Flange Machine

Part Number 6Z8303

Sewing Adjustments

35

Needles

The PFM-4000 Flange Machine typically has two needles, the overedge (right-

hand) needle and the safety stitch (left-hand) needle. Unless otherwise specified

when purchased, the spare parts kit includes a packet of 135 x 7 #24 needles.

Always use quality needles for flanging.

Burr

A rough, metal edge,

usually in the eye of a

needle.

Always verify the condition of the needle. Look at the point of the needle to

determine if the end is sharp or broken. You will not see the exact point on a sharp

needle. If the point appears to shine, the needle is probably blunt or damaged. To

test for burrs within the needle eye:

1

Thread the needle.

2

Slide the thread back and forth along all inside edges of the eye. The thread

should move smoothly.

3

Select another needle if the thread snags or frays.

See

to learn how to properly handle and dispose of needles.

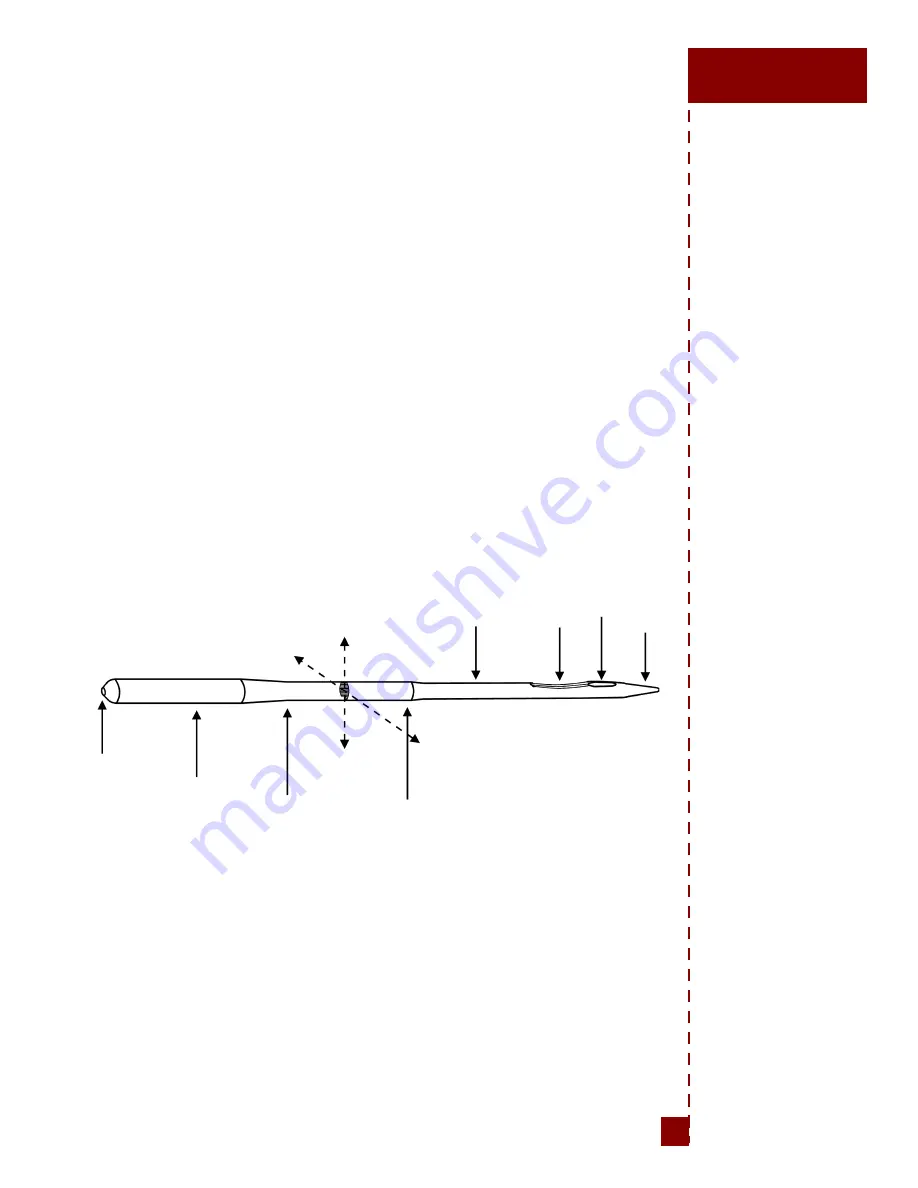

details the specific parts of the needle. Become familiar with these parts.

Always verify the condition of the needle before sewing.

Figure 6.2

Parts of a needle

Loopers and Needle Guards

Timing

A procedure to

ensure synchronization of

moving parts.

The looper’s function is to catch the thread loop created by the needle and to

bring the bottom thread into the thread triangle. The looper and the needle work

together to form the chain stitch. It is very important that the looper and its

related parts are synchronized. These specific timing procedures are discussed in

Butt

Shank

Cone

Front

Reinforced blade

Right

Left

Back

Blade

Scarf

Eye Point