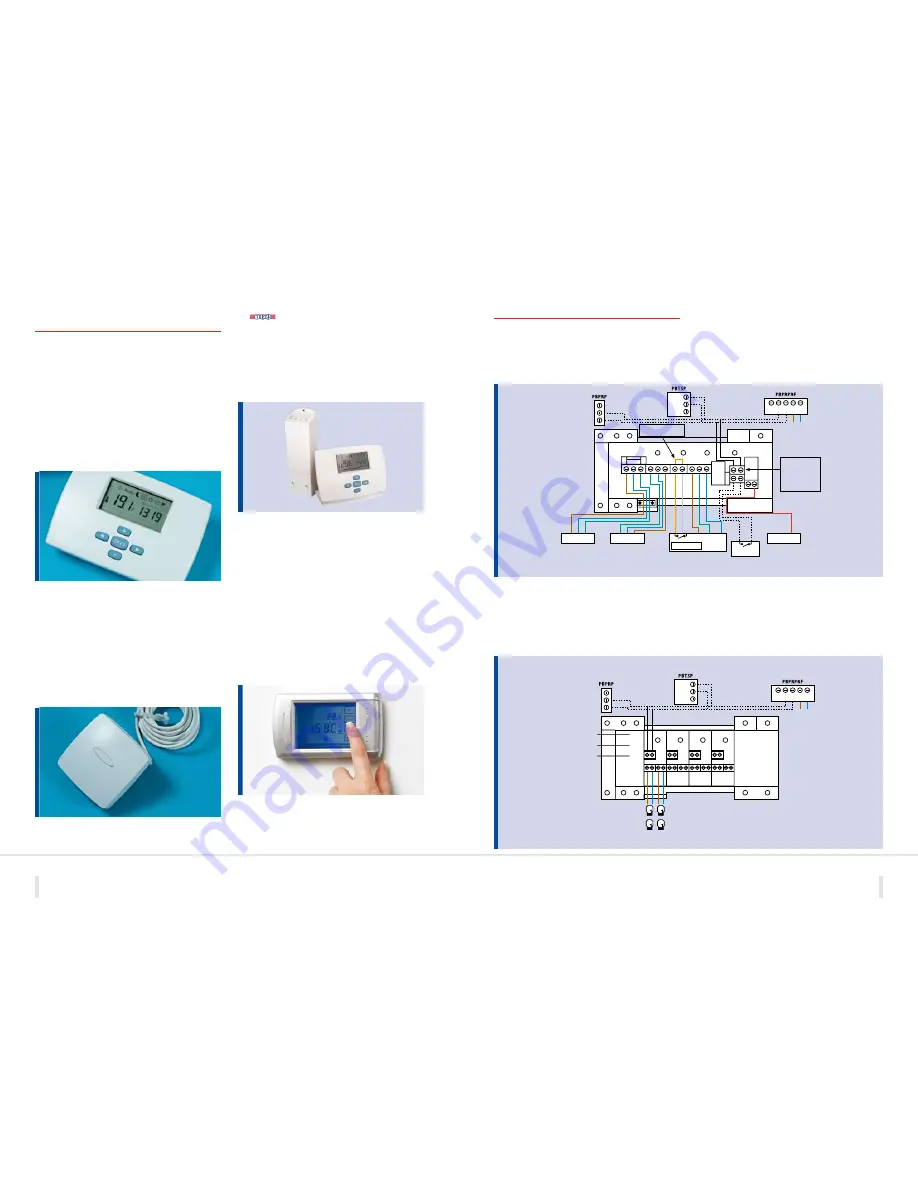

Single zone master (PB1ZM):

When used in a ‘single zone’ application the master wiring centre

(PB1ZM) provides the wiring connections for the under floor heating

pump, two-port zone valve, boiler switched live connection

(230V or volt free) and the programmable room thermostat.

Wiring details for single zone master unit (PB1ZM)

4 & 6 zone slave unit (PB4ZS & PB6ZS):

Where multiple room control is required the master wiring centre

should be used in conjunction with the 4 or 6 zone slave units

PB4ZS or PB6ZS. The slave units provide wiring connections for

the programmable room thermostats and the manifold 2-wire

actuators. Up to 4 actuators can be connected per zone.

Wiring details for 4 zone and 6 zone slave (PB4ZS and PB6ZS)

Note:

Only use this

connection when

using a Single

Room Thermostat.

If using Slave do

NOT use.

230v

Supply

OR

OR

Polypipe

Room Stat

Options

Remove Link if

Zone Valve Fitted

Power Supply

UFH Pump

2 Port Zone Valve

Volt Free

Contact

Boiler

230v S/L

Connection

Boiler

NO

COM

NC

L N E

E N L

End Switch

L

N

E

L

NC

C 1 L N

230v

Supply

OR

OR

Polypipe

Room Stat

Options

C 1 L N

NO

COM

NC

Up to 4

Actuators

per zone

2 Wire

Actuators

PB00401

Note:

1 Zone shown only -

Repeat for further Zones

Must be used with Master Unit