Automatic boiler for wood pellets

Instructions for installation and operation

4 STRUCTURAL DESCRIPTION OF PRODUCTS

The structure adheres to the Czech standard

Č

SN – EN 303.5 / 2000

-

i.e. boilers for central heating - part 5 (boilers for central heating with automatic fuel feed of rated

heat output up to 300 kW).

MAIN parts of the boiler are:

4.1 Boiler body

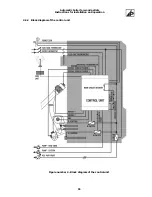

4.2 Control unit of the boiler

4.3 Burner furnace including the feeder 2 with independent drive

4.4 Ceramic parts

4.5 Feeder 1 with independent drive (from fuel bin)

4.6 Jacketing of the boiler including heat insulation

Other delivery:

4.7 Standard accessories

4.8 Optional accessories

4.9 Fuel bin

-

4.1 BOILER BODY

-

is made of top-quality steel metal sheets and pipes for boiler in form of a weldment. Its shape is

adapted in such a way so that combustion products are cooled down efficiently at individual levels of

power output, which is, moreover, assisted by a newly developed system of turbulator of combustion

products. The exchanger is shaped in such a way so that the exhaust pipes of combustion products can

be cleaned individually and efficiently.

The boiler body is fitted with the following:

-

1 piece of door which makes it possible to ignite the fuel, to control burning in course of

operation, to install a ceramic catalyst and ceramic extension grate before the operation is started

and to remove the ash pan when the ash is being cleaned.

-

exhaust

∅

130 – 150 - 160 mm

-

output of heating water G 1½´´ (inside thread)

-

input of return water G 1½´´ (inside thread)

-

rear flanged orifice in order to install the burner system

-

removable ash pan in the ash room

-

an outlet of ½´´ in order to install an inlet (outlet) valve

-

extension piece with inside thread M48 x 2 mm in order to make it possible to install an electrical

heating unit

-

turbulators (event. with system of semiautomatic cleaning of the heat exchanger)

-

lid of the boiler body

7

Summary of Contents for KP 10

Page 1: ......