50

51

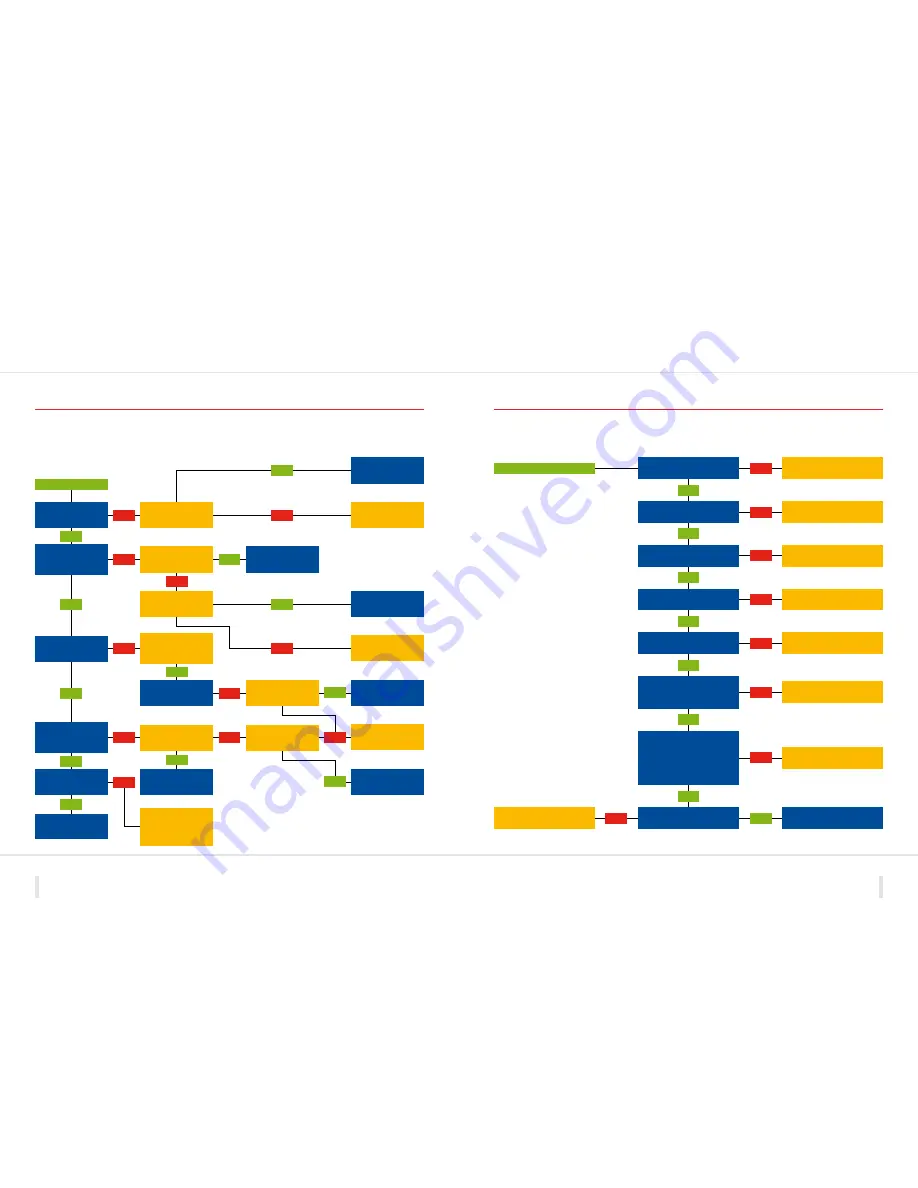

FAULT FINDING CHARTS

Before using this flow chart please ensure that both the primary and under floor

heating systems are full and that all isolating valves are fully open. Please also

ensure that the room thermostats are calling for heat.

Hydraulic fault finding chart

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

Is the fused spur

switched on?

Is there 230V at

‘L’ terminal on PCB?

Is Green Power

LED illuminated?

Is 230V present on

all T2 terminals?

Is 230V present on

all T1 terminals?

Are the zone valve

and under floor heating pump

operating?

Is there 230V to NC Boiler

switch live connection?

(Check operation

of Volt free relay

connections if using 24V)

Is the boiler firing?

Check boiler connection

Turn the fused spur on

Replace 3A fuse in spur

Replace fuse on PCB

(2.5A 230 Vac Type 5x20)

Faulty PCB -

replace unit

Faulty room thermostat -

replace unit

Relay 1 faulty replace PCB

Relay 2 faulty replace PCB

System operating correctly

Electrical fault finding chart (master connecting box)

This testing procedure should only be carried out by fully qualified persons.

Testing should be done with all switches on and room thermostats calling.

Fault finding

complete

Adjust pump speed

and set flow rates

in accordance with

the system design

data as provided

NO

NO

Is the boiler firing

and the primary

pump operating?

Check for 230V signal

to boiler from master

wiring centre

YES

NO

Is there hot water

present prior to

under floor heating

mixing valve?

Check if the under

floor heating zone

valve is open

Electrical fault

(see electrical fault

finding guide)

Boiler fault

Primary flow and

return crossed or

debris in mixing valve

YES

Check 230V signal

to zone valve from

master wiring centre

NO

NO

Under floor

heating pump

operating

Check 230V signal to

pump from master

wiring centre

NO

Is the system

performing

correctly?

Ensure that manifold

lockshield valves are

fully open

YES

START

YES

YES

YES

YES

YES

YES

NO

NO

NO

Is hot water passing

through under floor

heating manifold?

Check temperature

adjustment on

under floor heating

mixing valve

YES

YES

NO

NO

Is there a visible flow

present through

all under floor

heating circuits?

Check if the

actuators are open

Electrical fault

(see electrical

fault finding

Pump fault

Zone valve fault

Electrical fault

(see electrical fault

finding guide)

Actuator fault

Check 230V

signal to actuator

from slave unit

YES

START