14

OPERATION

The belt/disc sander is designed to perform sanding

operations on surface, and edge grain. The sander

will also perform freehand forming and contouring

operations. The following suggestions are recommended

for best results and safest use.

1. Always apply light pressure allowing the abrasive to

remove the material slowly.

2. The workpiece should be moved, continuously, to

avoid burning.

3. Avoid sanding small pieces of wood which will posi-

tion the fingers close to the abrasive belt or disc.

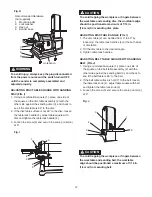

ON/OFF SWITCH (FIG. L)

To avoid injury, always keep the plug disconnected

from the power source and the switch turned OFF

until the sander is completely assembled and

adjusted properly.

The ON/OFF power switch is located on the front of the

sander, and incorporates a removable safety switch (1).

1. To turn the machine “ON”, move the switch up to the

“ON” position.

2. To turn the machine “OFF”, move the switch down to

the “OFF” position.

In situations where the sander may be left unattended,

the operator has the option of removing the “black”

safety portion of the ON/OFF switch to render the

sander inoperable. When the operator is ready to use

the machine again, the “black” safety portion of the

switch may be reinstalled simply by inserting it into the

opening in the switch and pushing it in until it “seats.”

Fig. L

CAUTION

!

WARNING

!

ON

OFF

REMOVE

TO LOCK

1

BELT HORIZONTAL SANDING (FIG. M)

To avoid trapping the workpiece or fingers between

the worktable and sanding belt, the worktable

edge should be positioned a maximum of 1/16 in.

(1.6 mm) from sanding belt.

When using the sanding belt in the horizontal position,

to perform surface or edge sanding, the belt worktable

(1) must always be used. Always hold the workpiece

(2) firmly keeping your fingers away from the sanding

belt . Always keep the end of the workpiece against the

belt worktable (1) and move the work evenly across the

sanding belt. Apply only enough pressure to allow the

sanding belt to remove material. Use extra caution when

sanding very thin pieces.

Fig. M

SANDING INSIDE CURVES (FIG. N)

To avoid injury, do not apply the end of the

workpiece to the idler drum (1). This could cause the

workpiece to fly up or cause kickback.

With care, freehand sanding of inside curves can be

accomplished on the idler drum (1). Never attempt to

sand the ends of a workpiece on the idler drum (1).

Fig. N

CAUTION

!

1 2

3

CAUTION

!

1

Summary of Contents for PCB420SA

Page 8: ...8 UNPACKING YOUR BELT DISC SANDER ON OFF A D E B F G H C...

Page 22: ...22 NOTES...

Page 23: ...23 NOTES...