• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA respiratory protection.

Before operating this tool, carefully read and understand all instructions in Important

Safety Instructions.

ASSEMBLY

Disconnect the tool from the air supply and remove fasteners from

magazine before making adjustments or personal injury may result.

TRIGGER

Keep fingers AWAY from trigger when not driving fasteners to avoid accidental

firing. Never carry tool with finger on trigger. In bump action mode (contact actuation mode)

tool will drive a fastener if contact trip is bumped while trigger is pulled.

In accordance with the ANSI Standard SNT-101-2002, the PORTER-CABLE nailers are

assembled with a sequential action trigger.

NOTE: However, a bump action trigger kit may be

purchased. For a replacement trigger or to order a bump action trigger contact your authorized

service center or call 1-888-848-5175.

to ReplAce seqUentiAl tRiggeR

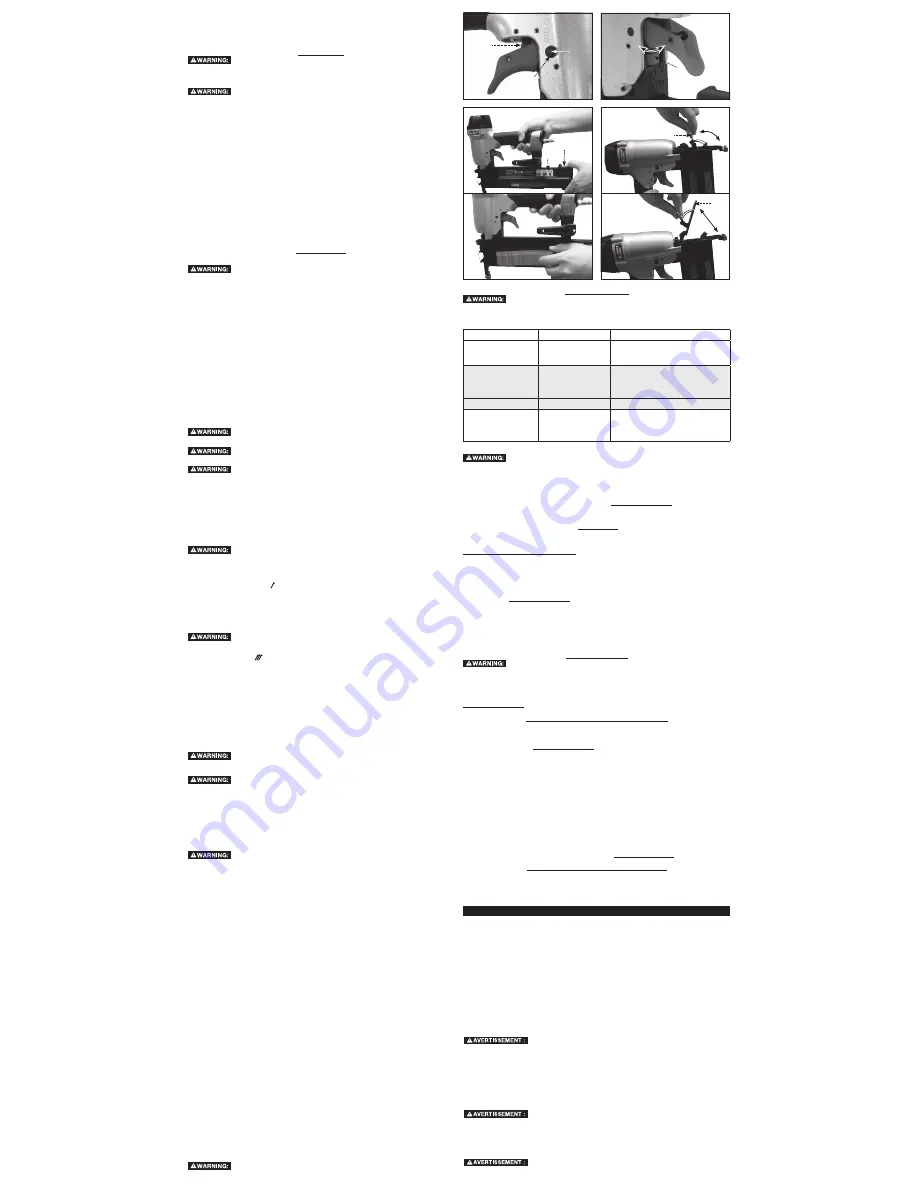

Trigger Removal (Fig. 2)

