Ha Storing of Panels

Handling

•

When a

3

CeramicSteel panels are shipped, they

are protected by craft paper or a self-adhesive

transparent polyethylene film. Keep panels in the

original package until installation.

•

Handle with care to prevent damage.

•

Never slide panels off the stack during handling.

Panels should always be lifted and moved in a

vertical position.

•

Never place an a

3

panel in a vertical position on

the floor. This is to prevent damage to the edges.

•

Prevent dirt from settling on and between panels

to avoid surface damage, scratches or defects.

•

Follow all safety instructions regarding personal

protection when processing the panels.

•

Protect panel surface against sawdust and

sparks (metal particles).

•

a

3

CeramicSteel will chip when cut or drilled with

power tools. Hand-cutting can cause chipping

up to approx. 2 mm from the edge. When

chipping is in excess of 2 mm, please check the

state of cutting tools and check that the panel is

adequately supported and clamped to prevent it

from vibrating.

•

All cut or drilled sections should be protected

against humidity with PVC tape and/or by

covering/sealing profiles or sealing washers.

•

For detailed processing instructions, please refer

to the a

3

processing instructions.

Storing

• Keep panels dry and free of debris.

• Store panels inside temps 50-90 °F (10-32 °C).

• Any panels stored outside should be protected

from inclement weather conditions.

• Place panels on hard, flat surfaces that are not

subject to standing water.

• a

3

CeramicSteel panels should be stacked no

more than three high.

• Panels should never be stored vertically or in

such a way that the corners are vulnerable to

damage.

If you have a problem, question, or a request, call

your local fabricator, your regional sales manager

or PolyVision Customer Service. PolyVision’s global

customer service team can be contacted on

polyvision.com.

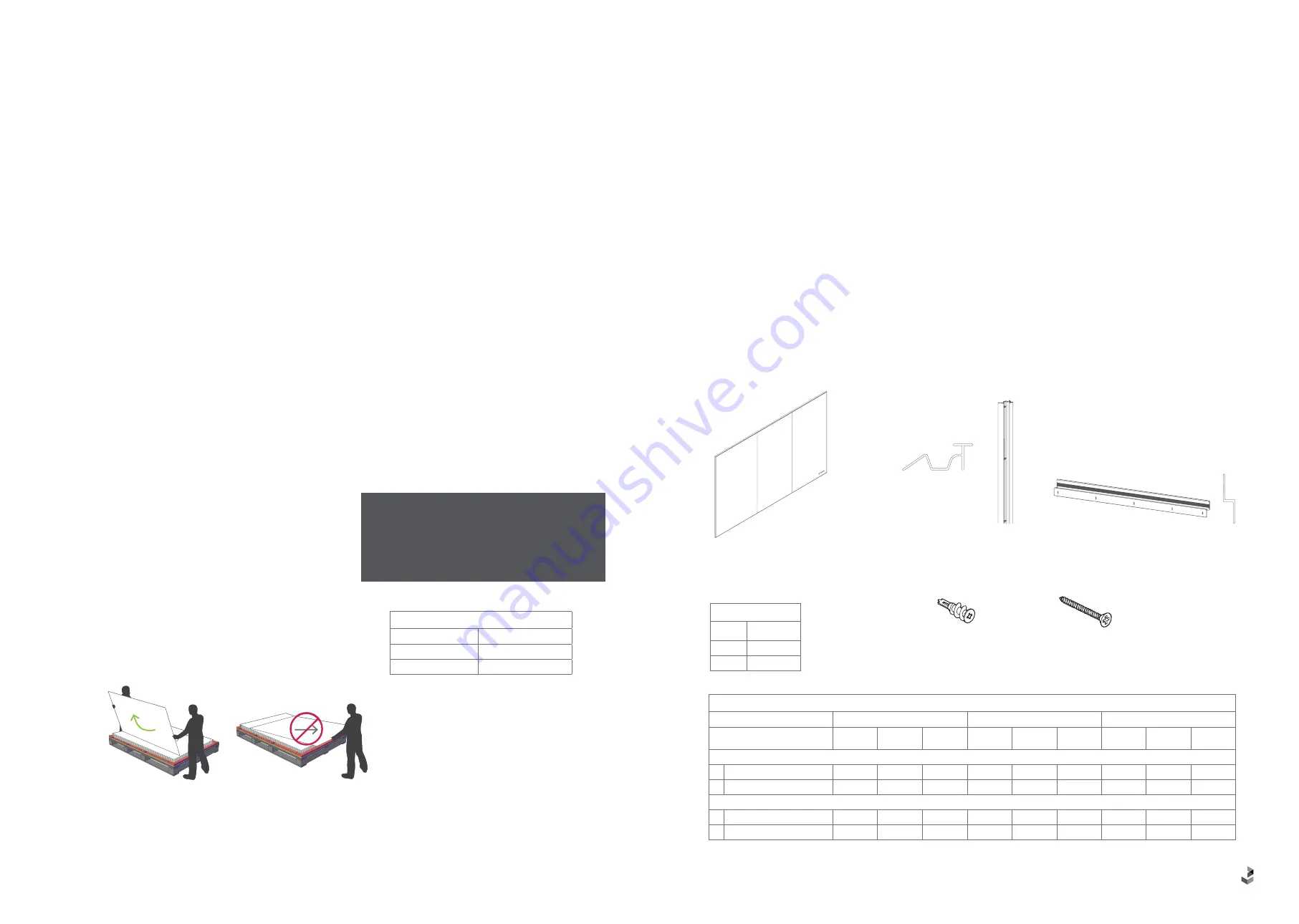

Table 1 Horizontal Installation

Product

Weight (kg/lb)/panel

Frameless Flow 1830

28 kg / 61.73 lb

Frameless Flow 2420

37 kg / 81.57 lb

•

Drill

•

#2 Bit

•

Glass suction cup lifters (2)

•

Pliers

•

Pencil

•

Level or laser

•

2 or 3-step ladder

• Tape measure

Required Mat Equipment

Required Equipment

Materials Provided

NOTE: Items are not drawn to scale. Quantity of wall anchors and screws will vary per product

due to the various widths. Board size determines the quantity of anchors and screws.*

Horizontal wall brackets

Vertical wall brackets

Horizontal oriented panels

or vertical oriented panels

Anchors

Screws

Table 2

Product

Panel A (right)

Panel B (intermediate)

Panel C (left)

# Vertical

Brackets

# Horizontal

Brackets

# Screws/

Anchors

# Vertical

Brackets

# Horizontal

Brackets

# Screws/

Anchors

# Vertical

Brackets

# Horizontal

Brackets

# Screws/

Anchors

Vertical Frameless Flow

Frameless Flow 1830

1

2

17

1

2

17

0

2

10

Frameless Flow 2420

1

3

24

1

3

24

0

3

15

Horizontal Frameless Flow

Frameless Flow 1830

1

2

15

1

2

15

0

2

10

Frameless Flow 2420

1

2

25

1

2

25

0

2

20

Frameless Flow Panels

Panel A

Right

Panel B

Intermediate

Panel C

Left

Doc # 143200 | Rev A | Page 5 of 38

Doc # 143200 | Rev A | Page 4 of 38