10

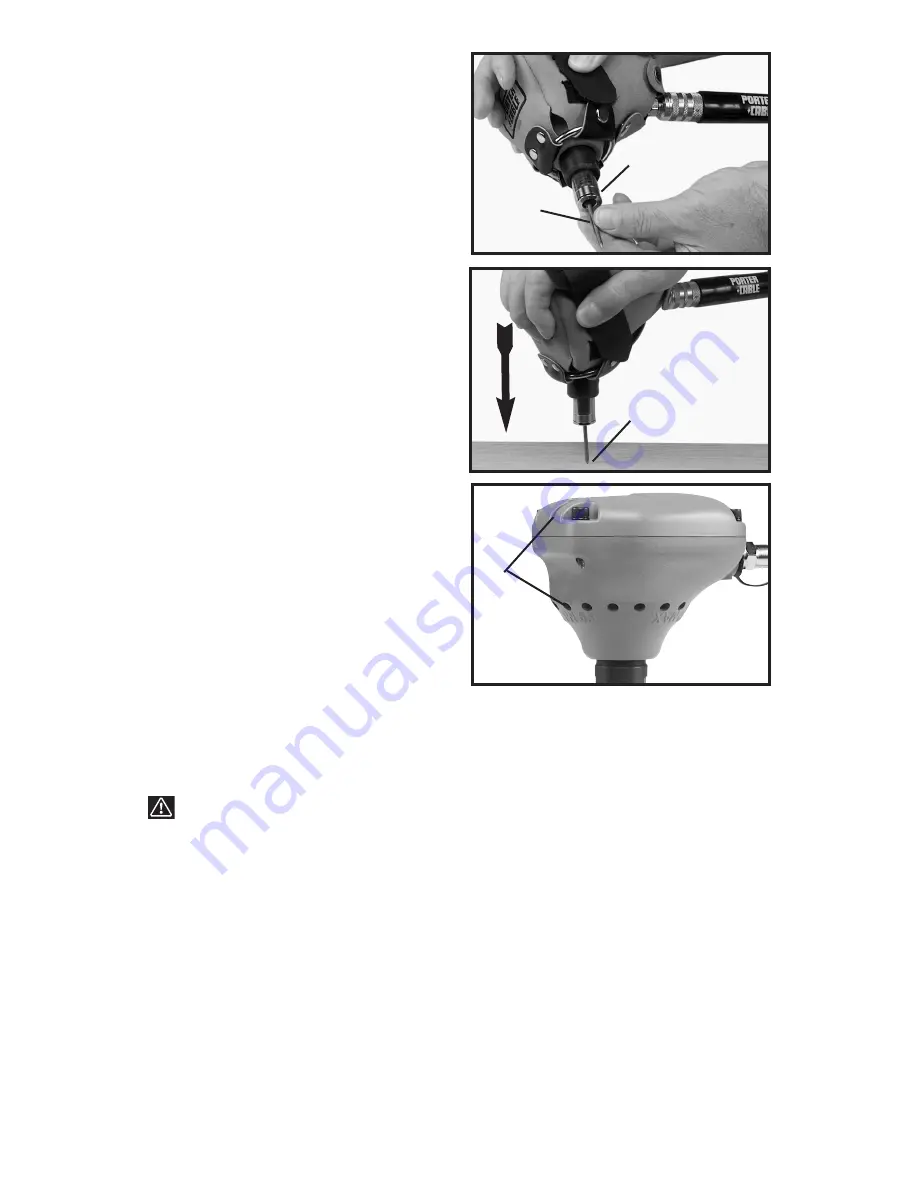

1. Attach appropriate nail guide or

hammer attachment.

2. Orient nail (A) Fig. 29 with point

down and and insert into the nail

guide (B).

3. Position point of nail (A) Fig. 30 in

the desired location and push down

on the tool. The tool will began

cycling and driving the fastener.

NOTE:

Be sure to maintain constant

hand pressure in line with the nail until

the nail is fully seated. Experiment

with the air pressure setting to

determine the lowest setting that will

consistently perform the job at hand.

Air pressure in excess of that required

can cause premature wear and/or

damage to the tool.

4. During each tool cycle, air will

exhaust out of ports (A) Fig. 31.

5. When using hammer attachment,

hold fastener by hand until driven

deep enough to stay in place.

Remove hand to complete driving

fastener.

MAINTENANCE

CLEAN AND INSPECT DAILY

WARNING:

Disconnect tool from air supply before cleaning and

inspection. Correct all problems before placing the tool back in use.

Wipe tool clean and inspect for wear or damage. Use non-flammable

cleaning solutions to wipe exterior of tool only if necessary. DO NOT SOAK

tool with cleaning solutions. Such solutions can damage internal parts.

Keep all screws as well as nail guide bushing tight. A 4mm hex wrench and 24

x 30mm open end wrenches are provided. Loose screws and bushings can

cause personal injury or damage tool.

If tool is used without an in-line oiler, place 5 or 6 drops of Porter-Cable Air

Tool Oil into the air inlet of the tool at the beginning of each workday.

SERVICE AND REPAIRS

All quality tools will eventually require servicing or replacement of parts due

to wear from normal use. These operations should ONLY be performed by

either an AUTHORIZED PORTER-CABLE SERVICE STATION or a PORTER-

Fig. 30

A

Fig. 29

A

B

A

Fig. 31