OVERLAY™

LITE

OVERLAY™

SOLID

FLOOR

FLOATING

FLOOR

06

07

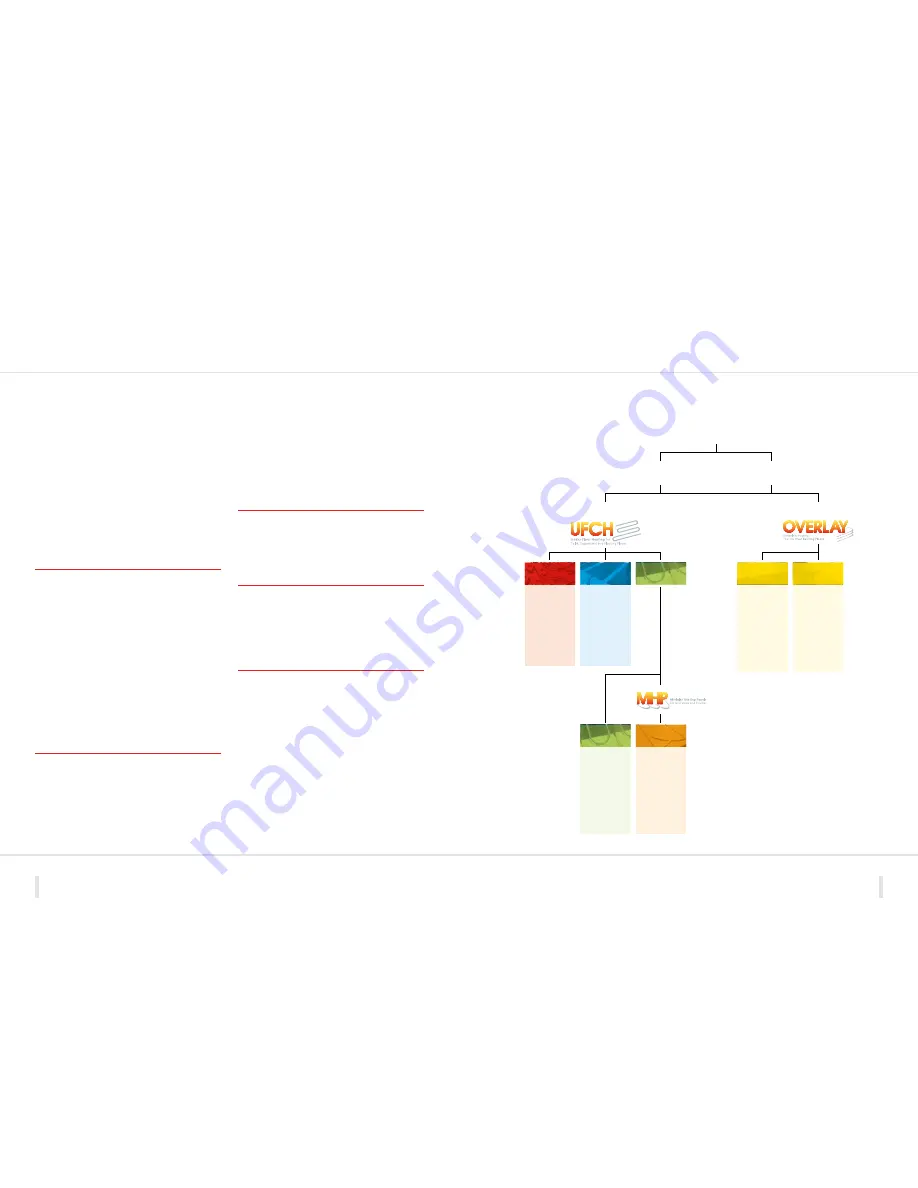

AN OVERVIEW OF UNDER FLOOR

HEATING SYSTEMS

SELECTING THE RIGHT POLYPIPE

UNDER FLOOR HEATING SYSTEM

Polypipe has the widest available range of under floor heating systems, with a

product available for every conceivable floor type or residential heating project.

With Polypipe, under floor heating is not restricted to new build developments or

self build projects. Our unique Overlay™ product is particularly well suited to single

room projects such as kitchens, bathrooms, conservatories, extensions and loft

conversions. Polypipe Modular Heating Panels (MHP) were developed to provide an

innovative and practical solution to installing under floor heating into upper floors.

The notes below provide a brief overview of the methodologies

employed to install under floor heating systems for various floor

types. Refer to the overview on the page opposite. Full installation

instructions for each floor type can be found in the section titled

‘Installing the system’ on pages 12 to 36.

Solid Floor

Polypipe under floor heating can be permanently built into solid

concrete or screeded floors. As required by current Building

Regulations, insulation is built into the floor directly beneath the

unique Polypipe lightweight plastic floor panel. The heating pipe

is simply slotted into the panel and then permanently covered by

the screed. Suitable for all floor coverings, solid floor systems can

incorporate 15mm or 18mm pipe.

The floor panels form a simple grid for the quickest possible

pipe laying and provide a precise guide to achieve the minimum

bending radius. Panel castellations are set at exact centres and

hold the pipe against movement when screeding. The floor panel

holds the pipe above the insulation allowing full screed surround.

Optimum screed depth is 65mm from the panel base, i.e. 40mm

from the pipe top. Insulation below and at the edges of the floor

screed is required by Building Regulations. Edge insulation also

acts as an expansion joint.

Floating Floor

When installed in floating floors, Polyplumb pipe is simply pressed

in to the pre-formed heat spreader plate, which sits in grooves

within the floating floor insulation panel. The floating floor

system is then covered with 18mm chipboard sheeting. Suitable

for all floor covering, floating floor systems can incorporate

15mm or 18mm pipe.

Suspended Floor

For installations in suspended floors, Polypipe under floor heating

uses double heat spreader plates. Alternatively, pipes can be laid

on top of insulation between joists. Standard tongue and groove

floorboards are laid on top of the system. Suspended double heat

spreader plate systems use 15mm pipe.

MHP (Modular Heating Panels)

Modular Heating Panels offer a revolutionary new way to solve

the issue of installing under floor heating into upper floors. MHP

is available in two widths and two lengths to fit all standard joist

spacings. All components and circuitry is pre-configured into

the panels which are simply installed between the joists, linked

together and connected to the manifold.

Overlay™

Overlay™ allows under floor heating to be installed into existing

spaces quickly, easily and practically. The unique system is

supplied with a choice of patented low profile panels to suit all

types of floor coverings. The Overlay™ system is laid over existing

solid or timber floors.

Under floor heating systems

Product selection: Typical applications and features

New build

Existing floor

SUSPENDED

FLOOR

Under floor

All floor

coverings

High mass

system

Typical ground

floor or beam

and block

construction

All floor

covering

except natural

wood/thick

laminates

Lightweight

construction

No wet trades

required

Lightweight

floor coverings

Larger areas

Multiple rooms

Tiles or

natural wood

Wet areas

Over floor

MODULAR

HEATING

PANEL

All floor

covering

Fit from above

Traditional

joists

Traditional

heat source

All floor

coverings

Fit from

above/below

Traditional

or engineered

joists

Traditional or

renewable heat

sources

SUSPENDED

FLOOR