15

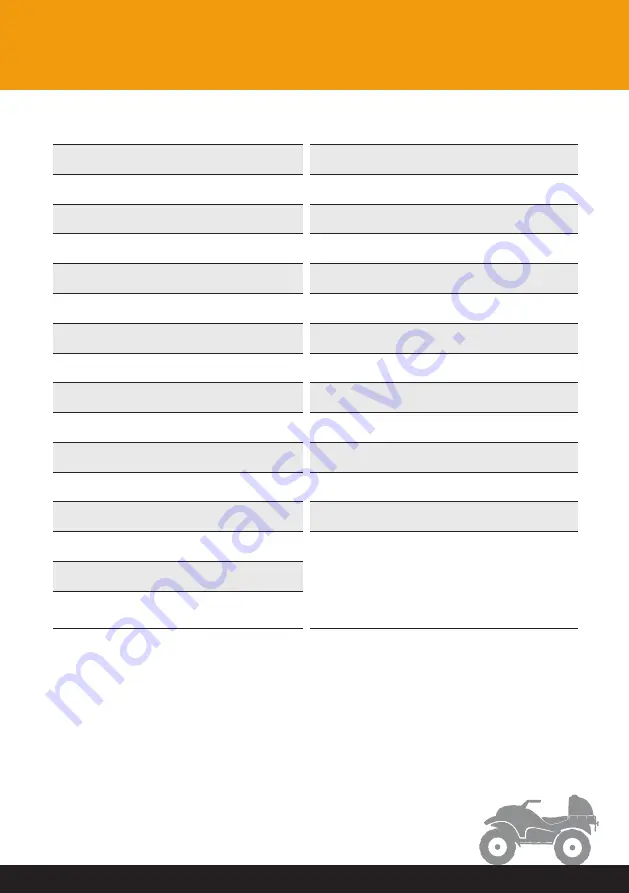

Parts List

No.

Part No. Description

No.

Part No. Description

1

088/007 Powerjet Spray Lance

13 088/042

3

/

4

” Ball Drain Valve

1

088/008 Economy Spray Lance

14 088/022

1

/

2

” Mini Ball Valve F/F

2

088/136 60L Sprayer Tank

15 088/023 Reducer

1

/

2

”m x

3

/

4

”m

2

088/137 90L Sprayer Tank

16 088/014 Suction Filter

(10mm)

3

088/003 3.8L/min Pump

16 088/011 Suction Filter

(13mm)

3

088/004 8.3L/min Pump

17 088/070 1m Spray Hose

(10mm)

3

088/005 15.0L/min Pump

17 088/097 1m Spray Hose

(13mm)

4

088/006 150mm Screw Lid

18 088/068

3

/

8

” Hose Clamp

5

088/045 Basket Filter

19 088/016

3

/

8

” Top Hat Grommet

(Suction)

6

088/017 2.4m 12v Electrical Leads

19 088/015

1

/

2

” Top Hat Grommet

(Suction)

7

088/019 Pressure Regulator

20 088/015

1

/

2

” Top Hat Grommet

(Return)

8

088/021 12mm Threaded Elbow

21 088/025 M5 x 25 Screws BZP

9

088/020 19mm Elbow x13mm HB

22 088/024 M5 Washer

10

088/068

3

/

8

” Hose Clamp

23 088/146

Hose Wrap Kit includes:

wrap brackets, fixings, bungee

loop and hose clip (must be

positioned where shown)

11 088/070A 6m Spray Hose

(10mm)

12

088/018 Gauge 0-100 Psi