SAFETY INSTRUCTIONS

1. Always wear

eye protection

when operating the tool.

2. To avoid injury

do not point the tool at anyone.

3.

Do not exceed recommended maximum air pressure

(100 psi max.).

4.

Disconnect the tool from the air supply

when not in use for an extended period of time

or before proceeding with any maintenance procedures. Take care to control air hoses when dis-

connecting to prevent whipping.

5.

Do not attempt to operate the tool with the Nose Housing removed.

This exposes potential

pinch points and could result in injury.

6.

Do not tamper with the Clamp Screws or Fill Screw.

Loosened screws may result in

malfunction or injury due to air or hydraulic pressure.

7.

Do not operate the tool without either the deflector (PRT Option) or the collector (MCS

Option) installed on the tool.

Spent rivet mandrels may be forcefully ejected.

8.

Always clear the tool of spent rivet mandrels

before setting a new fastener. Failure to do so may

result in tool jams or forceful ejection of spent mandrels.

9.

Use caution when holding the tool at an angle

since compressed air is released through

the Intensifier Chamber and may be directed toward the operator. Do not direct exhaust towards

anyone.

10. Inspect the tool at regular intervals for damage and proper function.

Replace damaged parts

immediately. Do not connect a damaged tool to an air supply.

11.

Use only genuine Pop

®

brand replacement parts.

EMHART TEKNOLOGIES

• 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 •

www.emhart.com

Page 3

DESCRIPTION AND MODEL IDENTIFICATION

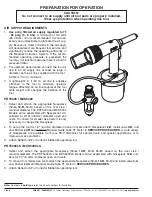

The 5400 Series tools are lightweight air-hydraulic Rivet Tools capable of setting all commercial blind

rivets up to and including 1/4" (6.4mm) diameter in all materials. Four models are available.

PRT5400

Standard model without mandrel collector.

MCS5400

Standard model with automatic vacuum mandrel collector attached.

PRT5400LS

Long stroke version without mandrel collector.

MCS5400LS

Long stroke version with automatic vacuum mandrel collector attached.

To determine model check length and height specifications or shipping carton label. Models PRT5400 and

MCS5400 are shipped set up for 3/16" (4.8 mm) and smaller diameter rivets. A simple front end parts change

is required to for setting larger diameter rivets. Refer to Service Procedures, Section 1 of this manual for more

information. All the necessary parts are included in the carton. Models PRT5400LS and MCS5400LS are

shipped set up for 1/4" (6.4 mm) diameter rivets. Parts to convert for smaller rivets are included in the carton.