Boiler Installation - Page 18

2.5

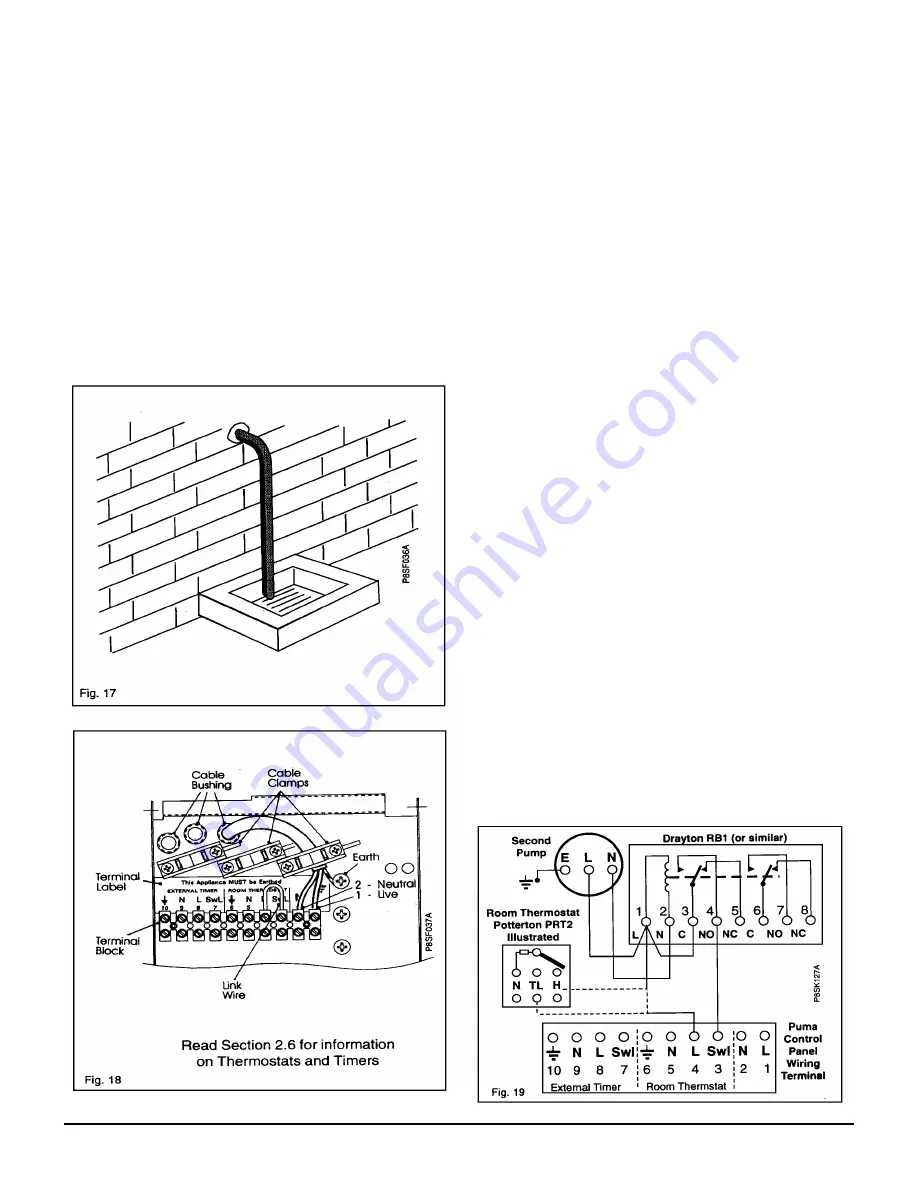

Pressure Relief Valve

The pressure relief valve is pre-set at 3 bar.

Install a pressure relief valve discharge pipe, not less than

15 mm diameter and connect to the pressure relief outlet

connection using a 15mm Compression fitting. The pipe run

should be as short as possible, run continuously downwards

and discharge to the outside of the building, where possible

over a drain. The pipe end should be directed towards the

wall. (Fig. 17) The discharge point must be such that it will

not be hazardous to occupants or cause damage to external

electrical components or wiring.

IT MUST NOT DISCHARGE ABOVE AN ENTRANCE, OR

WINDOW, OR ANY TYPE OF PUBLIC ACCESS. THE

INSTALLER MUST CONSIDER THAT THE OVERFLOW

COULD DISCHARGE BOILING WATER.

Read Section 2.6 for information on Thermostats and Timers

2.6

Wiring the Appliance

The internal wiring of the appliance is shown in Figs. 42 & 46

. The wiring diagram is also on the inside of the front casing

panel.

a) Undo the single retaining screw on the top of the controls

panel and allow the panel to swing down.

b) Using PVC insulated cable of not less than 0.75 mm².

(24/0.2mm to BS 6500 Table 16), wire up the panel

referring to the termination label. (Fig. 18).

Note:

Ensure that all cables pass through the wiring panel

bush/s and are securely fixed by the cable clamp/s.

If a room thermostat is to be fitted, remove the Red link wire

between terminals 3 and 4 and discard prior to wiring in the

thermostat. If no room thermostat is to be fitted retain link

wire.

If a programmable room thermostat is to be used it must be

fitted in place of the external timer and the link between 3 &

4 retained.

If the installation does not have an internal or external timer

the central heating switch on the front of the appliance must

be set to Constant during periods when central heating is

required.

If using an internal timer connect the timers lead to PL11 on

the modulation control board. (Fig. 30).

If an external frost thermostat is required it should be

connected to terminals 3 and 8. For the frost thermostat to

function the boiler switch must be set to 'On'.

Secondary Pump

.

If a second pump is to be fitted to the

central heating system it should be sited on the return to the

boiler and electrically connected using a proprietary relay as

shown in Fig. 19.

c)

Check all wiring and reposition the control panel.

d)

Secure with screw provided.

Note:

The electrical mains supply must be fused at 3 A, and

the connection must be made to the wiring panel in such a

way that should the lead disengage from the cable clamp,

the current carrying conductors become taut before the earth

conductor.

Summary of Contents for 80e

Page 5: ...Optional Extras Page 5 ...

Page 6: ...Optional Extras Page 6 Installation instructions included as necessary with each kit ...

Page 7: ...Optional Extras Page 7 Installation instructions included as necessary with each kit ...

Page 12: ......

Page 28: ...Routine Maintenance Page 27 ...

Page 30: ...Routine Maintenance Page 29 ...

Page 34: ...Component Replacement Page 33 ...

Page 35: ...Component Replacement Page 34 ...

Page 43: ...7 1 Control Flow Sequence Permanent Pilot Page 42 ...

Page 44: ...7 2 Functional Flow Permanent Pilot Page 43 ...

Page 45: ...7 3 Fault Finding Permanent Pilot Page 44 ...

Page 46: ...7 4 Electrical Diagram Permanent Pilot Page 45 ...

Page 47: ...8 1 Control Flow Sequence Electronic Page 46 ...

Page 48: ...8 2 Functional Flow Electronic Page 47 ...

Page 49: ...8 3 Fault Finding Electronic Page 48 ...

Page 50: ...8 4 Electrical Diagram Electronic Page 49 ...