16

MAINTENANCE

•

For your safety, turn switch OFF and remove

the power cord from the electrical outlet before

adjusting or performing maintenance on your

sander.

•

To avoid electric shock or fi re, all repairs to

the electrical components should be done by

a qualifi ed service technician. Before each use

check for damaged, missing, or worn parts;

check for alignment of moving parts, binding,

improper mounting, or any other conditions

that may affect the operation. Should any of

these conditions exist, do not use the sander

until properly repaired or parts are replaced.

Frequently blow or vacuum dust from all sander

parts and motor housing.

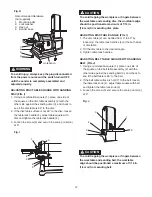

REPLACING SANDING DISC (FIG. S, T)

To avoid injury, turn switch OFF and disconnect the

plug from the power source before removing and

installing sanding belt.

A sanding disc is pre-mounted at the factory. Use

only sanding discs that measures 8 in. (203 mm) in

diameter.

1. Remove the disc worktable (See Fig. A on page 10),

and then remove the disc cover (1) by removing six

screws (2).

2. Remove the existing disc, and clean any residue left

on disc plate (3). Only use mineral spirits to remove

this residue.

Fig. S

3. Peel the plastic (4) back from new sanding disc (5)

and carefully press sanding disc fi rmly in position

around the sanding plate. Make sure the disc is

centered on the plate.

4. Reinstall the disc cover, tighten screws and place

sanding table back on unit.

Fig. T

WARNING

!

ON

OFF

1

2

3

5

4

REPLACING SANDING BELT (FIG. U, V)

To avoid injury, turn switch OFF and disconnect the

plug from the power source before removing and

installing sanding belt.

Use only sanding belts that measures 4 in.

(102 mm) in width / 36 in. (914 mm) in length.

1. Remove the belt worktable. (See Fig. D on page 10)

2. Position the belt work support frame horizontally

as shown in Fig. U. Loosen the inner hex

screw (1) using a 5 mm hex wrench, turning it

counterclockwise. Do not remove the screw.

3. Remove the two screws (2, 3) using a phillips head

screwdriver, and pull out the tension lever (4) to

release the tension of the sanding belt (5). Remove

the belt exhaust cover (6).

4. Remove the sanding belt (5) from both sanding

drums (7).

5. Place new sanding belt over sanding drums. Make

sure the belt arrow located on the inside of the belt is

pointed in the right direction.

6. Replace the belt exhaust cover (6) in position.

NOTE:

Stretch the belt from the right side to make

top and lower side of the belt fl at and tight as shown

in Fig. V for keeping the belt exhaust cover (6) away

from interferring with the sanding belt when placing

the belt exhaust cover on.

7. Replace and tighten the two screws (2, 3) and push

the tension lever (4) in to apply belt tension.

8. Push the belt by hand and check if the sanding belt

tends running to one side or the other of the two

drums.

9. View from the switch end of sander, if the sanding

belt runs toward disc, slightly turn the tracking knob

(8) clockwise (down).

10. View from the switch end of sander, if the sanding

belt runs away from the disc, slightly turn the

tracking knob (8) counterclockwise (up).

11. Plug in the sander and turn the switch ON and OFF

quickly to check if the sanding belt moves to either

side. Re-adjust and fi ne-tune the tracking knob if

necessary.

WARNING

!

WARNING

!

Summary of Contents for PCB420SA

Page 8: ...8 UNPACKING YOUR BELT DISC SANDER ON OFF A D E B F G H C...

Page 22: ...22 NOTES...

Page 23: ...23 NOTES...