7

FINISH NAIL GUIDE ASSEMBLY

1.

WARNING:

Disconnect tool from air supply.

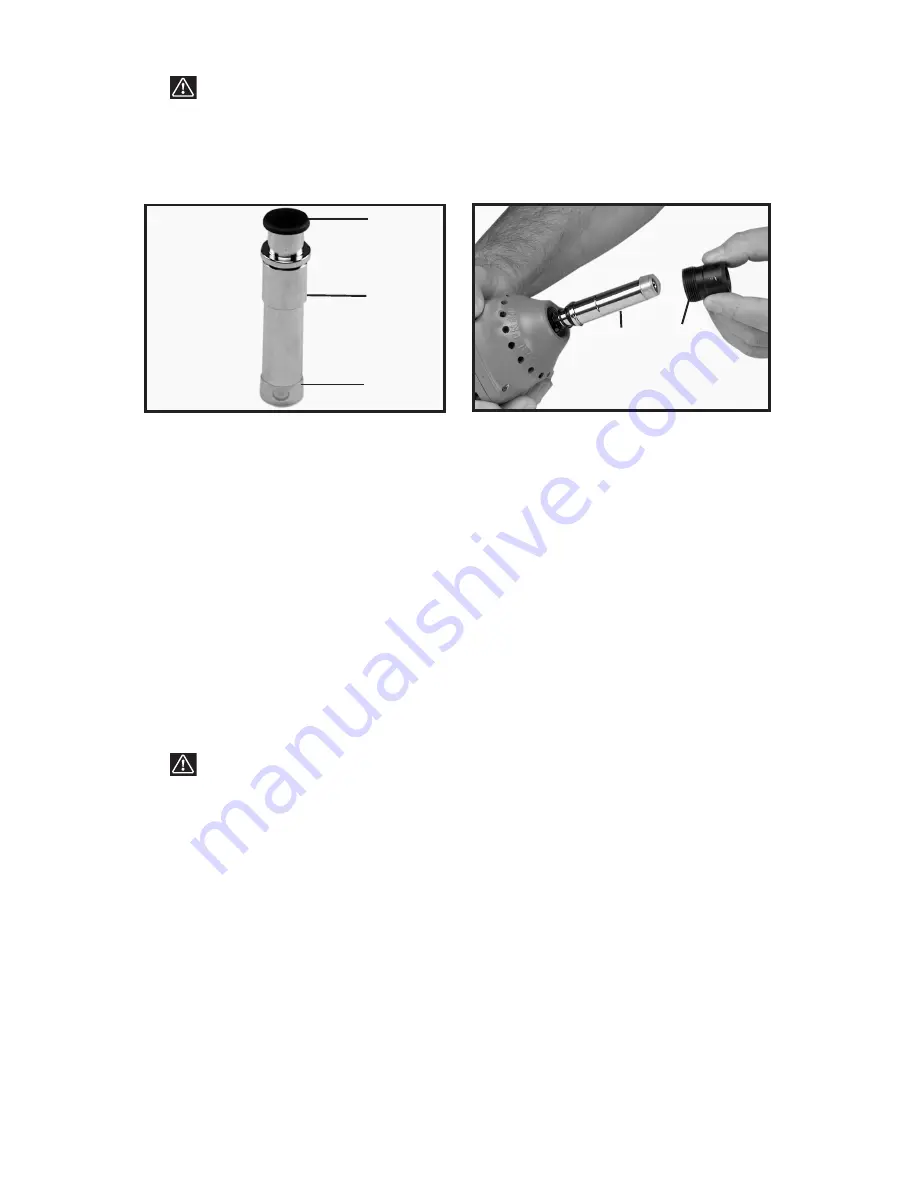

2. The finish nail guide (A) Fig. 17, for driving 1-

1

/

4

"(3d) to 2-

1

/

2

"(8d) finish

nails, is provided with a rubber nose cushion (B) Fig. 17 that will reduce

marring of the work surface. Assembly of the finish nail guide requires the

use of the magnetic nail guide bushing supplied on the tool (Fig. 15).

3 To install finish nail guide, lay tool on its cap with nail guide pointing

upward. Loosen and remove the magnetic nail guide bushing (B) Fig. 15

using the 24mm open end wrench supplied.

4. Lift the magnetic nail guide (A) Fig. 15 off of the driver blade and place it in

the carrying case.

5. Remove the plastic plug (C) Fig. 17 from the finish nail guide. Take care

not to allow the drive pin and spring to fall out of the bore of the finish nail

guide. Slide the finish nail guide (A) Fig. 18 over the driver blade.

6. Slide the magnetic nail guide bushing (B) Fig. 18 over the finish nail guide

and screw it into the housing using the 24mm open end wrench and tighten

as securely as possible.

STANDARD NAIL GUIDE ASSEMBLY

1.

WARNING:

Disconnect tool from air supply.

2. Standard (spike) nail guide has a ¾" ID and is used for driving large 4"

(20d) to 6-

1

/

2

" (70d) common nails/spikes.

3. To install standard (spike) nail guide and bushing, lay tool on its cap with

nail guide pointing upward. Loosen and remove the magnetic nail guide

bushing (B) Fig. 15 using the 24mm open end wrench supplied.

4. Slide the magnetic nail guide (A) Fig. 15 off of the driver blade.

5. Place both the magnetic nail guide and bushing in the carrying case for

safe storage.

6. Take the standard nail guide (A) Fig. 19 and guide bushing (B) from the

carrying case.

7. Slide the standard nail guide (A) Fig. 20 over the driver blade and inside of

the spring coils. Slide the standard nail guide bushing (B) over the driver

blade and spring. Screw the standard nail guide bushing into the tool

housing and tighten as securely as possible using the 24mm open end

wrench.

Fig. 17

A

B

C

Fig. 18

A

B