Flange Machine

Part Number 6Z8303

Installation and Setup

15

Figure 3.4

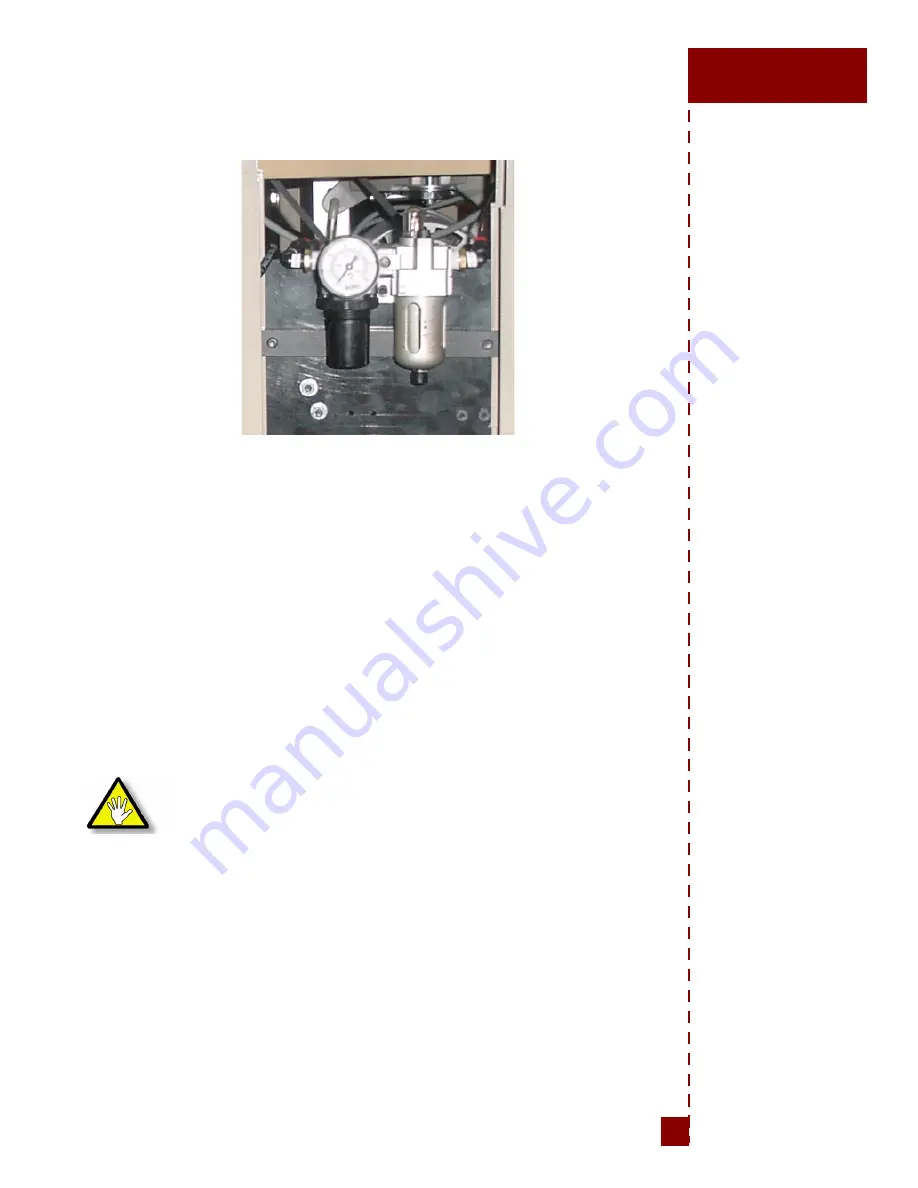

Filling the linkage oil reservoir

Threading the Sewing Head

The factory threads the sewing head prior to shipping. However, the machine

requires additional threading. To complete the threading process:

1

Tie the ends of the threads in the machine head with the ends of the threads

from the thread spools.

2

Pull the threads through, making sure the knots will go through the looper

eyes.

3

After the new threads from the spools come to the needle eyes, trim the

knots off.

4

Continue threading each needle by hand. For further detail, see

.

Grounding the PFM-4000 Flange Machine

NEC

®

National Electric

Code; establishes

requirements for electrical

wiring and equipment.

Before connecting the power source, you must properly ground the flange

machine. To do this, identify the single ground wire leading from the

synchronizer, which is located on the right side of the sewing head. Attach the

ground wire to the sewing head. For more information regarding proper

grounding and wiring, refer to NEC

®

and local codes.

CAUTION:

Do not try to pass the thread knots through the eyes of the

needles. This could cause the needles to bend.

linkage lubricator

oil reservoir

regulator