11

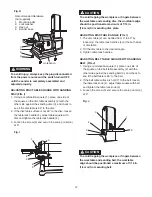

INSTALLING DUST EXHAUST AND DUST BAG

(FIG. E, F )

Sanding operations are inherently dusty. To help

minimize the amount of dust that escapes into the

surrounding air, this sander is equipped with a dust

exhaust and dust bag. It is strongly recommended

that users attach the dust exhaust and the dust bag

when using this belt / disc sander.

Use of a mask or

respirator is still recommended even when a dust-

collection system is in use.

1. Raise the belt bed (1) and secure in the vertical

position.

2. Loosen the inner hex screw (2) using the 5 mm hex

key, attach the dust exhaust (3) on the dust port (4)

of the sander, and tighten the inner hex screw (2).

Fig. E

3. Insert the opening of dust bag (5) through the bag

clamp (6), and release the clamp handle (7).

4. Attach the the opening of dust bag (5) to the dust

exhaust (3), slide the bag clamp (6) over the bag and

exhaust and lock the bag clamp (6) to secure the

dust bag (5).

Fig. F

NOTE:

Turn the clamp handle (7) clockwise a full turn or

two before locking to give a tight fit. Do not overtighten.

CAUTION

!

1

3

4

2

7

5

3

6

MITER GAUGE (FIG. G)

A miter gauge (1) is supplied with your sander and can

be used with both sanding tables. The miter gauge body

can be adjusted from 0° to 60° right or left for angle or

miter sanding.

1. Install the miter bar (2) into the table slot (3) as

shown.

2. Loosen lock knob (4) and then rotate miter gauge

body to the desired angle.

3. Tighten lock knob.

Fig. G

MOUNTING BELT / DISC SANDER TO WORKBENCH

(FIG. H)

If during operation there is any tendency for the

sander to tip over, slide or walk on the supporting

surface, it is recommended that you mount the

sander on a flat and level workbench or stand

to avoid any movement during operation. Four

mounting holes are located on the base of the

sander for this purpose.

1. Place the sander on a surface that is level but also

provides enough room on all sides for the workpiece

and for the operator (or bystanders) to not be

standing in line with the wood while using the tool.

Allow room for the belt to be positioned horizontally

or vertically.

2. The hardware to mount this sander is NOT supplied

with the sander.

ON

OFF

1

4

3

2

3

CAUTION

!

Summary of Contents for PCB420SA

Page 8: ...8 UNPACKING YOUR BELT DISC SANDER ON OFF A D E B F G H C...

Page 22: ...22 NOTES...

Page 23: ...23 NOTES...