Publication No. 5105703

32

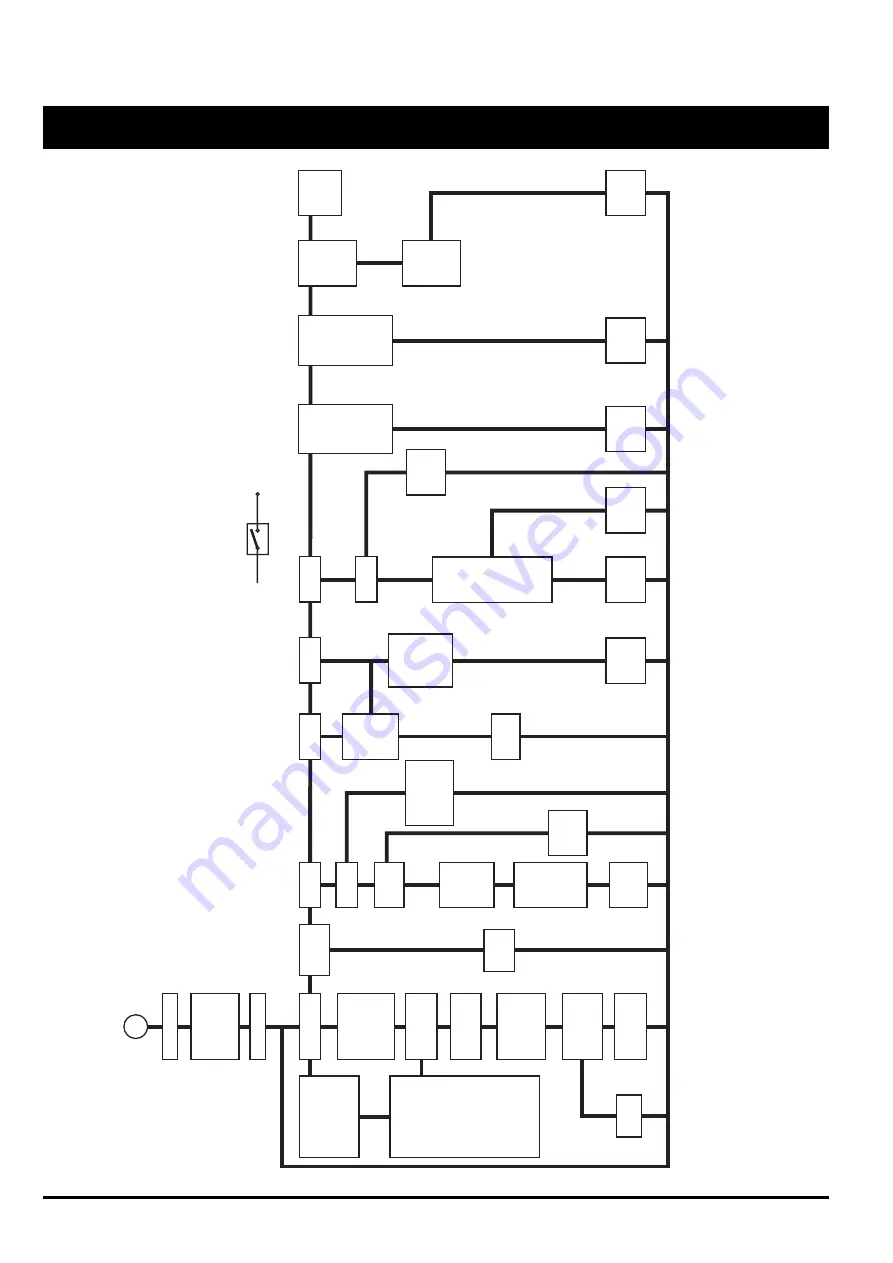

5. Fault Finding Guide

Fault Finding

Star

t

All ser

vice on

Ensure system

change-o

v

e

r

s

witch in control

bo

x is set

correctly

Call f

or heat

Ensure there is

240 10%

betw

een L & N

and 240v 10%

betw

een Swl

and N.

Has o

v

erheat

ther

mostat

oper

ated?

Chec

k fuse on,

electronic

control

Chec

k all

appliances

wir

ing and

electr

ical

components

.

Chec

k full oper

ational

sequence to ensure

that the boiler and

pump o

v

err

un

ther

mostat

are oper

ating correctly

Fully pumped

system.

Chec

k pump is

oper

ating and

w

ater is

circulating

correctly

.

