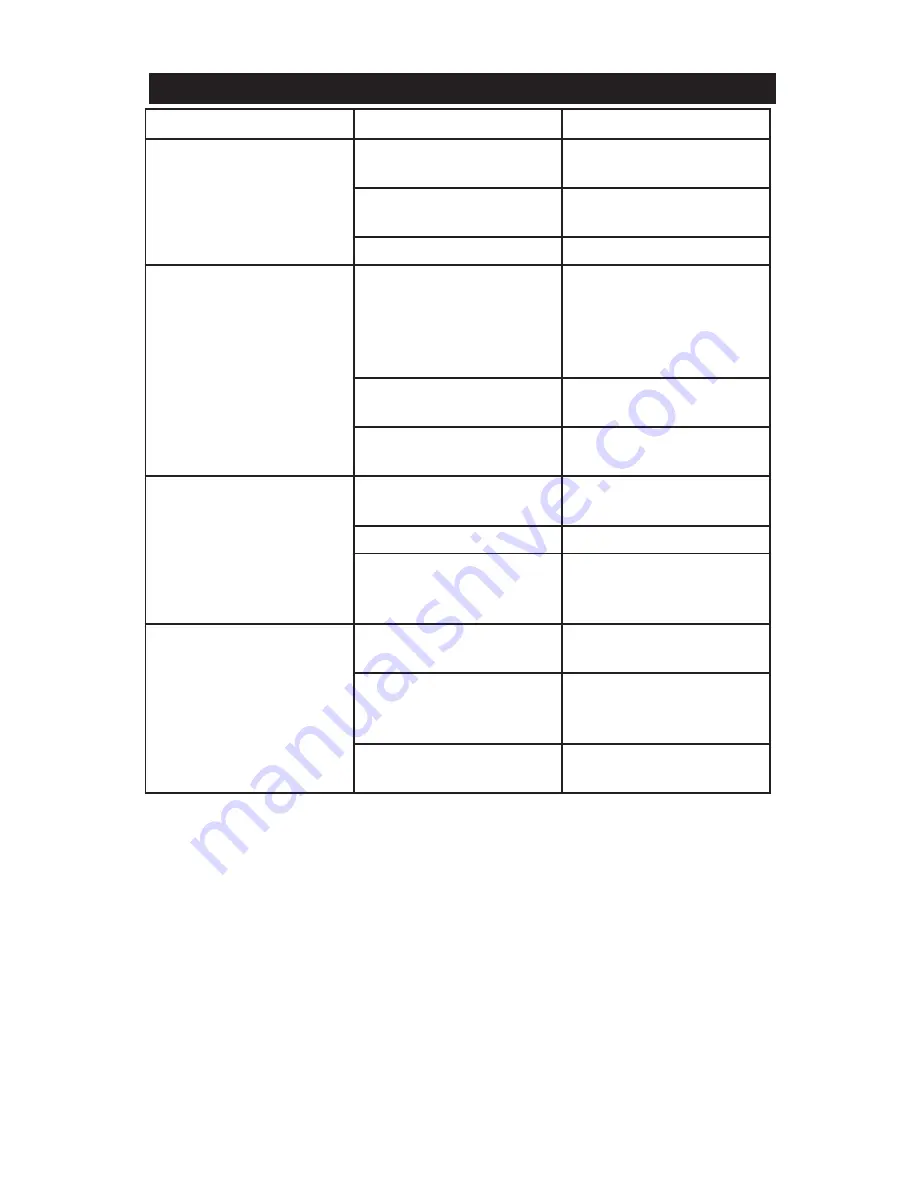

20- ENG

PROBLEM

POSSIBLE CAUSE

SOLUTION

Oil in discharge air

Worn piston rings or

cylinder

Contact authorized

service center.

Restricted air intake

Clean or replace the air

filter element(s).

Oil level too high

Reduce to proper level.

Overheating

Poor ventilation

Relocate compressor to

an area with cool, dry,

well circulated air, at

least 12 in. from nearest

wall.

Dirty cooling surfaces

Clean all cooling

surfaces thoroughly.

Restricted air passages

Replace transfer tubes

and/or unloader.

Excessive belt wear

Pulley out of alignment

Realign pulley with

compressor flywheel.

Improper belt tension

Readjust.

Pulley wobbles

Replace the pulley and

check for a damaged

crankshaft or flywheel.

Compressor

won’t start in cold

temperatures

Too much back pressure

in tank

Open petcock when

starting motor.

40W oil in crankcase

Use synthetic blend,

nondetergent

air compressor oil.

Compressor too cold

Move compressor to a

warmer location.

TROUBLESHOOTING

Summary of Contents for PXCMLC3706056

Page 13: ...13 ENG OPEN CLOSE F E Fig 6 ...