14.0

Servicing the Boiler

39

© Baxi Heating UK Ltd 2009

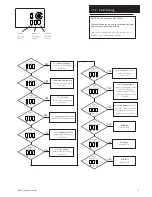

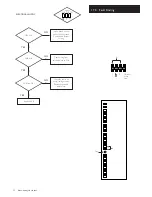

14.1

Annual Servicing

If a combustion analyser is available the CO/CO2 can be

checked (for levels see Section 4.0). If the the reading is

acceptable, and a visual inspection of the appliance is

satisfactory, it is not necessary to perform a full strip-

down.

IMPORTANT: When servicing ensure that both the gas

and electrical supplies to the boiler are isolated before

any work is started.

“The boiler cannot be switched off at the boiler,

therefore it is important to isolate the electrical supply at

the mains fuse.”

Hazardous materials are not used in the construction of

Baxi products, however reasonable care during service is

recommended.

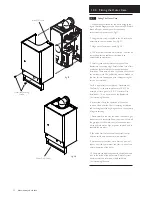

When replacing the combustion box door after servicing

it is essential that the retaining screws are tightened fully.

After Annual Servicing a combustion check should be

performed (see Section 14.1 paragraph 11).

1. For reasons of safety and economy, it is recommended

that the boiler is serviced annually. Before servicing please

read Section 1.2 Important Information.

2. After servicing, complete the relevant Service Interval

Record section of the Benchmark Commissioning

Checklist at the rear of this publication.

3. Ensure that the boiler is cool.

4.

Ensure that both the gas and electrical supplies to the

boiler are isolated.

5. Remove the outercase and lower door panel (see

Fitting the Outercase, Section 13.0).

WARNING: The PCB Control and Fan

Assembly are 325 Vdc. Isolate at supply

before access.