Gr

a

vity DHW

system ensure

o

v

erheat

ther

mostat

b

ulb is located

correctly

see Fig.

21.

Press o

v

erheat

reset b

utton.

+_

+_

+_

Is there 240v

10% betw

een

T6 &

T2 on

electronic control?

Chec

k and/or

replace air

pressure s

witch

Replace

appropr

iate

ther

mostat.

See note

Replace

o

v

erheat

ther

mostat

Replace

pump

o

v

err

un

ther

mostat

Boiler

oper

ating

satisf

actor

y

Flame Super

vision

T

esting

With the boiler r

unning, tur

n off at the boiler ther

mostat.

T

empor

ar

ily restr

ict the pilot gas supply b

y

fully scre

wing in the

gas v

alv

e pilot scre

w cloc

kwise

. T

u

rn

on at the boiler ther

mostat:

a spar

k will be present, indicating GV2 is electr

ically disconnected,

and the boiler will not light.

No

w reinstate the pilot supply (three

complete anti-cloc

kwise tur

ns);

pilot and main boiler will light in the

nor

mal manner

.

T

est Pr

ocedure For Measuring Flame Current

Disconnect the white wire from GV2 on gas control v

alv

e and

connect it via a suitab

le test s

witch to neutr

al as sho

wn.

Set

test s

witch to OFF

. Inser

t an appro

v

ed ammeter in ser

ies

with the spar

k electrode

.

T

u

rn

ON the electr

icity supply and restar

t the boiler

.

NO

TE:

The pilot will light b

ut not the main b

u

rner as GV2 is

disconnected.

When the pilot is estab

lished set the test s

witch to ON.

This

will stop the spar

k and allo

w a steady flame current to be

measured.

NO

TE:

When pumped centr

al heating is

in oper

ation the boiler is controlled b

y

the

main boiler ther

mostat.

When only a g

ra

vity hot w

ater circuit is in

oper

ation the boiler is controlled b

y

the

main boiler ther

mostat when set at No

.4

or belo

w

. At setting abo

v

e

No

.4 the

temper

ature is limited b

y

the oper

ation

of the g

ra

vity control ther

mostat.

Are all

v

alv

es

open and

w

ater

circulating

correctly

T

est

Switch

White wire

disconnected

from GV2

N

F

ault Finding Char

t

Chec

k that

pilot is not

par

tially

b

loc

k

ed.

Chec

k

solenoid

GV1 replace

if necessar

y

Replace

electronic

control

Does main

b

u

rner light?

Does spar

k

stop?

Switch off

e

xter

nal

electr

icity

supply and

follo

w the

test

procedure

descr

ibed

abo

v

e

.

Is there

more than

1.5µA

recorded?

If gas is not

flo

wing out

of pilot, chec

k

jet is not

b

loc

k

ed & pilot

scre

w on gas

v

alv

e open

Chec

k

solenoid

GV2 replace

if necessar

y

Does boiler

cycle off and

on under

control of

the boiler

ther

mostat

when system

is up to

temper

ature

.

See note

F

ollo

wing a

run per

iod at

maxim

um

temper

ature

,

does pump

contin

ue to

oper

ate after

boiler

ther

mostat

oper

ates?

Boiler

oper

ate

without

tr

ipping the

o

v

erheat

ther

mostat?

Fully pumped

system only

Does Pilot

light?

Replace

electronic

control

Chec

k case door

seal and replace

if damaged.

Fully

tighten tw

o lo

w

e

r

secur

ing scre

ws

.

Is electrode

spar

king?

Is case door

leaking?

Are spar

ks

occurr

ing

else

where?

Is there

240v 10%

betw

een T2

and T4

on electrode

control

Ensure air

pressure

tubes are

not kink

ed

or b

loc

k

e

d

and are

correctly

fitted.

Chec

k and/

or replace

air pressure

s

witch

Chec

k and/

or replace

electrode

lead

Does f

a

n

oper

ate?

Does f

an r

u

n

without

cycling on/off

Replace

electronic

control

PRF0034A

Replace

fa

n

Does Pilot

remain lit?

Ye

s

Y

e

s

Ye

s

Ye

s

Ye

s

Y

e

s

Ye

s

Y

e

s

Ye

s

Ye

s

Ye

s

Y

e

s

Ye

s

Ye

s

Ye

s

Ye

s

Ye

s

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

+_

Is there

240v 10%

betw

een

T2 &

T3 on

electronic

control?

+_

Fig. 31