1. Disconnect the tool from the air supply.

2. Remove rubber grommet (N) from end of trigger pin (M).

3. Remove trigger pin.

4. Remove trigger assembly from trigger cavity under the handle of the tool housing.

Trigger Installation

1. Insert the trigger kit into trigger cavity.

2. Ensure that trigger spring (O) is placed around the trigger valve stem.

3. Align the holes of the trigger with the housing holes, then insert the trigger pin (M)

through the entire assembly.

4. Push the rubber grommet (N) onto the end of the trigger pin.

OpERATION

pREpARING THE TOOL

Read the section titled

Important Safety Instructions for Pneumatic Tools

at the beginning of this manual. Always wear proper eye [ANSI Z87.1 (CAN/CSA Z94.3)] and

hearing protection [ANSI S12.6 (S3.19)] when operating this tool. Keep the nailer pointed

away from yourself and others. For safe operation, complete the following procedures and

checks before each use of the nailer.

NOTE: These nailers are designed to be used without oil.

1. Before you use the nailer, be sure that the compressor tanks have been properly

drained.

2. Wear proper eye, hearing and respiratory protection.

3. Lock the magazine release in the back position and remove all fasteners from the

magazine.

4. Check for smooth and proper operation of contact trip and pusher assemblies. Do not

use tool if either assembly is not functioning properly. NEVER use a tool that has the

contact trip restrained in the up position.

5. Check air supply. Ensure that air pressure does not exceed recommended operating

limits; 70 to 120 psi, (4.9 to 8.3 bar, 5 to 8.5 kg/cm

2

).

6. Connect air hose.

7. Check for audible leaks around valves and gaskets. Never use a tool that leaks or has

damaged parts.

LOADING THE TOOL (Fig. 3)

Keep the tool pointed away from yourself and others. Serious personal injury

may result.

Never load fasteners with the contact trip or trigger activated. Personal injury

may result.

Always disconnect the tool from the air supply before making any

adjustments or attemping any repairs to the tool.

1. Read all

safety Warnings before using tool.

2. Connect the tool to air supply.

3. Push magazine release (F) and pull magazine (E) back.

4. Insert fasteners into the side of the magazine. Be sure the fasteners ride on their tips

in the nail channel.

5. Push magazine closed until it locks in place.

ACTUATING TOOL

To reduce the risk of injury,

AlWAYs wear proper eye [ANSI Z87.1 (CAN/

CSA Z94.3)] and hearing protection [ANSI S12.6 (S3.19)] when operating this tool.

The tool can be actuated using one of two modes: single sequential action trigger mode and

bump action trigger mode.

Sequential action trigger -

Red trigger (Fig. 1)

The sequential action triger’s intended use is for intermittent fastening where very careful and

accurate placement is desired.

To operate the nailer in sequential action mode:

1. Depress the contact trip firmly against the work surface.

2. Pull the trigger.

A fastener will be driven each time the trigger is pulled as long as the contact

trip remains depressed which could result in accidental driving.

Bump action trigger -

Black trigger (Fig. 1)

The bump action trigger’s intended use is for rapid fastening on flat, stationary surfaces.

Using the bump action trigger, two methods are available:

place actuation and bump

actuation.

To operate the tool using the pLACE ACTUATION method:

1. Pull the contact trip against the work surface.

2. Pull the trigger.

To operate the tool using the BUMp ACTUATION method:

1. Pull the trigger.

2. Push the contact trip against the work surface. As long as the trigger is pulled, the tool

will drive a fastener every time the contact trip is depressed. This allows the user to

drive multiple fasteners in sequence.

Do not keep trigger pulled when tool is not in use.

ADJUSTING DEpTH (Fig. 4)

To reduce risk of serious injury from accidental actuation when attempt-

ing to adjust depth, AlWAYs:

• Disconnect the tool from the air supply.

• Avoid contact with trigger during adjustments.

The depth that the fastener is driven can be adjusted using the depth adjustment next to the

trigger of the tool.

