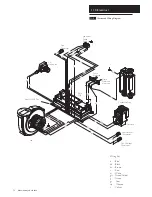

8.0 Flue Options

24

© Baxi Heating UK Ltd 2009

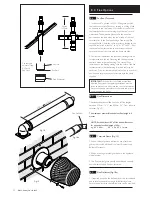

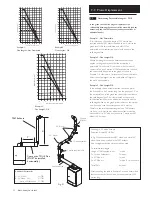

8.6

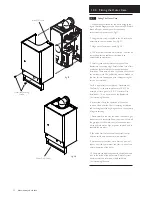

For Roof Terminals

1. In the case of a pitched roof 25 - 50 degrees, position

the lead tile to replace/flash over existing roof tiling. Make

an aperture in the roof suitable for the lower tube of the

roof terminal and ensure the integrity of the roof cover is

maintained. The adjustable plastic collar can either be

positioned on the lead tile or the lower tube of the roof

terminal prior to the final positioning of the vertical flue

through the tile. Check the collar is correctly located to suit

required roof pitch (either 25° to 38° or 37° to 50°). From

inside the roof adjust the flue to a vertical position and

secure to the roof structure with the clamp supplied.

2. For flat roof installations the aluminium flashing must be

incorporated into the roof covering and the appropriate

aperture made in the roof decking. The vertical flue is

lowered onto the flashing making sure the collar of the flue

locates securely with the flashing. (A mastic seal may be

necessary). From inside the roof, adjust the flue to a vertical

position and secure to the roof structure with the clamp

supplied.

IMPORTANT:

If the boiler is not fitted immediately

after the flue system, temporary precautions must be

taken to prevent rain entry into the room of installation.

Any precautionary measures must be removed prior to

commissioning the boiler.

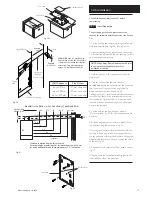

8.7

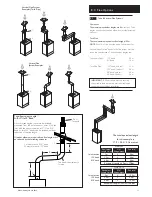

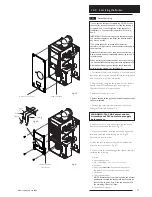

Flue Dimensions

The standard horizontal flue kit allows for flue lengths

between 270mm (10

5

/

8

”) and 800mm (32”) from elbow to

terminal (Fig. 18).

The maximum permissible equivalent flue length is: 4

metres

.

NOTE: Each additional 45° of flue bend will account

for an equivalent flue length of 0.5m.

eg. 45° = 0.5m, 90° = 2 x 45° = 1m etc.

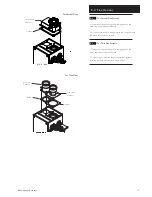

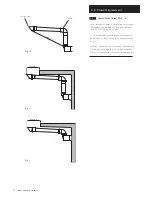

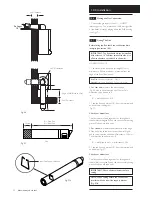

8.8

Terminal Guard (Fig. 19)

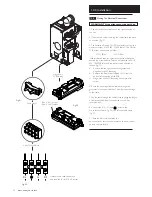

1. When codes of practice dictate the use of terminal

guards, they can be obtained from most Plumbers’ and

Builders’ Merchants.

2. When ordering a terminal guard, quote the appliance

model number.

3. The flue terminal guard should be positioned centrally

over the terminal and fixed as illustrated.

8.9

Flue Deflector (Fig. 18a)

1. If required, push the flue deflector over the terminal end

and rotate to the optimum angle for deflecting plume.

Secure the deflector to the terminal with screws provided.

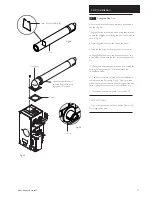

Fig. 18

Fig. 19

270mm

800mm

Push Fit Adaptor

Air Duct

Flue Duct

Cut the same

amount off the

Air Duct &

Flue Duct

Approx

1425mm

Flue Deflector

Fig. 18a