5

ASSEMBLY

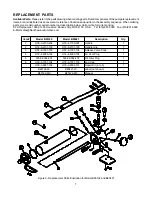

Little, if any, assembly is required of this device. Always secure threaded connections with pipe thread compound.

Tighten securely to prevent accidental removal of components while in use. Familiarize yourself with the specifications

and illustrations in this owner's manual. Know your pump, its limitations and how it operates before attempting to use.

Refer to Specification chart on page 3 for details of oil port thread size, usable oil capacity, and more.

OPERATION

1. Connect to suitable application.

2. Operate pump until desired pressure, load or position is reached. Always monitor pressure, load or position using

suitable equipment. Pressure may be monitored by means of an optional manifold and gauge (contact

Porto-Power

Blackhawk Automotive

). Load may be monitored by means of a load cell and digital indicator. Correct application

position can only be determined by the operator of the equipment.

3. Turn the release valve knob slowly counterclockwise (never more than 2 full turns) to retract application.

MAINTENANCE

1. Inspect hoses and connections daily. Replace damaged components immediately with Porto-Power Blackhawk

replacement parts only.

2. Tighten connections as needed. Use non-hardening pipe thread compound when servicing connections.

3. Use only good quality hydraulic fluid. We recommend Hein-Werner HW93291 or equivalent.

Note:

Use only good quality hydraulic oil.

Never

use brake fluid, transmission fluid, turbine oil, motor oil, alcohol,

glycerin etc. Use of other than good quality hydraulic oil will void warranty and damage the pump, hose, and application.

Adding Hydraulic Fluid

1. Depressurize and disconnect hydraulic hose from application.

2. With pump in its upright, horizontal position, remove the air vent plug located on the top plate of the reservoir.

3. Use a small funnel to fill reservoir to within 1/4" (6mm) of the hole opening.

4. Wipe up any spilled fluid and reinstall the air vent plug.

Changing Hydraulic Fluid

For best results, change fluid once a year.

1. Remove the air vent plug from pump reservoir as above.

2. Lay the pump on its side and drain the fluid into a suitable container.

Note:

Dispose of fluid in accordance with local regulations.

3. Set pump in its level upright position.

4. Fill with good quality hydraulic oil to within 1/4" (6 mm) of the hole opening.

5. Reinstall air vent plug.

Lubrication

Use a light machine oil to lubricate pivot points, hinges etc.

NOTE:

Never operate pump with release valve closed and disconnected from application. If operated in this condition,

the hose and connections become pressurized. This increases burst hazard. Damage may occur to pump and its

components.

Storage

1. When not in use, depressurize and disconnect hydraulic hoses from application.

2. Wipe clean, thoroughly.

3. Store in clean, dry environment. Avoid extreme temperatures.

4. Lock handle into position using the spring loaded locking pin mechanism.

5. Shield pump with a protective cover.

Summary of Contents for B65122

Page 8: ...memo ...