1. To drive the fastener shallower, rotate the depth setting wheel (K) to the right.

2. To drive a fastener deeper, rotate the depth setting wheel (K) to the left.

CLEARING A JAMMED NAIL (Fig. 5)

Disconnect the tool from the air supply and remove fasteners from

magazine before making adjustments or personal injury may result.

If a nail becomes jammed in the nosepiece, keep the tool pointed away from you and follow

these instructions to clear:

1. Disconnect the tool from the air supply.

2. Release magazine release (F) from behind nails.

3. Push down jam clearing latch (A) then pull up to open front door (P).

4. Remove bent nail, using pliers if necessary.

5. If driver blade is in the down position, insert screwdriver or other rod into nosepiece

and push driver blade back in position.

6. Remove rod and close front door.

7. Lift latch to secure door to nosepiece.

8. Reinsert nails into magazine (see

Loading the Tool).

9. Release magazine release (F).

10. Reattach air supply.

NOTE: Should nails continue to jam frequently in nosepiece, have tool serviced by an

authorized PORTER-CABLE service center.

colD WeAtheR opeRAtion

When operating tools at temperatures below freezing:

1. Make sure compressor tanks have been properly drained prior to use.

2. Keep tool as warm as possible prior to use.

3. Make certain all fasteners have been removed from magazine.

4. Lower air pressure to 80 psi or less.

5. Reconnect air and and load nails into magazine.

6. Actuate the tool 5 or 6 times into scrap lumber to lubricate o-rings.

7. Turn pressure up to operating level (not to exceed 120 psi) and use tool as normal.

8. Always drain the compressor tanks at least once a daily.

hot WeAtheR opeRAtion

Tool should operate normally. However, keep tool out of direct sunlight as excessive heat can

deteriorate bumpers, o-rings and other rubber parts resulting in increased maintenance.

BELT HOOK (Fig. 1)

The PORTER-CABLE nailers include an integrated belt hook (I) and can be hooked to either side

of the tool to accommodate left or right handed users.

If the hook is not desired at all, it can be removed from the tool.

To remove belt hook:

1. Disconnect the tool from the air supply.

2. Lift the lever and slowly move the belt hook to the direction of the trigger.

Never use belt hook with bump action trigger installed on tool.

MAINTENANCE

Disconnect the tool from the air supply and remove fasteners from maga-

zine before making adjustments or personal injury may result.

DAILY MAINTENANCE CHART

ACTION

WhY

hoW

Drain compressor

tanks and hoses daily.

Prevents accumulation

of moisture in

compressor and nailer.

Open petcocks or other drain valves on

compressor tanks. Allow any

accumulated water to drain from hoses.

Clean magazine,

magazine release and

contact trip mechanism.

Permits smooth

operation of magazine,

reduces wear and

prevents jams.

Blow clean with compressor air. The

use of oils, lubricants periodically

or solvents is not recommended

as they tend to attract debris.

ACTION

WhY

hoW

Before each use, check

to insure all screws,

nuts and fasteners are

tight and undamaged.

Prevents jams, leaks

and premature

failure of tool parts.

Tighten loose screws or other

fasteners using the appropriate

hex wrench or screwdriver.

CLEANING

Never use solvents or other harsh chemicals for cleaning the non-metallic

parts of the tool. These chemicals may weaken the materials used in these parts. Use a

cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid.

REpAIRS

For assistance with your tool, visit our website at www.portercable.com for a list of service

centers, or call the PORTER-CABLE Customer Care Center at 1-888-848-5175 (U.S. & Canada

Only).

SERvICE

REpLACEMENT pARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at

http://servicenet.deltaportercable.com/. You can also order parts from your nearest PORTER-

CABLE Factory Service Center or PORTER-CABLE Authorized Warranty Service Center. Or,

you can call our Customer Care Center at 1-888-848-5175 (U.S. & Canada Only).

SERvICE AND REpAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information

about PORTER-CABLE, its factory service centers or authorized warranty service centers, visit

our website at www.portercable.com or call our Customer Care Center at 1-888-848-5175

(U.S. & Canada Only). All repairs made by our service centers are fully guaranteed against

defective material and workmanship. We cannot guarantee repairs made or attempted by

others.

