EN

2.2.5

Electric lifting/pulling winch

(PCT1800 only)

The winch must be plugged into a

grounded plug. The use of an

extension cord can cause a loss of

power at full capacity. As listed on

the product label (figure 1), make

sure the voltage and current

type

are

respected.

Units

115V-60hz

require 20 amps while the units

220V-50hz require 10 amps.

2.2.6

Working cycle

The PCT1800 AC Electric Portable Capstan Pulling/Lifting Winch

TM

is

designed for intermittent use.

The engine

manufacturer

recommends an engine duty cycle of 25%. So, to get a maximum

lifetime out of the engine, it should only be used for fifteen (15)

minutes period every hour. This data varies depending on the loads

pulled or lifted. Light loads can be lifted or pulled continuously without

affecting the life of the engine. Continuous pulls are however less

damageable for the motor than frequents stop and go.

2.2.7

Capstan drum.

Your Portable Capstan Pulling/Lifting Winch

TM

is equipped with the

following capstan drum:

●

PCH1000•: Drum 57 mm (2-1/4") diameter.

●

PCH2000•: Drum 108 mm (4-1/4") diameter.

Only drum you can use with PCH2000 winch

●

PCT1800•: Drum 85 mm (3-3/8") diameter.

NOTE :

The maximum pulling force and the rated lifting capacity differ

according to the size of the drum used. Refer to section 5.5 Technical

Data to know the capacity with each drum. The PCH2000 can only

be used with the 108 mm (4-1/2") drum.

3.

Winch operation.

MOST

WINCHING

SITUATIONS

PRESENT

POTENTIAL

DANGERS

!

3.1

Rope type.

USE ONLY

LOW STRETCH 12 OR 13 MM (1/2'') DIAMETER

PORTABLE WINCH CO. DOUBLE BRAIDED POLYESTER ROPE

WITH A MINIMAL BREAKING POINT OF 3150 KG (6945 LB) WITH THIS WINCH. PLEASE

CONTACT US FOR OTHER ROPE TYPE'S SUITABILITY.

DO NOT USE 3-STRAND POLYPROPYLENE YELLOW ROPE!

●

POLYPROPYLENE AND POLYETHYLENE ROPES ARE DANGEROUS FOR

WINCHING BECAUSE OF THEIR GREAT ELASTICITY AND LOW MELT POINT.

●

MAKE SURE THE ROPE IS NOT DAMAGED AND THAT IT OFFERS AN ADEQUATE

RESISTANCE TO PULL THE LOAD.

STRETCH = DANGER!

●

A STRETCHED ROPE CAN RECOIL AND CAUSE SERIOUS BURNS AS THE ROPE

LEAVES YOUR HAND.

●

ALL ROPES STRETCH: A LONGER ONE MORE THAN A SHORTER ONE. THE MORE

YOU PULL, THE MORE IT STRETCHES.

●

A STRETCHED ROPE CAN ALSO MOVE THE LOAD IN AN UNPREDICTABLE OR

DANGEROUS WAY.

●

A STRETCHED ROPE CAN RECOIL AND BRING YOUR HAND TOWARDS THE

WINCH CAUSING SEVERE INJURIES. NEVER WRAP THE ROPE AROUND YOUR

HAND.

ALWAYS WEAR GLOVES.

3.1.1 Rope usage

Use rope properly; do not abuse or shock load it. Observe

recommended usage factors for bending and work loads. Keep

ropes clean and eliminate abrasion whenever possible.

1)

Working loads are the loads that a rope is subjected to in

everyday activity. For lifting purposes we recommend a

minimum safety factor of 7 (app. 15% of the rope minimum break

strength) when the rope has a spliced termination. If the rope is

knotted with a bowline, we recommend a safety factor of 10.

2)

Any sharp bend in a rope under load decreases rope strength

substantially and may cause permanent damage and failure.

Sheave diameters should be 8 times the rope diameter.

