10.0 Installation

29

© Baxi Heating UK Ltd 2009

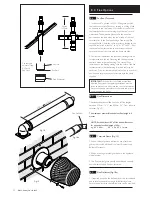

Check Site Requirements (section 7) before

commencing.

10.1

Initial Preparation

The gas supply, gas type and pressure must be

checked for suitability before connection (see Section

7.4).

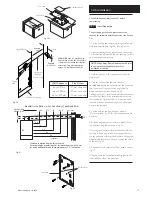

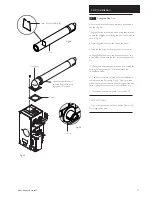

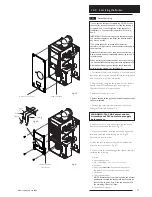

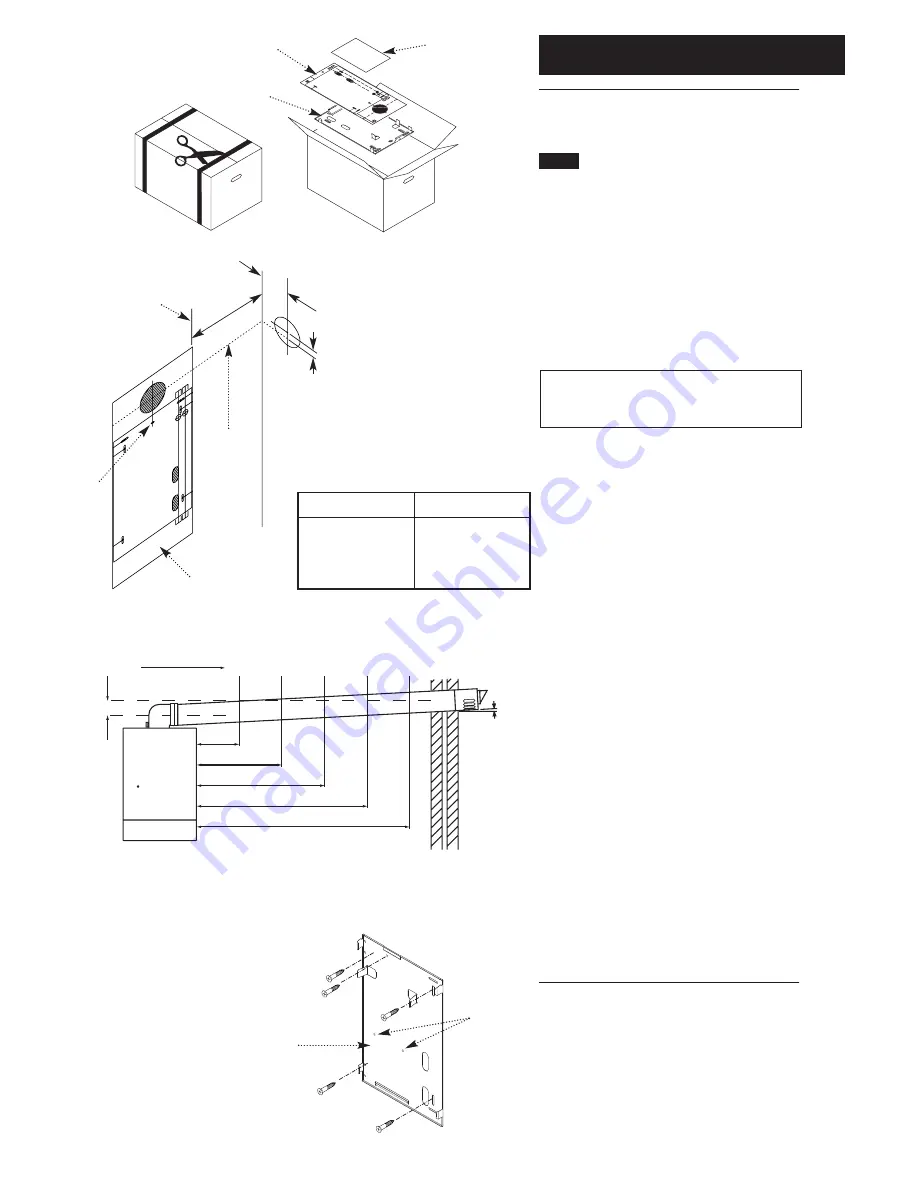

1. Cut the banding and remove the fixing template, wall

plate and literature pack (Fig. 19a) from the carton.

