Installation Requirements - Page 11

Table 2. Air Supply

1.5

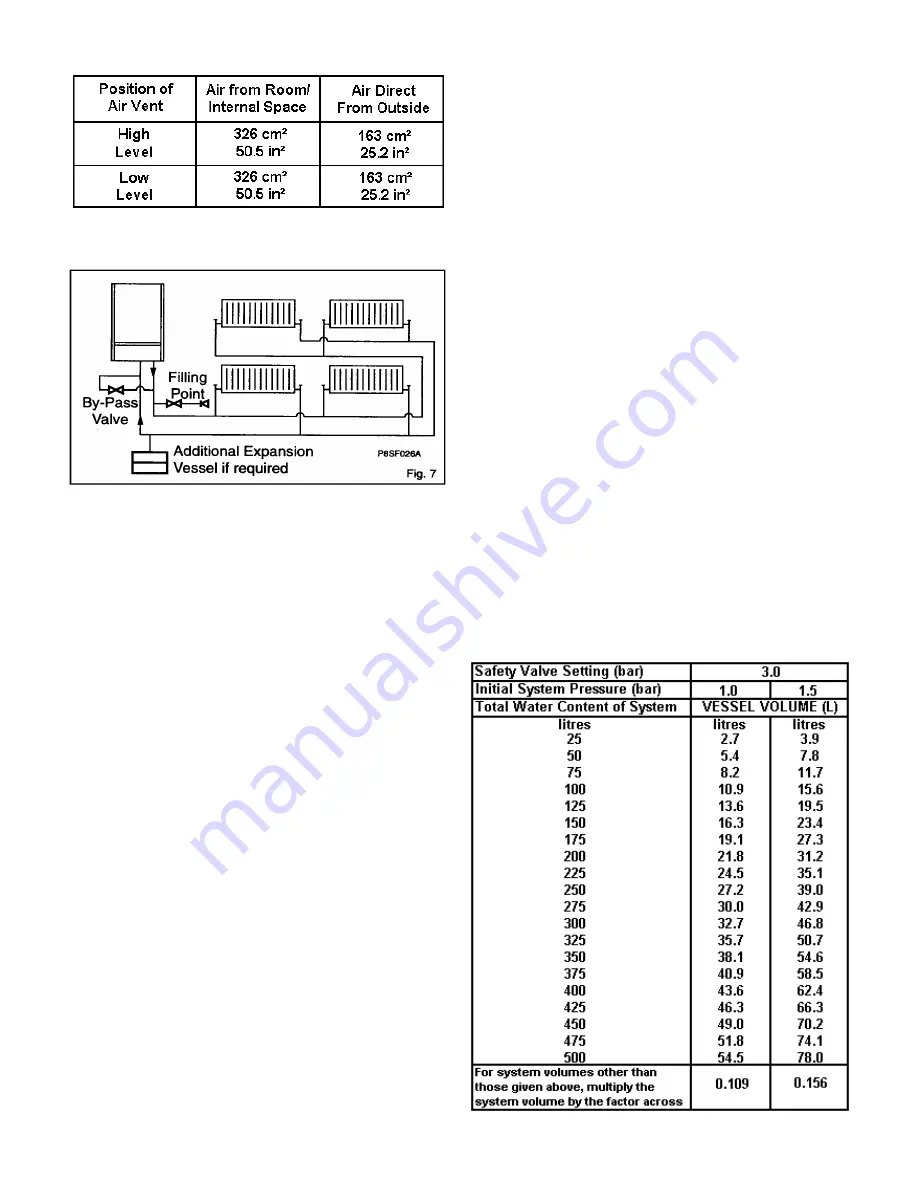

Guide to System Requirements

(Figs. 7 & 9)

These combination boilers are specifically designed for

sealed systems

only. Therefore the central heating system

should be in accordance with the relevant recommendations

given in BS 6798 and also, smallbore and microbore

systems BS 5449 Part 1.

For correct operation the boilers require a by-pass.

A valved by-pass should be fitted and the flow reduced to

balance the system correctly. The length of the by-pass

pipework is not important.

Note:

If the by-pass flow is reduced too much this will cause

the appliances to overheat and go to lockout.

The installation should be designed to work with flow

temperatures of up to 90°C. All components of the system

must be suitable for a maximum pressure of 3 bar (45 psi)

and a temperature of 110°C.

The following components are incorporated within the

appliance.

a)

Circulating pump*.

b)

Diverter valve.

c)

Pressure Relief valve with a non-adjustable pre-set lift

pressure of 3 bar (45 psi).

d)

Pressure gauge covering the range 0-4 bar (0-60 psi).

e)

10 litre expansion vessel with initial charge pressure of

1.0 bar (14 psi).

f)

Domestic Hot Water flow switch.

*

The pump supplied is sufficiently powerful for

heating requirements upto 24kW providing the

designed temperature drop across the heating

system is above 17°C (see pump performance

curve).

The central heating output from the boiler can easily be

downrated if a lower temperature drop across the system is

prefered.

If the central heating system requires an increased pump

head a second circulating pump should be installed. The

pump must be sited on the return to the boiler and

electrically connected using a proprietry relay i.e. Drayton

RB1 - see Section 2.6.

The domestic hot water system must be in accordance with

the relevant recommendations of BS 5546. Copper tubing to

BS 2871:1 is recommended for water carrying pipework and

MUST be used for pipework carrying potable water. All

capillary joints in the D.H.W pipework must be joined with a

lead free solder.

Ancillary pipework, not forming part of the useful heating

surface, should be lagged to prevent heat loss and any

possible freezing, particularly where pipes run through roof

spaces and ventilated under-floor spaces.

If the capacity of the central heating system should exceed

100 litres, an additional vessel should be installed on the

return to the combination boiler from the heating system

(Fig. 7). Guidance on vessel sizing is given in Table 3.

To allow the maximum central heating expansion capacity in

the boiler the pre-charge pressure in the central heating

expansion vessel must be marginally greater than the initial

(cold) system pressure at the appliance (as shown on the

appliance pressure gauge).

Draining taps should be at least 1/2 in BSP nominal size and

be in accordance with BS 2879.

Table 3. Expansion Vessel Requirements

Deduct from the value given in the table the

10 litre expansion vessel supplied.

Summary of Contents for 80e

Page 5: ...Optional Extras Page 5 ...

Page 6: ...Optional Extras Page 6 Installation instructions included as necessary with each kit ...

Page 7: ...Optional Extras Page 7 Installation instructions included as necessary with each kit ...

Page 12: ......

Page 28: ...Routine Maintenance Page 27 ...

Page 30: ...Routine Maintenance Page 29 ...

Page 34: ...Component Replacement Page 33 ...

Page 35: ...Component Replacement Page 34 ...

Page 43: ...7 1 Control Flow Sequence Permanent Pilot Page 42 ...

Page 44: ...7 2 Functional Flow Permanent Pilot Page 43 ...

Page 45: ...7 3 Fault Finding Permanent Pilot Page 44 ...

Page 46: ...7 4 Electrical Diagram Permanent Pilot Page 45 ...

Page 47: ...8 1 Control Flow Sequence Electronic Page 46 ...

Page 48: ...8 2 Functional Flow Electronic Page 47 ...

Page 49: ...8 3 Fault Finding Electronic Page 48 ...

Page 50: ...8 4 Electrical Diagram Electronic Page 49 ...