10

CAUTION:

Ensure rear handle is locked into one of the three

locations before turning tool on to prevent loss of control, damage

to the machine, and bodily injury.

USING A DISC SANDER

1.

CAUTION:

Secure work to prevent it from moving during the sanding

operation. Friction between the sanding disc and work will try to spin work

away from sander and may cause bodily injury.

2.

CAUTION:

WEAR SAFETY GLASSES AND DUST MASK.

3.

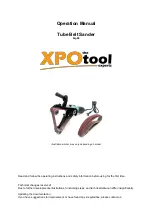

Hold sander firmly by the rear and auxiliary handles, making sure

sanding disc is clear of work and foreign objects. Start sander and lower so

that sanding disc is FLAT on work surface, Fig. 6.

4.

Move sander in long sweeping overlapping strokes as you go back and

forth. Do not move sander in a circular motion or stay in one spot too long as

this will produce swirls and an uneven finish. The weight of the sander

applies sufficient pressure for fast stock removal. Additional pressure will

only slow the sander down and decrease removal of stock.

5.

LIFT SANDER FROM WORK BEFORE TURNING OFF MOTOR.

6.

Always be sure motor has stopped before setting sander down.

SANDING TIPS

For rough sanding and quick stock removal, use a coarse grit sanding disc.

For a fine finish, use a medium grit disc, followed by a fine grit disc. Do not

go directly from a coarse grit to a fine grit, as it is difficult to remove marks

left by the coarse grit disc.

USING A DISC GRINDER

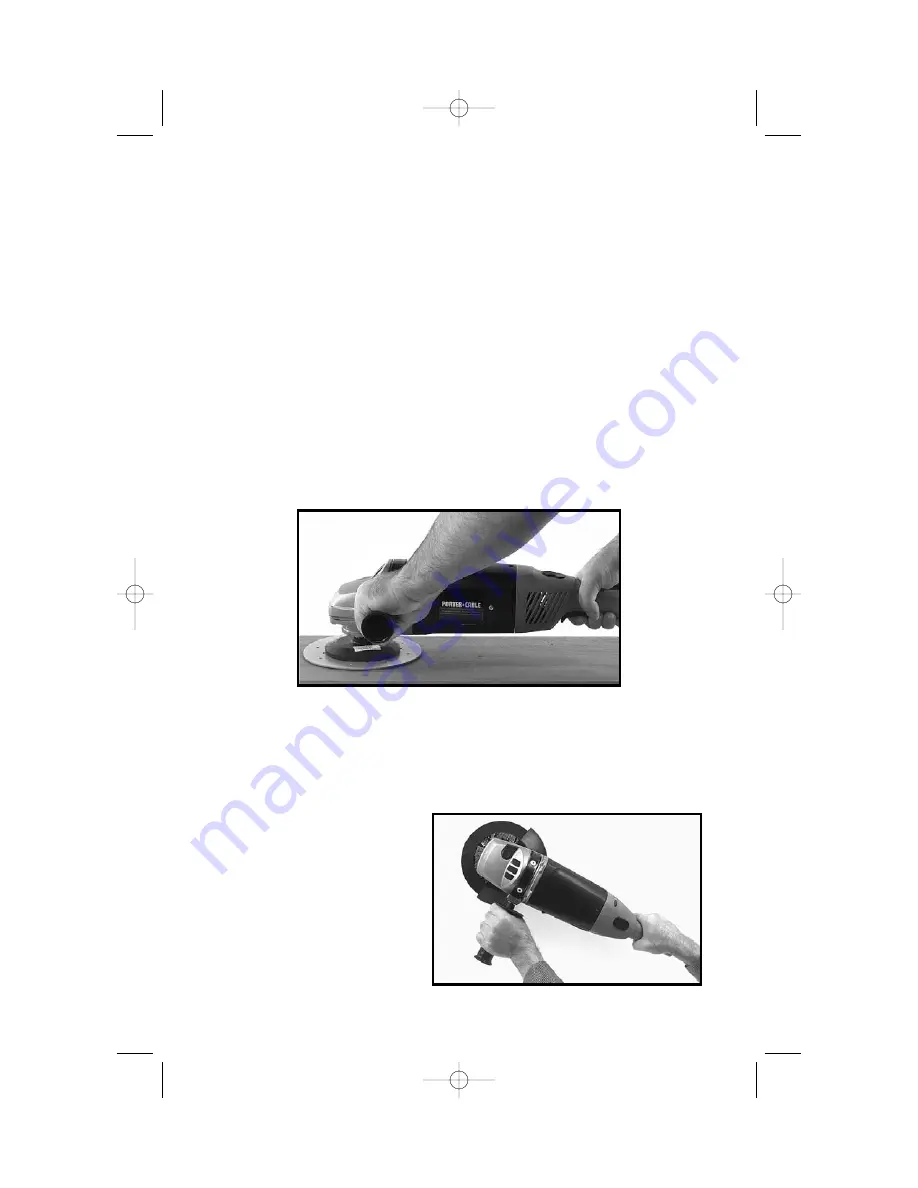

Be certain wheel guard and

auxiliary handle are installed.

Firmly grip the auxiliary handle

and motor housing as shown in

Fig. 7. Lift up rear of motor

housing so only the front

section of grinding wheel

contacts the work. Use light

pressure. Always lift the grinder

off work before starting or

stopping motor. The arrow on

Fig. 6

Fig. 7

283800 - 07-31-00.QXD 9/23/02 1:34 PM Page 10