Drain Valve:

The

drain valve is located

at the base of the air

tank and is used to

drain condensation at

the end of each use.

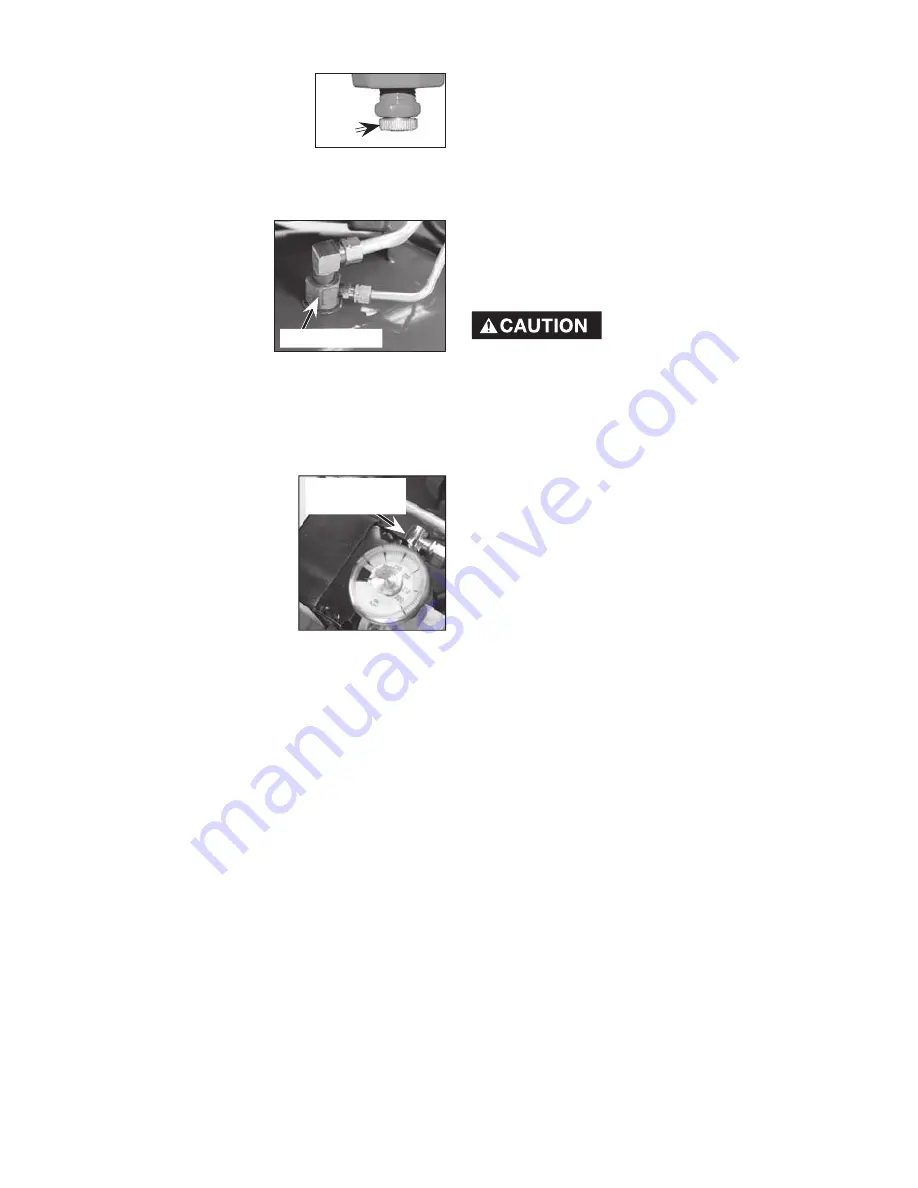

Check Valve:

When the air

compressor is

operating, the

check valve

is "open",

allowing

compressed

air to enter

the air tank.

When the

air compressor reaches "cut-out"

pressure, the check valve "closes",

allowing air pressure to remain inside

the air tank.

Pressure Release Valve:

The

pressure release

valve located on

the side of the

pressure switch,

is designed to

automatically

release

compressed

air from the

compressor head

and the outlet tube when the air

compressor reaches "cut-out" pressure

or is shut Off. The pressure release

valve allows the motor to restart freely.

When the motor stops running, air will

be heard escaping from this valve for a

few seconds. No air should be heard

leaking when the motor is running

or after the unit reaches "cut-out"

pressure.

Motor Overload Protector (not

shown):

The motor has an automatic

reset thermal overload protector. If

the motor overheats for any reason,

the overload protector will shut

Off the motor. The motor must

be allowed to cool down before

restarting. The compressor will

automatically restart after the motor

cools.

12 - ENG

A09770

Check Valve

Before First Start Up

Risk of Unsafe

Operation. Serious

damage may result if the following

break-in instructions are not

closely followed.

This procedure is required

before

the

air compressor is put into service and

when the check valve or a complete

compressor pump has been replaced.

1. Make sure the On/Auto/Off lever

is in the "Off" position.

2. Plug the power cord into the

correct branch circuit receptacle.

(Refer to Voltage and Circuit

Protection paragraph in the

Installation section of this

manual.)

3. Open the drain valve (counter-

clockwise) fully to permit air to

escape and prevent air pressure

build up in the air tank during the

break-in period.

4. Move the On/Auto/Off lever

to "On/Auto" position. The

compressor will start.

5. Run the compressor for 15

minutes. Make sure the drain

valve is open and there is

minimal air pressure build-up in

tank.

6. After 15 minutes, close the drain

valve by turning clockwise. The

air receiver will fill to "cut-out"

pressure and the motor will

stop.

The compressor is now ready for use.

Pressure

Release Valve

How to Use Your Unit

How to Stop:

1. Set the On/Auto/Off lever to

"Off".

Drain

Valve

Air Intake Filter (not shown):

This

filter is designed to clean air coming

into the pump. This filter must always

be clean and ventilation openings free

from obstructions. See "Maintenance".

Summary of Contents for CFFC350C

Page 21: ...21 ENG A09770 NOTES...