9 - ENG

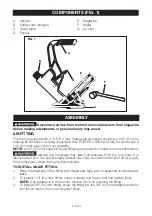

3 . Position the tool on the tongued edge of the flooring strip aligning the driver guide (C)

against the front of the flooring strip .

4 . Strike the rubber cap (B) with the rubber end of the mallet (F) . The tool will then drive

the cleat/staple at the correct 45 degree angle .The proper length of flooring cleat to use

with various thicknesses of flooring . Repeat this process until the job is completed .

COLD WEATHER OPERATION

When operating tools at temperatures below freezing:

1 . Make sure compressor tanks have been properly drained prior to use .

2 . Keep tool as warm as possible prior to use .

3 . Make certain all fasteners have been removed from magazine .

4 . Put 5 to 7 drops of PORTER-CABLE pneumatic tool oil in the air inlet .

5 . Lower air pressure to 80 psi (5 .5 bar) or less .

6 . Load nails into magazine and reconnect air .

7 . Actuate the tool 5 or 6 times into scrap lumber to lubricate O-rings .

8 . Turn pressure up to operating level (not to exceed 120 psi) and use tool as normal .

9 . Re-lubricate at least once daily .

10 . Always drain the compressor tanks at least once a day .

HOT WEATHER OPERATION

Tool should operate normally . However, keep tool out of direct sunlight as excessive heat

can deteriorate bumpers, O-rings and other rubber parts resulting in increased maintenance .

MAINTENANCE

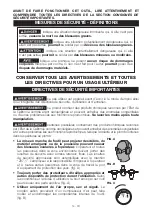

To reduce the risk of personal injury, disconnect tool from air

supply before performing maintenance, clearing a jammed fastener, leaving work

area, moving tool to another location or handing the tool to another person.

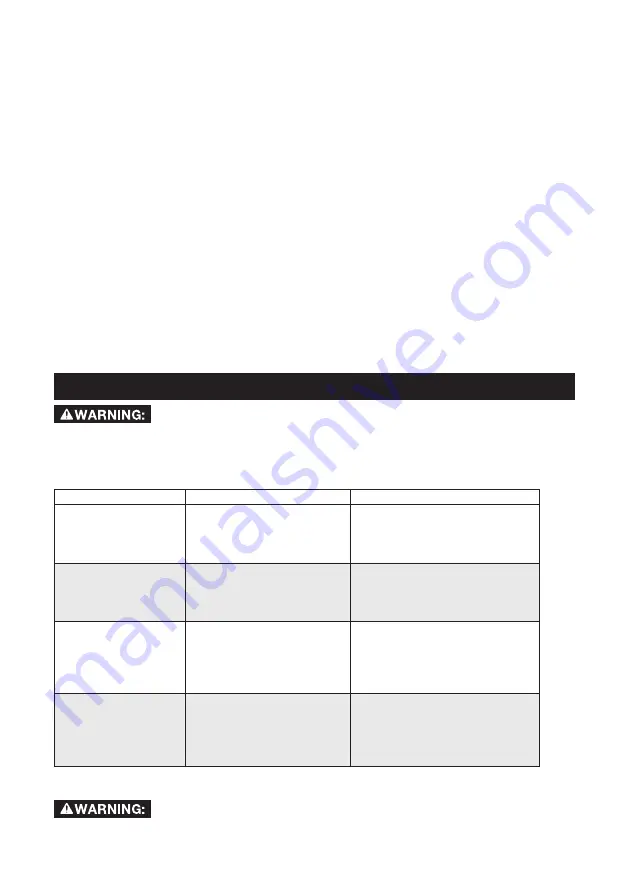

DAILY MAINTENANCE CHART

ACTION

WHY

HOW

Lubricate tool

with 5-7 drops of

PORTER-CABLE

Pneumatic Tool Oil

Prevents failure of o-rings

Insert drops into air fitting

on end cap of tool

Drain compressor

tanks and hoses daily

Prevents accumulation

of moisture in

compressor and nailer

Open petcocks or other

drain valves on compressor

tanks . Allow any accumulated

water to drain from hoses

Clean magazine,

magazine release

and contact trip

mechanism .

Permits smooth operation

of magazine, reduces

wear and prevents jams .

Blow clean with compressor

air . The use of oils, lubricants

periodically or solvents is

not recommended as they

tend to attract debris .

Before each use,

check to insure all

screws, nuts and

fasteners are tight

and undamaged .

Prevents jams, leaks

and premature failure

of tool parts .

Tighten loose screws or other

fasteners using the appropriate

hex wrench or screwdriver .

CLEANING

When cleaning, use only mild soap and a damp cloth on plastic parts . Many

household cleaners contain chemicals which could seriously damage plastic . Also, do not use