2.6

Filling the Reservoir

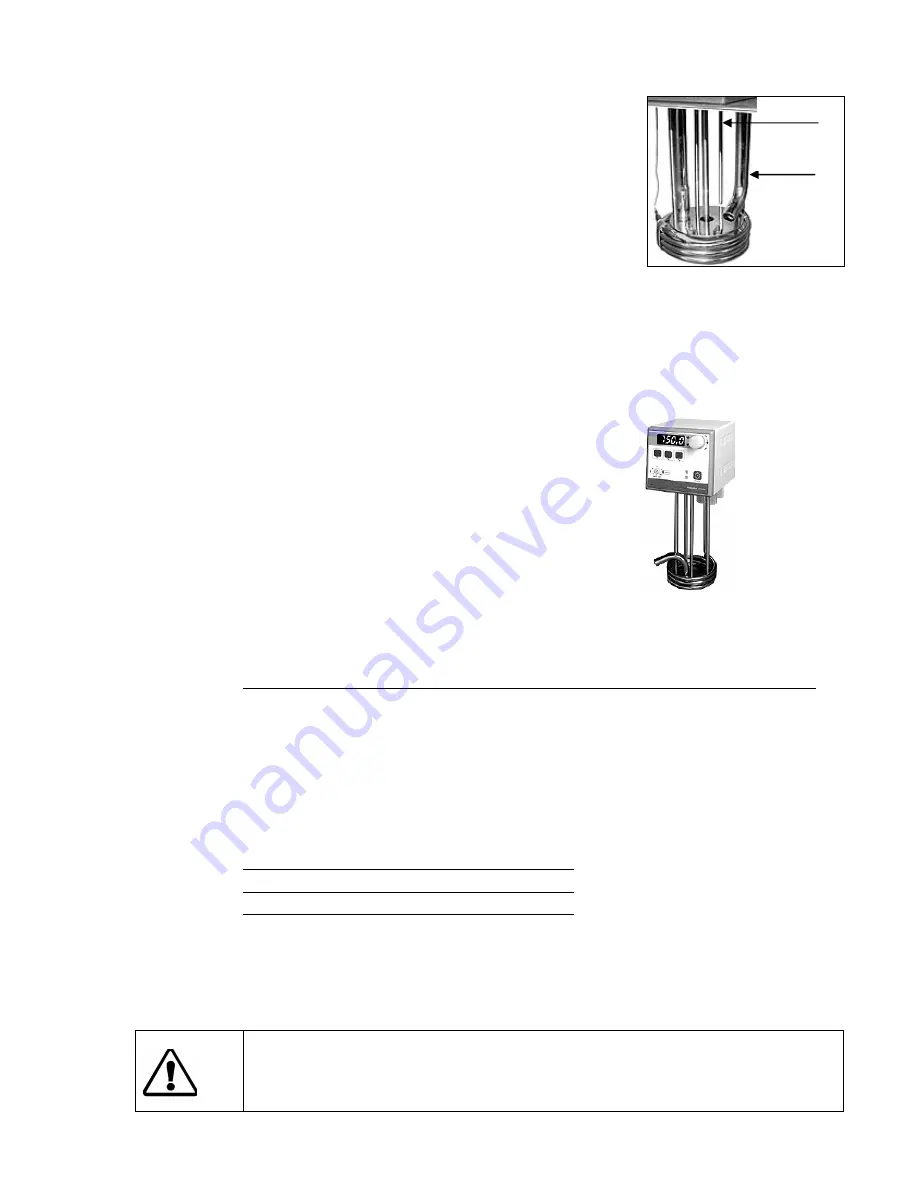

The maximum fill level for the Circulating bath is one inch

(25mm) below the top of the reservoir. A liquid level that fully

covers the heater coil, pump, over-temperature sensor, and at

least one inch (25mm) of the temperature sensor must be

maintained. For optimum cooling efficiency, the bath fluid level in

Refrigerating/Heating Circulators should be kept above the

cooling coils at all times.

Upon start-up, it may be necessary to add fluid to compensate

for the fluid required for external circulation. If the proper fluid

level is not maintained, the heater coil may become exposed and possibly damaged.

2.7

Reservoir Purge

When operating at low temperatures, atmospheric moisture tends to migrate into the reservoir and

condense. The 1/8 inch OD Reservoir Purge tube allows you to inject inert gas into the Circulating

bath to prevent the build-up of condensation.

Section 3- Immersion Circulator

3.1

Contents

— Immersion Circulator

— Operators Manual

— Warranty Card

— IEC Power Cord

3.2

General Description

Immersion Circulators with Standard Controller are designed for use in user-supplied reservoirs.

These units can be used with many sizes and shapes of reservoirs, making them extremely versatile

and useful for a wide variety of applications.

Model Type

Temperature

Range

Reservoir

Capacity

Amps @

120V, 60Hz

Amps @

240V, 50Hz

Heat Only

Immersion Circulator

5°C to 150°C*

N/A

11A

7.5A

3.3

Circulator Pump

The HIGH or LOW speed selection switch on the rear panel of the Controller is used to select pump

speed. LOW is adequate for most applications and provides quieter pumping. HIGH is

recommended where temperature varies frequently and there is a need for fast recovery or when

pumping to multiple external units.

Speed

Maximum Pump Outlet Ratings

Selection

Line Frequency = 50/60Hz

HIGH

15 LPM / 2.6 PSI

LOW

9 LPM / 1.5 PSI

The data in the table above are based on the following criteria:

1. Maximum pump outlet flow rate is measured in liters per minute (LPM) with no restriction on the pump outlet.

2. Maximum pump outlet pressure is measured in pounds per square inch (PSI) at no flow.

3. Water was used as the circulation fluid. Water has a viscosity of one centistoke. High viscosity or low-density

fluids will change these figures.

Warning

: These units are equipped with over-temperature protection (Safety Set). A low-liquid

level or failure to set the Safety Set and properly immerse the heater may result in heater

burnout and triac failure. While operating, do not allow the heater to contact any potentially

flammable materials, such as plastic racks or sides of plastic tanks, as a fire hazard may result.

Minimum

fill level

Temperature

Sensor