User manual

PONSEL

Référence : NOTICE_ACTEON_2050_v001

V : 002

40/67

9 CONFIGURING ACTEON 2050

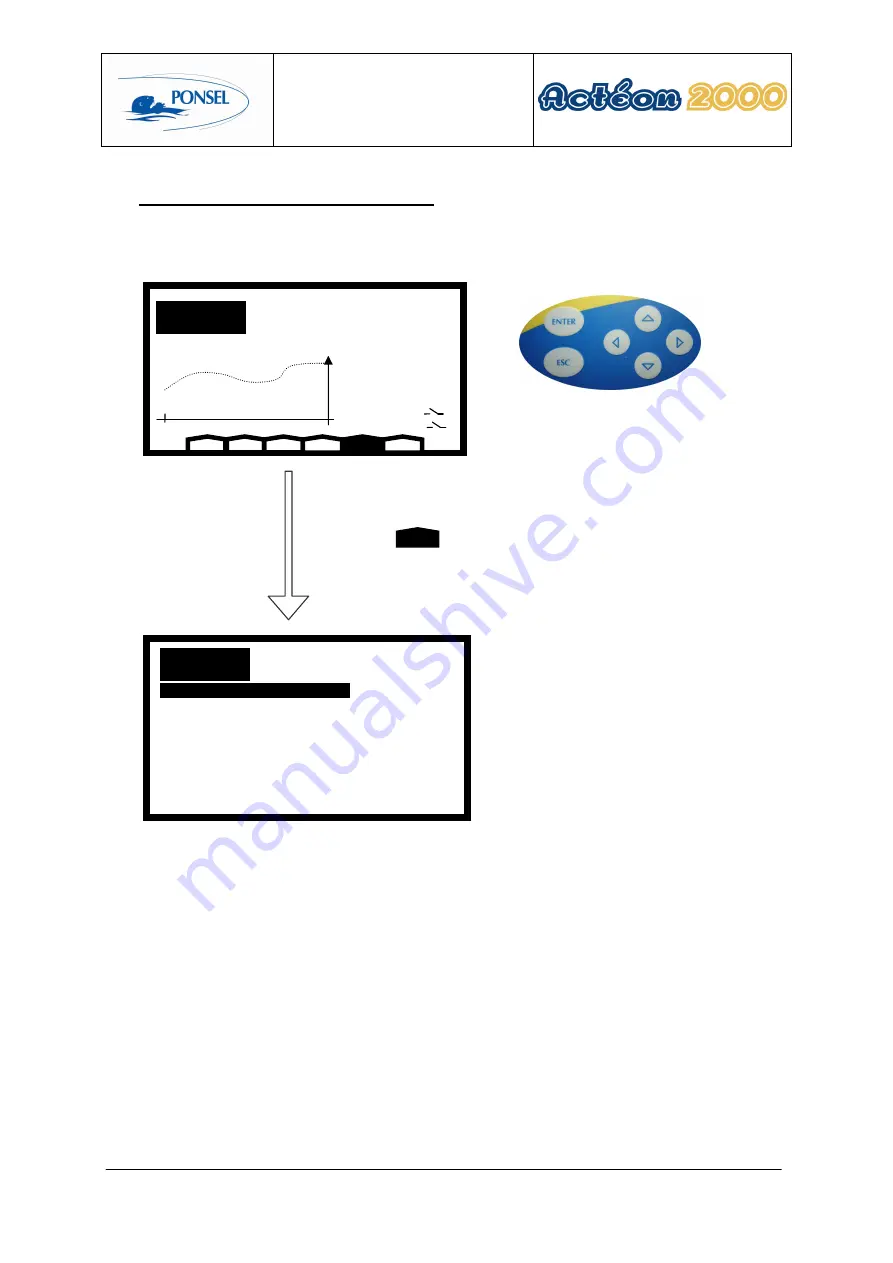

Select the configuration menu in the measurement window:

INFO

CONF

HIST CAL

LOG

MEAS

Use the

a

nd

keys to

navigate the ACTEON menu.

CONFIG

WHAT DO YOU WANT TO DO?

Averaging sensor response

Sludge slope coefficient reminder

Sensor offset adjustment

Graphic screen

4-20mA outputs adjustment

Relay adjustment

Measure units

Language

Factory default value reminder

ESC: Escape menu

Select the menu and press ENTER.

CONF

20.30

°C

-24 hrs

2.91

MEASURE

g/l

Mode1 R1

R2

ACTEON 2050-20 Turbidimeter

g/l

1

3