3)

Knots are known to reduce rope strength but they are a

convenient way to accomplish rope attachment. The strength

loss is a result of the sharp bends that occur in the knots. If you

must use a knot, use the bowline or double bowline described in

section 3.1.3.

4)

Keep rope clean and as dry as possible. Grit and dirt will work its

way inside the rope and degrade it rapidly. You can wash it in

the washing machine and hang to dry.

5)

Store the rope in a rope bag or in a pail. Coiling the rope will

induce twists and knots.

6)

Shock loads are a sudden change in tension from a relaxed

state or low load to one of high load. Any sudden load that

exceeds the work load by more than 10% is considered a shock

load. The further an object falls, the greater the impact. Synthetic

fibers have a memory and retain the effects of being overloaded

and can fail at a later time even though loaded within the work

load range.

3.1.2 Rope inspection and maintenance

VISUALLY INSPECT YOUR ROPE BEFORE EACH USAGE. IF IT

SHOWS ANY SIGN OF DETERIORATION (CUT STRANDS,

EXCESSIVE ABRASION), REPLACE IT.

IF YOUR ROPE IS DIRTY, WASH IT. DIRTY ROPES DETERIORATE

FASTER AND CAUSE PREMATURE WEAR OF THE PARTS IN

CONTACT WITH THE ROPE SUCH AS THE CAPSTAN DRUM AND ROPE GUIDE.

Any rope that has been used for any period will show normal wear

and tear. Some characteristics of a used rope will not reduce

strength while others will. Below are the conditions that should be

inspected on a regular basis.

Double braid ropes consist of a cover or jacket braided over a

separately braided core. The strength of the double braid rope is

shared between the cover and the core. Damage to the cover also

usually affects the core and ultimately the strength of the rope.

Rope inspection is done by running both hands over the entire length

of the rope while turning it in order to see all around. It is a visual as

well as a touch feeling process.

TWIST :

Every time you set the rope over the capstan drum you are twisting

the rope. Depending on the length of the rope, and what percentage

of the rope you use, you will sooner or later have a twisted rope with

reduced capacity because the strands are not loaded evenly. You

can un-twist the rope by spinning the rope to a free end. It is a good

practice to reverse the rope - use both ends. In addition to help with

the twist problem, the rope will also wear more evenly.

GREY COLOR :

This comes from aluminium residues

from the friction on the capstan drum.

Your hands will get dirty but this does

not damage the rope.

4

Summary of Contents for PCH1000

Page 14: ...14 DE Annex PCH1000 ...

Page 15: ...15 DE Annex PCH2000 ...

Page 16: ...16 DE Annex PCT1800 50Hz P PCT1800 60Hz P ...

Page 17: ...17 DE Annex Diagramm PCT1800 50Hz P PCT1800 60Hz P ...

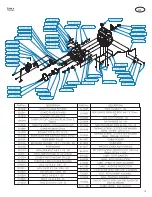

Page 34: ...14 EN Annex PCH1000 ...

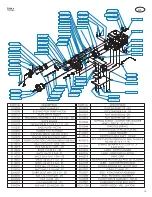

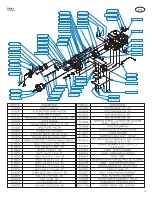

Page 35: ...15 EN Annex PCH2000 ...

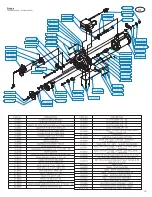

Page 36: ...16 EN Annex PCT1800 50Hz P PCT1800 60Hz P ...

Page 37: ...17 EN Annex diagram PCT1800 50Hz P PCT1800 60Hz P ...

Page 54: ...14 FR Annexe PCH1000 ...

Page 55: ...15 FR Annexe PCH2000 ...

Page 56: ...16 FR Annexe PCT1800 50Hz P PCT1800 60Hz P ...

Page 57: ...17 FR Annexe diagramme PCT1800 50Hz P PCT1800 60Hz P ...