6- ENG

BASIC AIR COMPRESSOR COMPONENTS

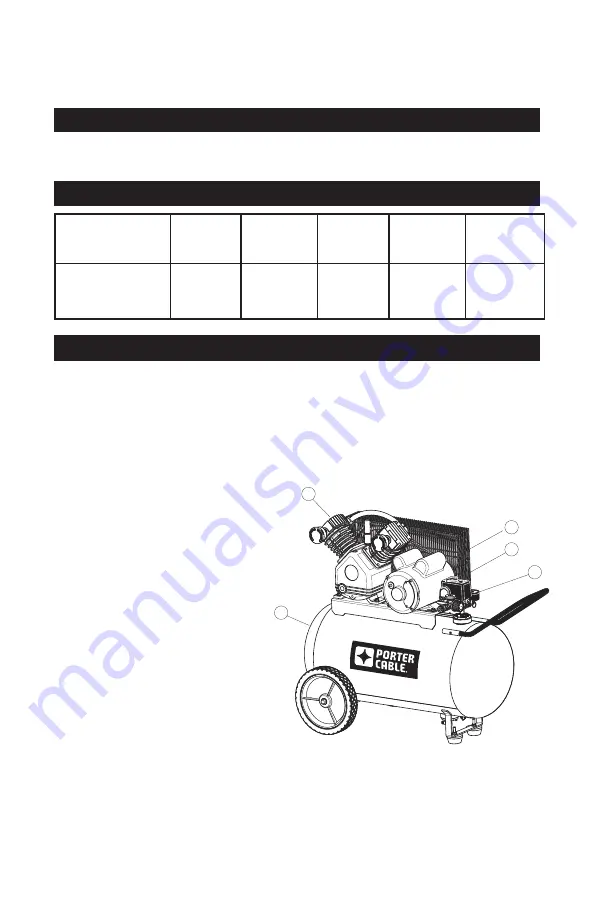

The basic components of the air compressor are the electric motor, pump,

pressure switch and tank (see

Fig. 1

).

The

electric motor

(see

A

) powers the pump. The electric motor is equipped

with an

overload protector

to help prevent possible motor burnout. If the motor

becomes overheated, the overload protector will shut it down. Should this

occur, allow the motor to cool for 10-15 minutes, then press (never force) the

motor reset switch to restart the motor.

The

pump

(see

B

) compresses the

air and discharges it into the tank.

The

tank

(see

C

) stores the

compressed air.

The

pressure switch

(see

D

) shuts

down the motor and relieves air

pressure in the pump and transfer

tube when the air pressure in the

tank reaches the kick–out pressure.

As compressed air is used and

the pressure level in the tank

drops to the kick–in pressure, the

pressure switch restarts the motor

automatically, without warning and

the pump resumes compressing air.

The

air line outlet

(see

E

). Connect 1/4” NPT air hose to this outlet.

Fig. 1

WARNING

SPECIFICATION CHART

CALIFORNIA PROPOSITION 65 WARNING:

This product contains chemicals

known to the State of California to cause cancer, birth defects and/or

reproductive harm.

MODEL NO.

RUNNING

H.P.

TANK

CAPACITY

GALLONS

VOLTAGE/

AMPS/

PHASE

KICK-IN

PRESSURE

KICK-OUT

PRESSURE

PXCM201

1.6

20 (75,7)

120

15

1

105

(7,24 bar)

135

(9,31 bar)

6. Protect the air hose from damage and puncture. Inspect it weekly for weak or worn

spots, and replace it if necessary.

7. To reduce the risk of electric shock, do not the unit expose to rain. Store it indoors.

A

B

C

D

E

Summary of Contents for PXCM201

Page 12: ...13 ENG A Full B Add Fig 6 OPEN CLOSE F...

Page 27: ...NOTES...