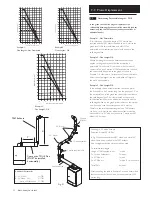

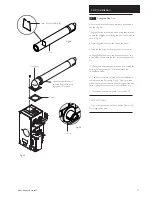

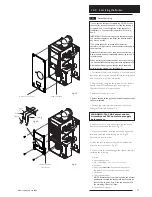

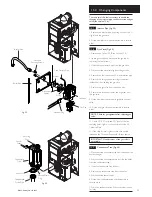

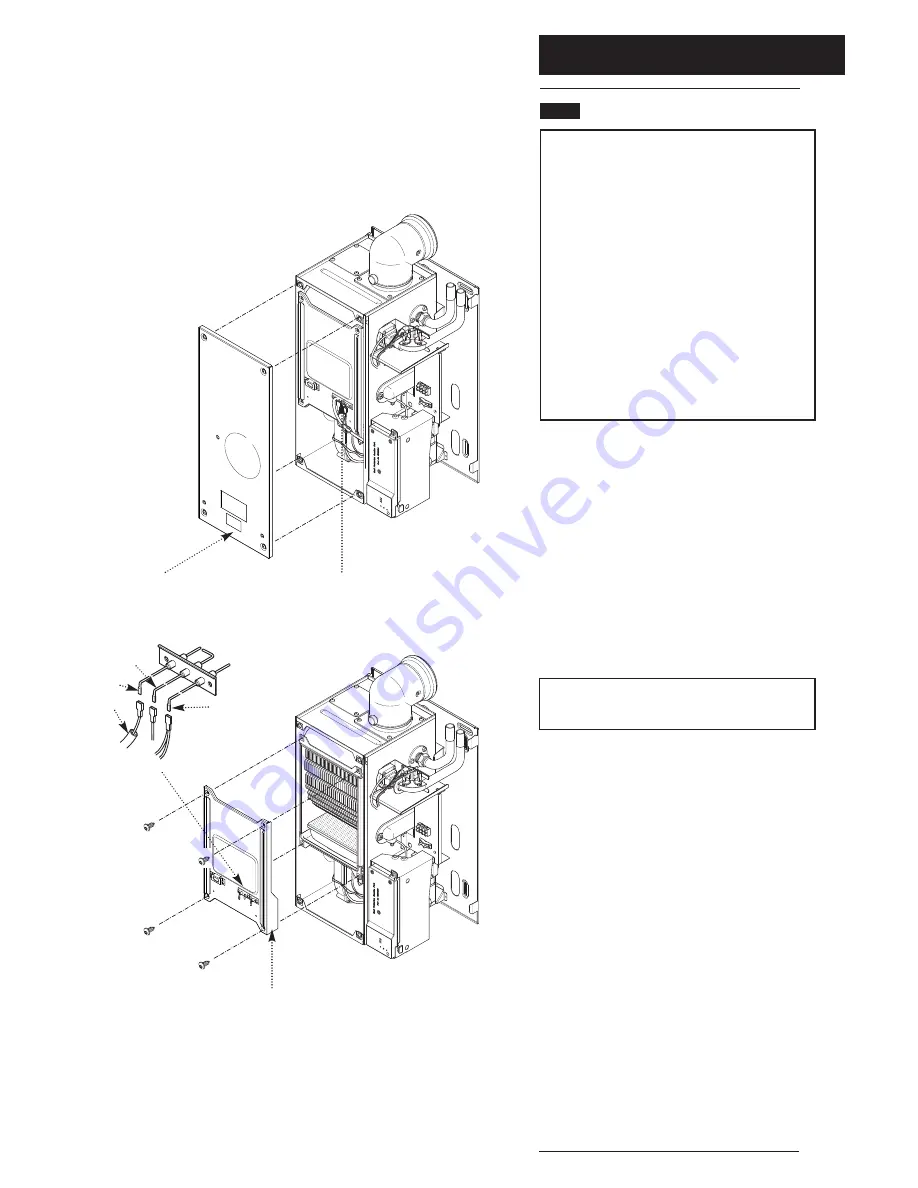

6. Release the four

1

/

4

turn screws securing the air box

door panel and remove the door (Fig. 39).

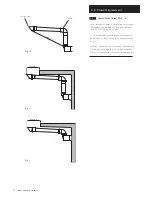

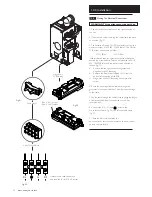

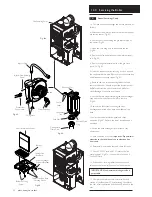

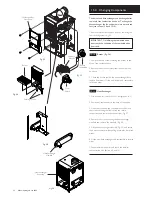

7. Disconnect the leads from the centre and right hand

terminals (earth and flame sensing probe) (Fig. 40).

Reconnect in reverse order.

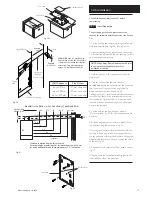

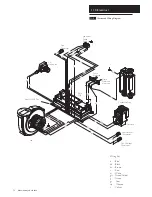

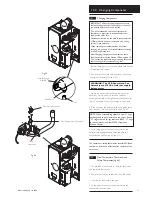

8. Undo the four screws securing the combustion box

door and remove the door (Fig. 41).

9. Visually check for debris/damage and clean or replace if

necessary the following:

a) Burner.

b) Heat exchanger fins.

c) Fan compartment

(Check also for condensate leaks).

d) Insulation.

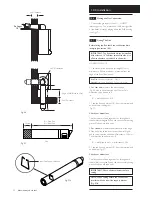

e) Door seals-

Important:

Pay particular attention to

the condition of the combustion box door seals.

f) Electrodes.

g) The condensate trap.

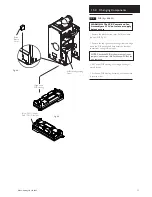

NOTE: Remove the trap drain plug and place a vessel

underneath to catch the condensate (care should be

taken as this could be hot). Clean the trap and refit

the drain plug. Check for leaks.

h) Top of heat exchanger.

Air Box Door Panel

Lead Terminals

Combustion Box

Door Panel

Fig. 39

Fig. 41

Fig. 40

Sensing

Earth

Spark

Sleeve