8

AUTOMATISMO

Condensador

8μF

1

2

3

2

COM 1

COM 2

COM

Fio

Terra

Fase 2

Fase 1

Abre

Fecha

Motor

Alimentação 1

Alimentação 2

• Check all operator controls such as the floor plate,

the limit switches, the motor and the rack.

MAINTENANCE

These maintenance measures must be carried out within 6 months to maintain the correct operation of the

operator.

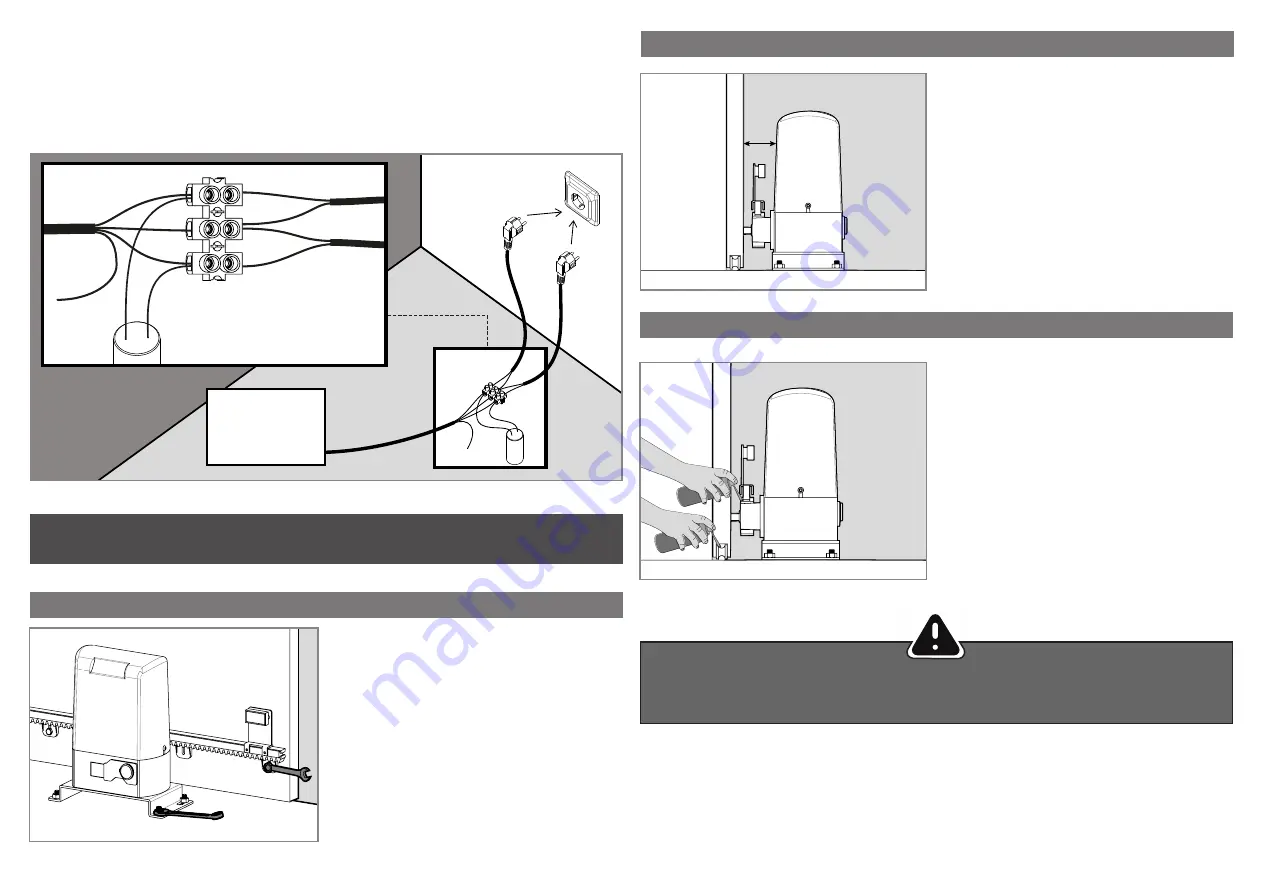

1 • Connect the power wires to the terminal, as shown.

2 • Connect the operator wires to the terminal, inserting a capacitor into the opening and closing wires.

3 • After these connections are completed, connect to a 230V outlet, depending on the motor/power unit being

tested.

LUBRIFICATING COMPONENTS

CHECK FRICTION BETWEEN RACK AND PINION

CHECK DISTANCES AND TIPS

63

• Make sure that the distance between rack and motor

remains unchanged and that it engages the teeth of the

motor pinion correctly (over time, some distortion may

occur).

• Lubricate all gate drive systems/shafts. Lightly lubri-

cate the pinion and the rack.

OPERATOR

Capacitor

8μF

1

2

3

2

COM 1

COM 2

COM

Ground

Wire

Phase 2

Phase 1

Abre

Fecha

Motor

Power Supply 2

Power Supply 1