2. After considering the site requirements (see Section

7.0) position the template on the wall ensuring it is level

both horizontally and vertically.

NOTE: When fitting Plume Displacement Kit refer

to the instructions supplied for details of

installation of the flue.

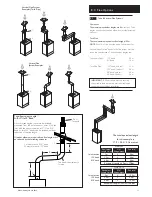

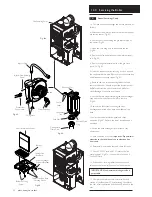

3. Mark the position of the centre hole for the wall

plate (Fig. 20).

4. Mark the centre of the flue hole (rear exit).

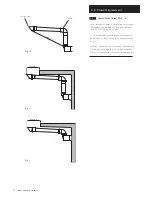

For side exit:

project the horizontal side flue centre line

into the corner of the room and along the wall to

where the flue hole will be drilled. (Fig. 20).

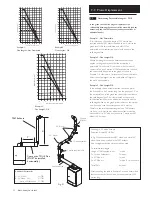

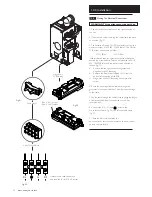

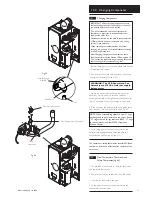

The diagram (Fig. 21) shows the dimensions required to

ensure any horizontal flue is installed with the correct

fall to the boiler. Mark the offset (V) dimension and if

required, mark the position of the gas and water pipes.

Remove the template.

5. Cut the hole for the flue (minimum diameter

127mm, see table (Fig. 20) for wall thicknesses and flue

diameters).

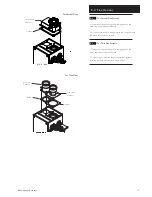

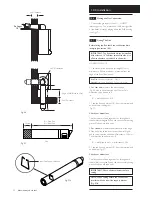

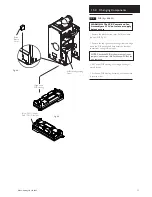

6. Drill and plug the wall as previously marked. Secure

the wall plate using the centre hole (Fig. 22).

7. Ensuring the wall plate is level both horizontally and

vertically, drill and plug at least 4 securing positions at

the top and bottom through the wall plate. Utilising the

slots available ensure the wall plate is square and secure

to the wall (Fig. 22).

8. Additionally drill 2 relief holes 10mm deep in the wall

(Fig. 22).

9. Loosely route the condensate discharge pipe to the

lower left hand side of the wall plate.

Wall Thickness

up to 227mm

up to 750mm

up to 1200mm

Flue Hole ø

127mm core drill

150mm core drill

175mm core drill

Fig. 20

Fig. 21

Fig. 22

Horizontal

Side Flue

Centre Line

EXAMPLE: Boiler is 2 metres away

from corner of wall, flue duct hole is

110mm up from horizontal side flue

centre line. This will maintain the

approx 1.5° backfall to the boiler.

Wall Plate Template

Wall Plate

Edge of Boiler

0.5

1.0

2.0

3.0

4.0

Distance in metres from boiler to the wall.

For pipe lengths greater than 4m increase the off-set by 26mm

for every additional metre to maintain approx 1.5

°

inclination.

V

Flue Duct Hole

Offset V (mm)

13.5

27.5

55

82.5

110

(metres)

(mm)

1.5

°

Backfall to the Boiler, ie. 2m flue offset (V) position 55mm

Example

2m

Example

V = 55mm

125mm

Centre

Hole

Wall Plate

Template

Literature Pack

Fig. 19a

Relief Holes