Before each use:

●

Drain water from air compressor tank and condensation from air lines. See air compressor’s

operators manual.

Disconnect the tool from the air supply before lubricating or changing

abrasive disc.

●

Lubricate tool, see “Maintenance” section in this manual.

●

Place abrasive disc onto sander pad. See "To Install Abrasive Disc" paragraph in the

"Maintenance" section.

●

Connect tool to air hose of recommended size.

NOTE:

The use of a quick connect set makes

connecting easier.

IMPORTANT: The use of air filters and air line lubricators is recommended.

To use:

●

Turn air compressor on and allow air tank

to fill.

●

Set the air compressor’s regulator to 90

PSI. This tool operates at a maximum

90

PSI

pressure.

●

Depress trigger to operate tool.

●

Release trigger to stop tool.

●

This tool is equipped with an air valve

control lever to adjust RPM speed from

0-12000. It is recommended to operate the

tool with the air valve control at the

maximum setting for the best tool

performance.

●

When job is complete, turn the air

compressor off and store as described in

the air compressor operator manual.

Tips

●

Begin sanding with an abrasive grit sandpaper

coarse enough to remove the high spots.

Progress to a finer grit sandpaper until the

desired finish is obtained.

●

Never change from coarse grit sandpaper to

a very fine grit sandpaper, always progress

gradually to the finer grit.

6- ENG

D29847

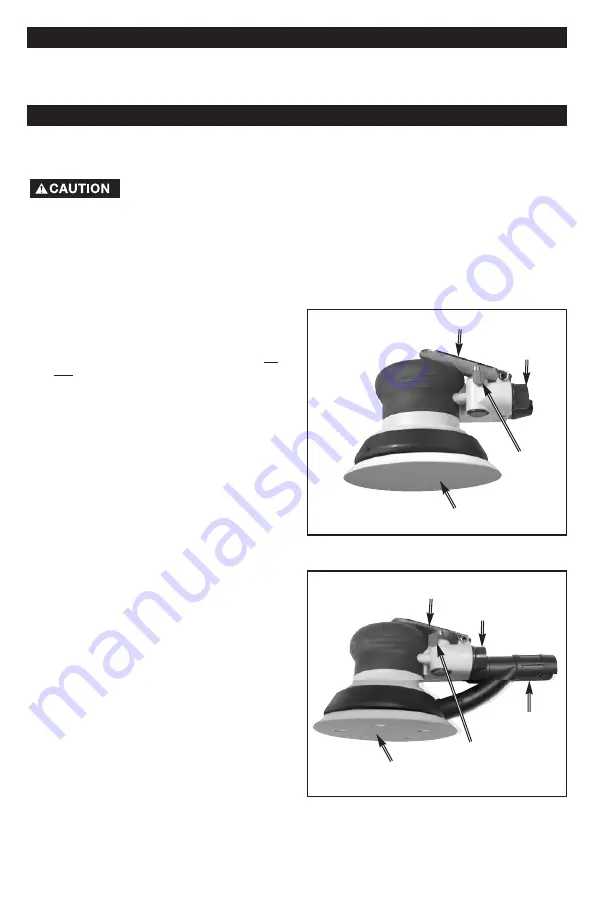

Air Inlet

Trigger

Sander Pad

Air Valve

Control

Lever

ASSEMBLY

IMPORTANT:

Line pressure or hose inside diameter should be increased to compensate for

unusually long air hoses (over 25 feet). Minimum hose diameter should be 3/8” I.D. and fittings

should have 1/4” NPT thread.

OPERATION

Air Inlet

Trigger

Sander Pad

Air Valve

Control

Lever

Vacuum

Exhaust

Without Vacuum Option

With Vacuum Option

Summary of Contents for PTS10

Page 9: ...9 ENG D29847 NOTES...