You can also write to us for information at PORTER-CABLE, 4825 Highway 45 North, Jackson,

Tennessee 38305 - Attention: Product Service. Be sure to include all of the information shown

on the nameplate of your tool (model number, type, serial number, etc.).

ACCESSORIES

Since accessories other than those offered by Porter-Cable have not been

tested with this product, use of such accessories could be hazardous. For safest operation,

only Porter-Cable recommended accessories should be used with this product.

A complete line of accessories is available from your PORTER-CABLE Factory Service

Center or a PORTER-CABLE Authorized Warranty Service Center. Please visit our Web Site

www.portercable.com for a catalog or for the name of your nearest supplier.

thRee YeAR liMiteD WARRAntY

PORTER-CABLE will repair, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase. This warranty does not cover part

failure due to normal wear or tool abuse. For further detail of warranty coverage and warranty

repair information, visit www.portercable.com or call 1-888-848-5175 (U.S. & Canada Only).

This warranty does not apply to accessories or damage caused where repairs have been

made or attempted by others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, PORTER-CABLE tools are covered by our:

1 YEAR FREE SERvICE: PORTER-CABLE will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with the

performance of your PORTER-CABLE Power Tool, Laser, or Nailer for any reason, you

can return it within 90 days from the date of purchase with a receipt for a full refund – no

questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained in the

packaging, call the local company or see website for warranty information.

To register your tool for warranty service visit our website at www.portercable.com.

WARning lABel ReplAceMent

If your warning labels (Fig. 6) become illegible or are missing, call 1-888-848-5175 (U.S. &

Canada Only). for a free replacement.

Fig. 2

M

N

Fig. 4

K

O

Fig. 3

Fig. 5

F

F

E

A

p

E

Détente à Action séqUentielle

• lorsqu’on utilise la détente par action séquentielle, ne pas actionner l’outil à

moins qu’il ne soit fermement appuyé contre la pièce.

• RéglAge De lA pRofonDeUR : pour réduire les risques de blessures graves lors

de l’actionnement intempestif de l’outil lorsqu’on tente de régler la profondeur,

TOUJOURS :

• débrancher la source d’alimentation en air;

• éviter tout contact avec la détente lors des réglages.

• ne pas enfoncer des clous à l’aveuglette dans les murs, les planchers et autres

zones de travail. Des attaches enfoncées dans des fils électriques sous tension, de la

plomberie ou d’autres types d’obstacles peuvent entraîner des blessures. (fig. U)

• Rester vigilant, faire attention au travail en cours et faire preuve de jugement dans

l’utilisation de tout outil électrique. Ne pas utiliser d’outil en cas de fatigue ou sous

l’emprise de drogues, d’alcool ou de médicaments. Un simple moment d’inattention en

utilisant un outil électrique peut entraîner des blessures corporelles graves.

L'utilisation de ce produit peut vous exposer à des substances

chimiques reconnues par l'état de Californie pouvant causer le cancer et des malformations

congénitales ou autres dommages reproducteurs.

éviter d'inhaler les vapeurs et la

poussière et se laver les mains après l'utilisation.

• éviter le contact prolongé avec les poussières produites par les activités de

ponçage, sciage, meulage, perçage et autres activités de construction. Porter des

vêtements de protection et laver les parties du corps exposées avec une solution d’eau

et de savon. Le fait de laisser la poussière pénétrer dans la bouche et les yeux ou de la

laisser reposer sur la peau peut promouvoir l’absorption de produits chimiques nocifs.

l’utilisation de cet outil peut produire et/ou dégager des poussières

qui risqueraient de causer des problèmes respiratoires graves et permanents ou d’autres

problèmes médicaux. Toujours porter un appareil respiratoire approuvé par la NIOSH/OSHA

pour se protéger de la poussière. Diriger les particules loin du visage et du corps. Toujours

utiliser l’outil dans des endroits bien aérés et veiller à dépoussiérer correctement la zone de

travail. Utiliser un système de dépoussiérage lorsque c’est possible.

TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Les lunettes

ordinaires ne constituent PAS des lunettes de sécurité. Utiliser également un masque

français continué