En

vir

onm

entally Friendly Technolo

gy

Page 21

Service and Inspection

Hydraulic system

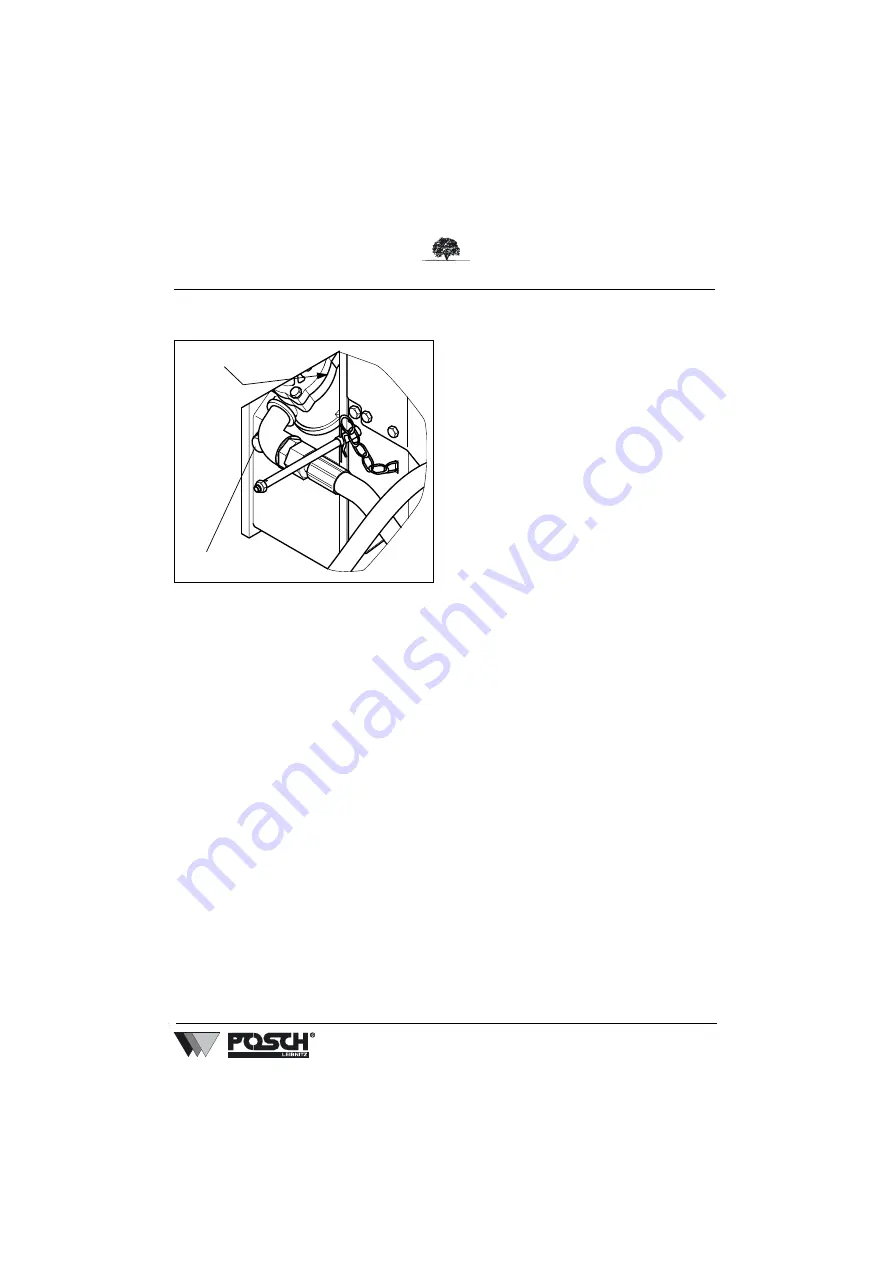

Fig. 20 - Checking the oil level

Note:

`ÜÉÅâ= çáä= äÉîÉä= ïÜÉå= éêÉëëìêÉ

éä~íÉ=áë=êÉíê~ÅíÉÇK

tÜÉå= íÜÉ= çáä= äÉîÉä= Ö~ìÖÉ= áë= Ñìää= íÜáë

ÅçêêÉëéçåÇë=íç=íÜÉ=

maximum oil level

K

fÑ=íÜÉ=çáä=äÉîÉä=áë=áå=íÜÉ=ãáÇÇäÉ=çÑ=íÜÉ

çáä= äÉîÉä= Ö~ìÖÉ= íÜáë= ÅçêêÉëéçåÇë= íç= íÜÉ

minimum oil level.

√

få=íÜáë=Å~ëÉ=áããÉÇá~íÉäó=êÉÑáää=ïáíÜ

ÜóÇê~ìäáÅ=çáä>

cáää= ÜóÇê~ìäáÅ= çáä= ~í= çáä= ÑáäíÉê= ~ÑíÉê

êÉãçîáåÖ=çáä=ÑáäíÉê=ÅçîÉê=EëÉÉ=cáÖK=ON =

Safety Switch

`ÜÉÅâ=äáåâë=çÑ=ë~ÑÉíó=Åçåíêçä=ÉäÉãÉåí

Ñçê= É~ëÉ= çÑ= çéÉê~íáçå= ~åÇ= äìÄêáÅ~íÉ= áÑ

åÉÅÉëë~êóK

`ÜÉÅâ=ÑêÉÉ=êçÅâÉê=ãçîÉãÉåíK

Servicing

Oil change of hydraulic system

Caution!

aáëéçëÉ= çÑ= ìëÉÇ= çáä= áå

~ÅÅçêÇ~åÅÉ= ïáíÜ=

environmental regulations

K

`ÜÉÅâ=äÉÖ~ä=ÉåîáêçåãÉåí~ä=êÉÖìä~íáçåëK

Note:

oÉíê~Åí= éêÉëëìêÉ= éä~íÉ= ÄÉÑçêÉ= çáä

ÅÜ~åÖÉK

qÜÉ=Ñáêëí=çáä=ÅÜ~åÖÉ=ëÜçìäÇ=ÄÉ=Å~êêáÉÇ

çìí=~ÑíÉê=RMM=íç=TMM=çéÉê~íáåÖ=Üçìêë=çê

~ÑíÉê=~=óÉ~êK=

`~êêó= çìí= ÑìêíÜÉê= çáä= ÅÜ~åÖÉë= ~í= äÉ~ëí

çåÅÉ=~=óÉ~êK

1.

léÉå= çáä= ÑáäíÉê= äáÇ= ~åÇ= í~âÉ= çìí= íÜÉ

ÑáäíÉê=Å~êíêáÇÖÉK

2.

léÉå=íÜÉ=çáä=Çê~áå=éäìÖK=

√

qÜÉ=çáä=Çê~áå=éäìÖ=áë=äçÅ~íÉÇ=~í=íÜÉ

Äçííçã= çÑ= íÜÉ= çáä= í~åâ= EëÉÉ= cáÖK= N =

Capacity of hydraulic system:

√

RM=äáíÉê

Oil level gauge

Ventilation screw